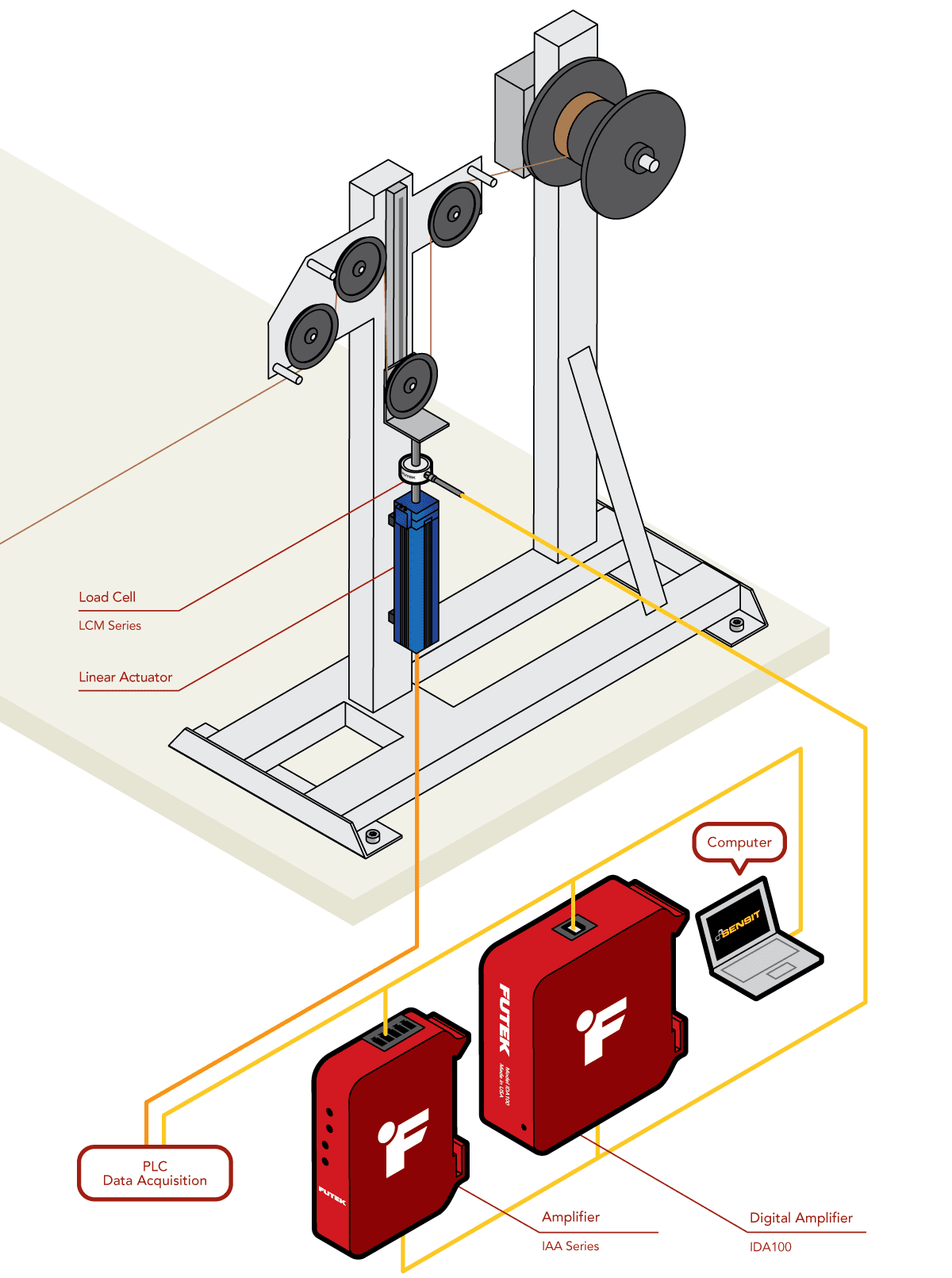

Whether you are feeding a wire EDM machine, a wire stripper, or winding

electric motor coils, precision wire tension is key in meeting today’s

high-performance standards. The key to precision wire tension control

requires live monitoring of the wire tension. By utilizing a load cell

in-line with the wire tensioner, a versatile wire tensioning system can

be developed that can adapt to changing wire quality and conditions.

This adaptive system can maintain high coil winding quality and

repeatability while maximizing process efficiency by preventing wire

breakage.

How it Works

An LCM Series Miniature In Line Load Cell is mounted in-line between the wire tensioner and a linear actuator to measure wire tension.

Adjusting the linear actuator piston causes changes in wire tension which generates a signal in the LCM series load cell.

The signal from the LCM series load cell is then sent to the IAA series Analog Amplifier or IDA100 Digitally Configurable Amplifier.

The amplified signal is then fed into a PLC/Motion Controller which drives the liner actuator, closing the control loop, and allowing the system to actively adapt to changing wire conditions.

With the IDA100, amplifier output can be simultaneously monitored and adjusted on a Windows PC with FUTEK’s SENSIT™ software while providing high speed, amplified, analog output.

Products in Use

One Miniature In Line Load Cell (LCM Series) paired with Instrumentation (IAA Series or IDA100).

Contact Us

All FUTEK application illustrations are strictly conceptual.

Please Contact Us with questions.

Please Contact Us with questions.

Whether you are feeding a wire EDM machine, a wire stripper, or winding

electric motor coils, precision wire tension is key in meeting today’s

high-performance standards. The key to precision wire tension control

requires live monitoring of the wire tension. By utilizing a load cell

in-line with the wire tensioner, a versatile wire tensioning system can

be developed that can adapt to changing wire quality and conditions.

This adaptive system can maintain high coil winding quality and

repeatability while maximizing process efficiency by preventing wire

breakage.