Characterization of solid, liquid, and hybrid rocket engines is often performed with computer modeling and ground testing. For experimental fuels, aerospike and other experimental altitude compensating nozzles, ground testing is necessary to characterize their thrust curves and Isp in static testing conditions. To accomplish this an LCF series load cell is mated between the rocket engine and the thrust test stand. In addition to thrust, by incorporating four, 3-axis load cells in the rocket motor test stand base supports, engine mass flow can be directly measured and under certain circumstances vectored exhaust thrust can also be measured. Rocket Engine Thrust Stand inspired by Swiss Propulsion Laboratory SPL's design.

How it Works

In this rocket engine thrust stand application, the rocket engine is threaded into the LCF series universal load cell.

The rocket engine test stand mount prevents any side loading on the cell, ensuring the load cell is only receiving axial loads.

The load cell assembly is mounted to a fixed thrust measurement test stand securing the engine (rocket test stand).

In line with the base supports, MTA400/MTA600 multi-axis load cells are installed.

As the engine is operating, thrust is measured with the LCF series load cells.

Mass flow and Drag(aka “kick”) are captured with MTA400/MTA600 load cells.

Thrust data can be live streamed and logged for monitoring and later review and comparison against simulated models with USB220 and SENSIT

Mass flow data from all 4 multi-axis load cells are captured, streamed and logged with USB220 and SENSIT.

Each axis of the MTA400/MTA600 is captured with a separate USB220.

Load cell output can also be amplified via the IAA series for capture by pre-existing DAQs.

Products in Use

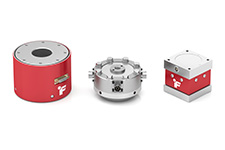

FUTEK’s Universal Load Cell (LCF Series) mated with instrumentation (IAA Series or USB220) and 4 of FUTEK’s MTA400/MTA600 Multi-Axis load cells each paired with 3 IDA100 digital amplifiers.

Contact Us

All FUTEK application illustrations are strictly conceptual.

Please Contact Us with questions.

Please Contact Us with questions.

Characterization of solid, liquid, and hybrid rocket engines is often performed with computer modeling and ground testing. For experimental fuels, aerospike and other experimental altitude compensating nozzles, ground testing is necessary to characterize their thrust curves and Isp in static testing conditions. To accomplish this an LCF series load cell is mated between the rocket engine and the thrust test stand. In addition to thrust, by incorporating four, 3-axis load cells in the rocket motor test stand base supports, engine mass flow can be directly measured and under certain circumstances vectored exhaust thrust can also be measured. Rocket Engine Thrust Stand inspired by Swiss Propulsion Laboratory SPL's design.