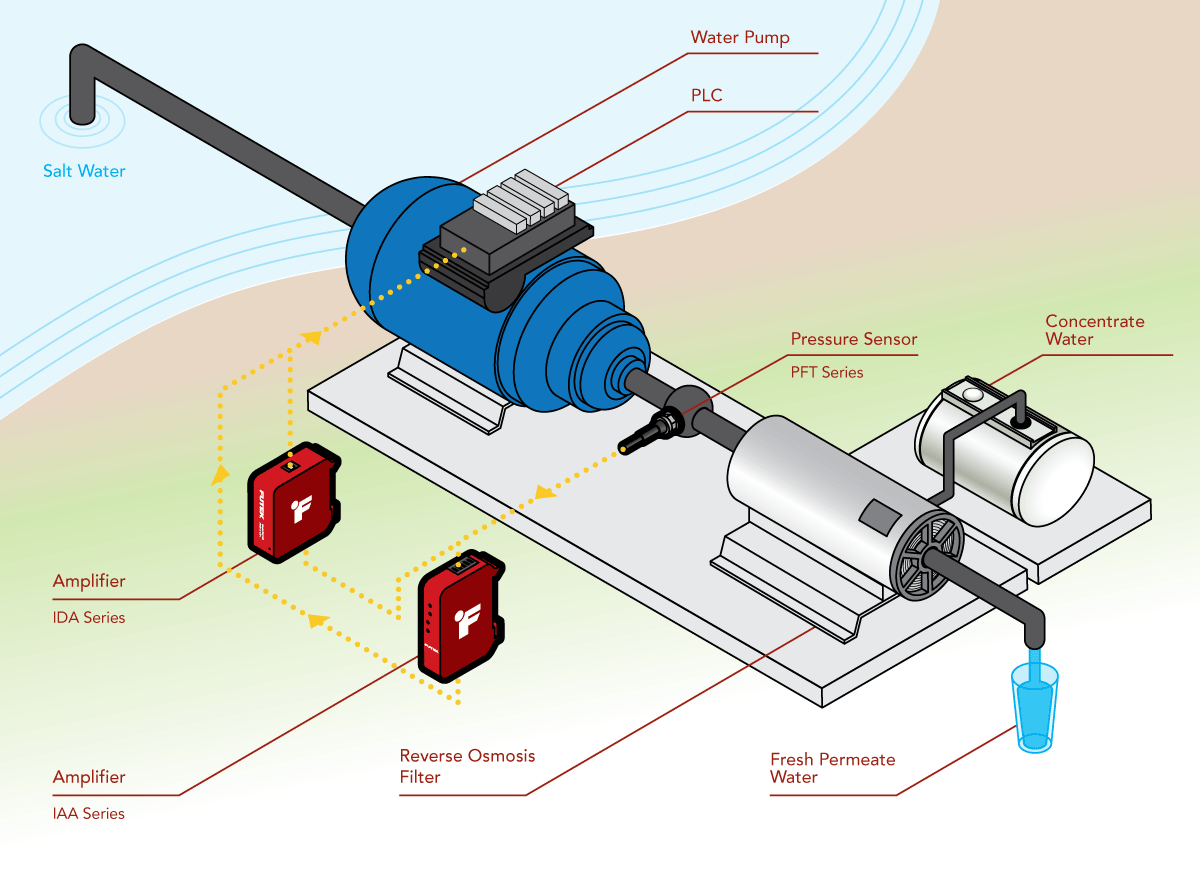

Access to clean drinking water is a necessity for every individual

around the world. In many drought-stricken areas, freshwater is limited

while saltwater from the ocean is abundant and plentiful. Converting

saltwater into freshwater is most commonly performed through

high-pressure reverse osmosis. These systems require constant pressure

delivered from a system of pumps to maintain membrane health and

maximize system efficiency. By incorporating a pressure sensor into a

control loop control system, the pump can maintain a constant operating

pressure for maximum efficiency.

How it Works

A PFT510 miniature pressure sensor is inserted between the water pump output and reverse osmosis filter input.

The output signal from the pressure sensor is amplified with the IAA series or IDA100 amplifier and fed into a PLC.

The PLC regulates the motor output in response to changing pressures maintaining a constant output pressure.

By maintaining a consistent pressure, filter life is increased and system efficiency is maximized.

Additionally, with the IDA100, amplifier output can be monitored and adjusted accordingly over USB connection with FUTEK's SENSIT™ software.

Products in Use

FUTEK's PFT510 Miniature Flush Mount Pressure Sensor paired with Instrumentation (IAA Series or IDA100 Amplifiers)

Contact Us

All FUTEK application illustrations are strictly conceptual.

Please Contact Us with questions.

Please Contact Us with questions.

Access to clean drinking water is a necessity for every individual

around the world. In many drought-stricken areas, freshwater is limited

while saltwater from the ocean is abundant and plentiful. Converting

saltwater into freshwater is most commonly performed through

high-pressure reverse osmosis. These systems require constant pressure

delivered from a system of pumps to maintain membrane health and

maximize system efficiency. By incorporating a pressure sensor into a

control loop control system, the pump can maintain a constant operating

pressure for maximum efficiency.