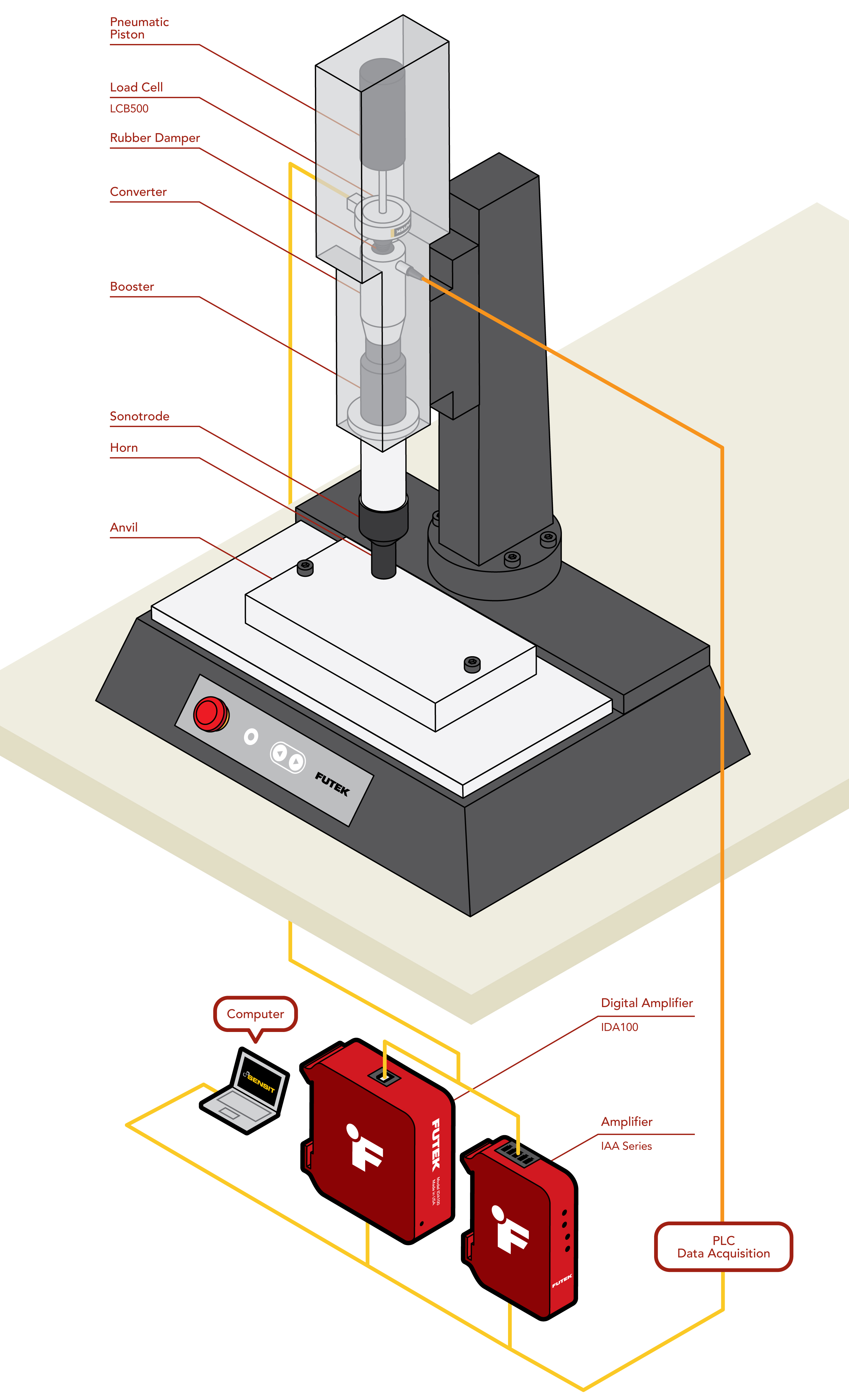

Ultrasonic Welding welds together two pieces of material (ex: plastic)

using high frequency vibrations. This results in a clean welding

process, producing uniform, fluid tight welds. The clean welding process

makes it ideal for medical equipment, toys, semiconductors, and

consumer electronics. One of the keys to a clean weld is the proper

application of clamping force. Too little force results in an incomplete

weld, too much force results in deformed parts. Incorporating a load

cell inline with the welding stack enables the ultrasonic welder to

provide the correct amount of contact force to every part.

How it Works

A LCB/LCF Series Load Cell is mounted between the converter and the actuator that moves the assembly/stack.

A dampener is placed between the converter and LCB/LCF load cell to minimize the effects of high speed vibrations on the sensor.

As the assembly clamps the parts together, the LCB/LCF load cell measures the welding and hold time clamping forces.

The IAA Series and IDA100 amplify and transmit the load cell signal to the welder's PLC enabling closed loop clamping force control.

Additionally, the IDA100 enables logging and monitoring of the load cell output via a PC with SENSIT™ Software.

The data generated via our SENSIT™ software can then be used for IoT and production traceability operations.

Products in Use

One LCB500 Tension and Compression Load Cell paired with Instrumentation (IAA Series or IDA100)

Contact Us

All FUTEK application illustrations are strictly conceptual.

Please Contact Us with questions.

Please Contact Us with questions.

Ultrasonic Welding welds together two pieces of material (ex: plastic)

using high frequency vibrations. This results in a clean welding

process, producing uniform, fluid tight welds. The clean welding process

makes it ideal for medical equipment, toys, semiconductors, and

consumer electronics. One of the keys to a clean weld is the proper

application of clamping force. Too little force results in an incomplete

weld, too much force results in deformed parts. Incorporating a load

cell inline with the welding stack enables the ultrasonic welder to

provide the correct amount of contact force to every part.