What is Wire Pull Test?

The quality of a wire bond test depends on the mechanical strength of the joint as well as its electrical conductivity. Wire pull testing or wire bond testing is a technique used to evaluate the bond quality and strength in microelectronic applications.

Wire pull test applies an upward force upon wires and effectively pulls the wire away from the substrate or die by a hook until there’s either a bond failure or the wire breaks. The objective of wire bond test is to measure bond strength, evaluate bond failure modalities, or determine compliance with specified bond strength requirements.

Common Wire Bond Test Applications

Semiconductor Defect Analysis & Characterization.

Wire Bond Testing.

Validation Of Process & Machine Setup.

In-Process Quality Control.

Wire Bond Strength Analysis.

Materials Testing.

Ribbon Pull.

Vector Pull.

Industry Wire Pull Test Standards

MIL-STD-883: Method 2011.7 Bond Strength (Destructive Bond Pull Test)

MIL-STD-883: Method 2023.5 Nondestructive Bond Pull

IPC-TM-650: TEST METHODS MANUAL

Why FUTEK load cells is suitable for your wire pull test application?

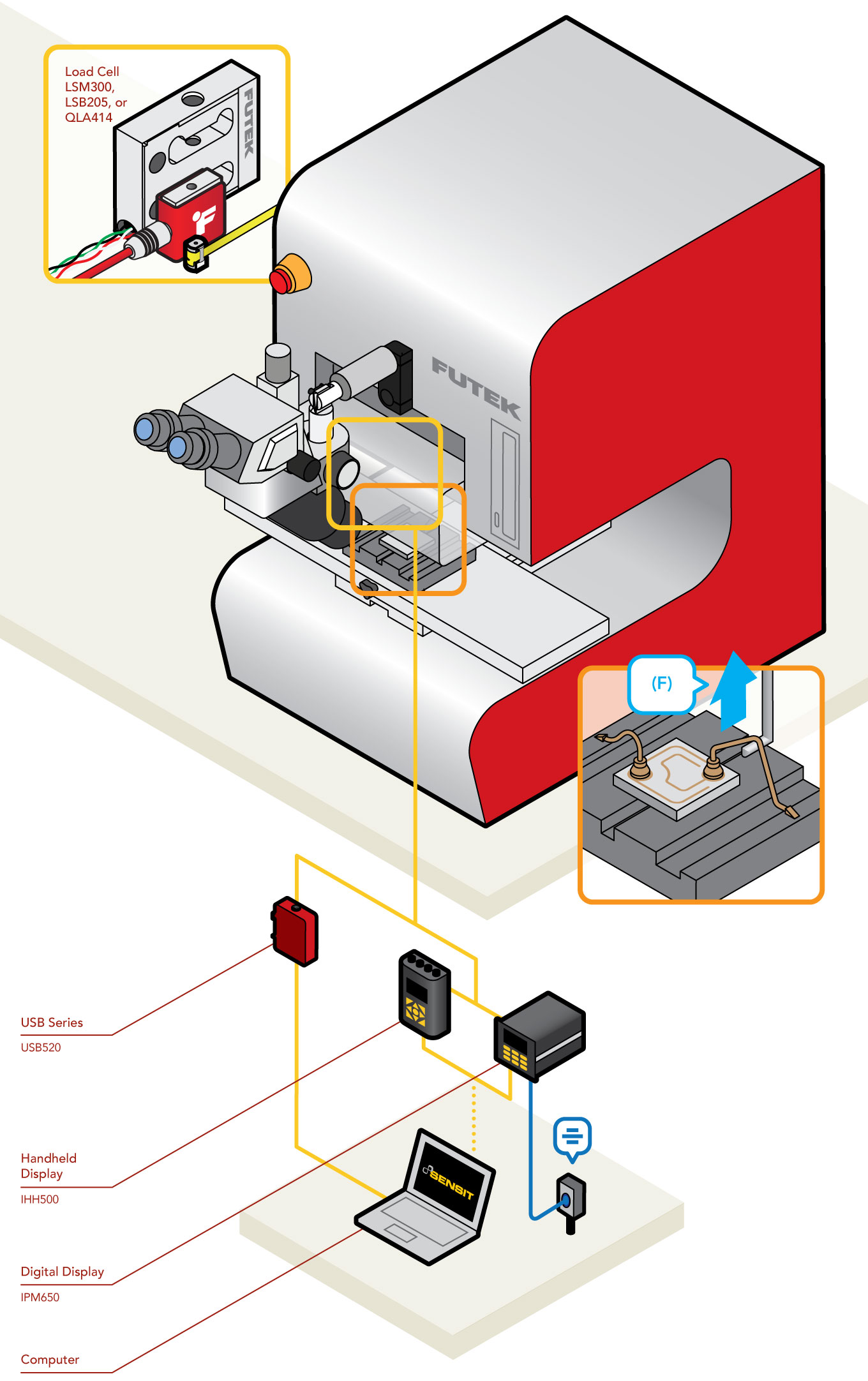

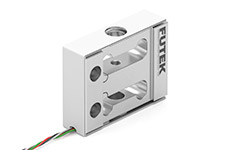

The force sensor used in the wire pull measurement is critical. An automated wire bond testing system is as precise as its core element: the load cell (i.e. force sensor). FUTEK’s LSM300 or LSB205 can be integrated into the cartridge mechanism in order to accurately record the peak force or breaking force of the wire bond.

How it Works

Wire bond testing systems enables two types of wire pull testing: destructive and non-destructive.

During a destructive wire pull test, a wire is pulled upward (perpendicular to the substrate) by a hook until there is either a bond failure or the wire breaks. This type of test is intended for process setup.

During a non-destructive wire pull test, a wire is pulled upward (perpendicular to the substrate) by a hook at a predesignated force to ensure high reliability packaging.

Wire bond testing systems also have the ability to perform the following test: Solder Ball Shear, Die Shear, Stud Bump Pull, Passivation Layer Shear, Ribbon Pull, Tweezer Peel, Fatigue and Push.

Specifically during a wire pull test FUTEK’s LSM300 precision load cell or LSB200 miniature load cell can be attached to the hook tool to measure the pulling force exerted on the wire under test.

These force measures can be streamed to a computer for analysis utilizing FUTEK’s USB Solutions.

Products in Use

OEM Load Cell or Jr. Miniature S-Beam Load Cell (LSM300 or LSB205) paired with Instrumentation (USB Solutions).

Contact Us

All FUTEK application illustrations are strictly conceptual.

Please Contact Us with questions.

Please Contact Us with questions.

What is Wire Pull Test?

The quality of a wire bond test depends on the mechanical strength of the joint as well as its electrical conductivity. Wire pull testing or wire bond testing is a technique used to evaluate the bond quality and strength in microelectronic applications.

Wire pull test applies an upward force upon wires and effectively pulls the wire away from the substrate or die by a hook until there’s either a bond failure or the wire breaks. The objective of wire bond test is to measure bond strength, evaluate bond failure modalities, or determine compliance with specified bond strength requirements.

Common Wire Bond Test Applications

Semiconductor Defect Analysis & Characterization.

Wire Bond Testing.

Validation Of Process & Machine Setup.

In-Process Quality Control.

Wire Bond Strength Analysis.

Materials Testing.

Ribbon Pull.

Vector Pull.

Industry Wire Pull Test Standards

MIL-STD-883: Method 2011.7 Bond Strength (Destructive Bond Pull Test)

MIL-STD-883: Method 2023.5 Nondestructive Bond Pull

IPC-TM-650: TEST METHODS MANUAL

Why FUTEK load cells is suitable for your wire pull test application?

The force sensor used in the wire pull measurement is critical. An automated wire bond testing system is as precise as its core element: the load cell (i.e. force sensor). FUTEK’s LSM300 or LSB205 can be integrated into the cartridge mechanism in order to accurately record the peak force or breaking force of the wire bond.