We dig, break the rules, and reinvent because we are experimenters. Through experimentation, we move forward.

FUTEK is proud of the reputation we’ve established as a quality source for sensor solutions and electronics over the past 27 years. And yes, we do work hard to maintain that reputation, but we work even harder to improve it. Our goal has always been to produce trusted products. This is why we do things a bit differently around here. We often break rules because we believe there are always better solutions to be discovered. We constantly research because our curiosity has often led us to novel inventions. We run our products through extensive test and trials to provide proof of our reliability to those who choose to partner with us. Best described, we are a team of technology experimenters, internally driven towards progression.

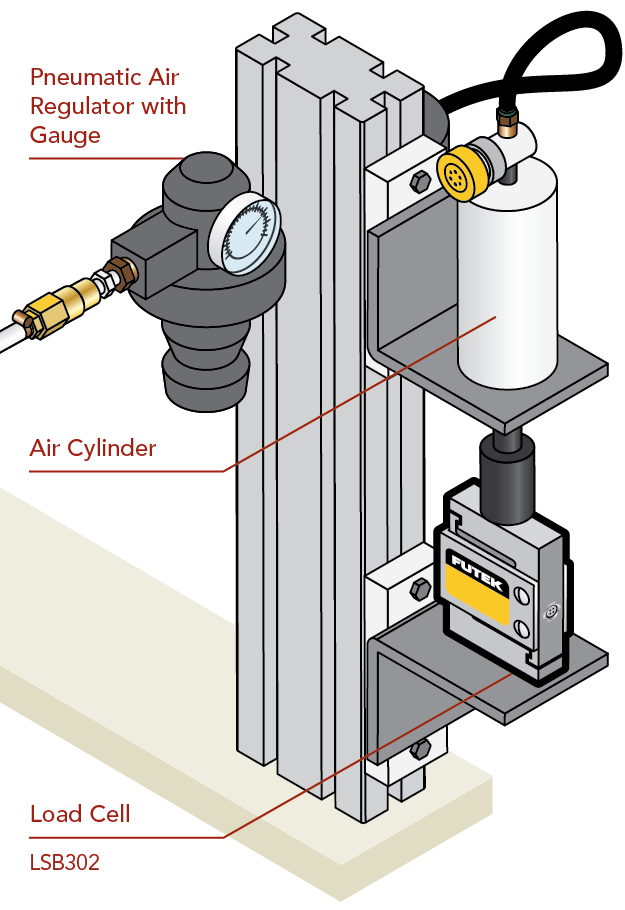

Over a decade ago we broke new ground with an experiment here at FUTEK. The purpose was to put our LSB302 (100 lb. S-Beam Load Cell) under an accelerated test. The plan was to subject the LSB302 to conditions - stress, strain, and overload - in excess of its normal service parameters in effort to uncover faults in an expedited amount of time. Little did we know that the unit under test would withstand these conditions without difficulty. After years and years of non-stop accelerated overload we prepare for a landmark moment at the FUTEK headquarters. On June 1st, 2015, the unit under test will hit a BILLION cycles of overloaded compression. More impressive than that, the unit is still meeting procurement specifications.

LSB302 Specifications:

- Capacity Range: 25 lb. to 300 lb.(111 to 1334 N)

- Safe Overload: 1000% (25 to 100 lb.), 500% (200 to 300 lb.)

- Nonlinearity: ± 0.5% of Rated Output

- High Endurance

This means a lot to the FUTEK team because it exemplifies our high-standard of quality. Integration of our long-lasting products enables end-users to enjoy slim to none mean times to repair (MTTR). Low to non-existent MTTR means high system availability of your application platform. System availability, a key measure influencing customer satisfaction, is directly affected by component reliability of the individual subassemblies. When components fail the system is no longer available to perform its function and must be repaired to bring it back to operational readiness. This gets into the associated field of maintainability. Hardly ever will you go through the laborious process of maintenance and repair with a FUTEK load cell. Our products are built to last so that your applications continue to run without interruptions. Altogether, investing in high reliability components in the beginning pays lifelong dividends in terms of availability and total system life-cycle-cost.

More About Our Reliability Test Stand

FUTEK constructed a pneumatic test stand to extensively test the fatigue rate of our LSB302 S-Beam Load Cell. The pneumatic cylinder is designed to deliver compressive force onto the unit under test. The test conducted on the LSB302 began in August of 2001 with the unit being loaded at 3 cycles per second to 113% of rated output. As the life test reached 180 million cycles, the load was increased to 150% of rated output. Nearly 15 years later the S-Beam Load Cell LSB302 is still going strong and showing no signs of fatigue.

It is also important to understand that the test exemplifies the reliability of the entire system, not just the flexure. Everything is under test including the flexure, gauges, wiring, solder joints, terminals, adhesives, curing and coatings, that includes every element in the system that could cause a failure.

Let's just say this accomplishment has been awesome to watch unfold. The LSB302 is very representative of load cells produced by FUTEK, so this accomplishment serves as sustainable proof of the reliability built into the company's product.

We are proud and overwhelmingly honored to be a dependable partner of the tech industry. Taking on projects with some of the most forward-thinking technology companies in the industry is what drives FUTEK to continuously exceed the limits of what is normally done.

Find out more: