How to Calibrate Button Load Cell | FUTEK

Button Load Cell Calibration is an adjustment or set of corrections that are performed on a load button, or instrument (amplifier), to make sure that the sensor operates as accurately, or error-free, as possible.

Every load button is prone to measurement errors. These structural uncertainties are the simply algebraic difference between the value that is indicated by the sensor output versus the actual value of the measured variable, or known reference loads. Measurement errors can be caused by many factors:

An offset means that the sensor output at zero load (true zero) is higher or lower than the ideal output. Additionally, zero stability relates to the degree to which the transducer maintains its zero balance with all environmental conditions and other variables remaining constant.

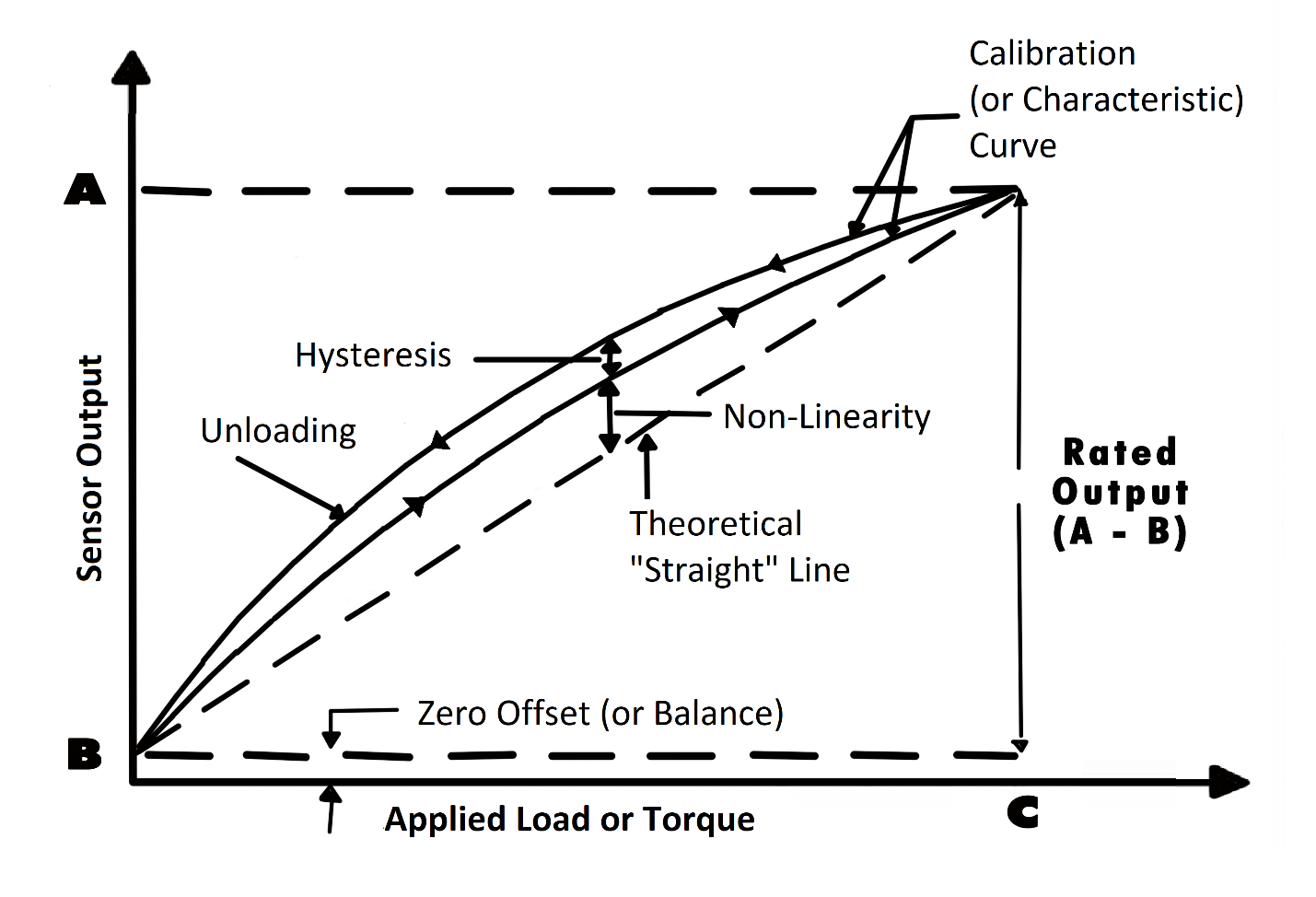

Few force sensors have a completely linear characteristic curve, meaning that the output sensitivity (slope) changes at a different rate throughout the measurement range. Some are linear enough over the desired range and does not deviate from the straight line (theoretical), but some sensors require more complex calculations to linearize the output. So, load button non-linearity is the maximum deviation of the actual calibration curve from an ideal straight line drawn between the no-load and rated load outputs, expressed as a percentage of the rated output.

The maximum difference between transducer output readings for the same applied load; one reading is obtained by increasing the load from zero and the other by decreasing the load from the rated output. It usually measured at half rated output and expressed as a percentage of the rated output. Measurements should be taken as rapidly as possible to minimize creep.

The maximum difference between transducer output readings for repeated loadings under identical loading and environmental conditions. It translates into the load cell's ability to maintain consistent output when identical loads are repeatedly applied.

The change in output and zero balance, respectively, due to a change in transducer temperature.

Each force sensor has a "characteristic curve" or a "calibration curve", which defines the sensor's response to an input. During a regular calibration using the load cell calibration machine, we check the sensor's zero offset and linearity by comparing the sensor output under reference weights and adjusting the sensor response to an ideal linear output. The load cell calibration equipment also check hysteresis, repeatability and temperature shift when customers request it for some critical force measurement applications.

For more information about calibration (calibrate measurement transducer), please refer to our Force Sensor Calibration FAQ Page.

If you have further questions about calibration terms and definitions, please refer to our Force Transducer Calibration Terms Glossary.

Want to know what calibration services we offer for your sensor and/or system?

How often should a button load cell be recalibrated?

As strain gauge load button are exposed to continuous usage, aging, output drift, overload and improper handling, FUTEK highly recommends a yearly recalibration interval. Frequent recalibration helps confirm whether the sensor maintained its accuracy over time and provides a load button calibration certificate to show that the sensor still meets specifications.

However, when the sensor is used in critical applications and harsh environments, button load cells may require even more frequent calibrations. Please consult with our Technical Support team, who will help you evaluate the most economical calibration service interval for your force sensor.

Want to learn more about Strain Gage Load Cell? Visit the "How a Load Cell works" page!

Due for recalibration?

Because our products are used in critical applications that require exact specifications, we have created a recalibration program that continuously supports our customer's needs for verification and alignment. We also offer recalibration services to customers who have purchased test and measurement products from the following manufacturers:

- Honeywell/Sensotec/Lebow

- Interfaceforce

- Omega

- Transducer Techniques

- HBM

- Himmelstein

- Strainsert

- See a complete list of Non-FUTEK sensors serviced by our Calibration Lab

Contact us to recalibrate your load button

What is system calibration (load button + amplifier/instrument)?

A system calibration provides the signature of the performance of the load button and instrument together ("calibration curve") and ensures that the combination of the results meets specifications. A force measurement system usually encompasses the sensor, instrument or signal conditioner, cabling, and connectors. Full system calibration ensures that the whole system is performing accurately as expected.

Check out below a video on the "Benefits of System Calibration":

Choosing complete system calibration allows you to start using your load measurement solution out of the box. A system calibration creates a plug & play solution where all connectors, cables, and instrument settings are taken care of.

As an A2LA-certified calibration lab, FUTEK offers full system calibration for sensors with digital displays, digital load cell amplifiers, and/or USB solutions, and uses calibration procedures in compliance with ISO 17025 standards. FUTEK's certification includes accreditation to ANSI/NCSL Z540-1.

Want to learn more about recalibration for your load cell, torque, or multi-axis force sensor?

What are the different types of load button calibration procedures?

One-point calibration is the simplest type of calibration and it is recommended for applications that only require accurate measurement at a single load. If the load button sensor is known to be linear, repeatable, and has the correct slope over the desired measurement range, a one-point calibration can be applied to adjust the zero offset error (zero balance).

A one-point load sensor calibration also helps to verify "output drift" in order to correct any deterioration in sensor performance over time.

A two-point calibration is a little more intricate and more precise than a one-point calibration. In a two-point calibration, the sensor offset is adjusted at two different output values, resulting in a reasonably accurate straight line across the entire force measurement scale. It is typically recommended that the two points used are zero and the full scale (rated output).

Load cell and torque sensors are known to be reasonably linear over the measurement range (or rated output), thus a two-point calibration is often recommended, given that a two-point calibration essentially re-scales the output by correcting both the slope (load cell sensitivity) and offset (zero balance) errors.

With the new zero offset and slope (load cell sensitivity), one can determine the linear equation that characterizes the sensor output (Vout=Sensitivity*Load + Zero_Offset).

Some critical applications require a high degree of accuracy over a very specific measurement range of the force sensor. In these cases, a five-point button load cell calibration services and curve fitting are required to characterize the calibration curve and achieve measurement output over the specified output range.

Normally, a five-point calibration is performed by taking the output at 0%, 20%, 40% 60%, 80%, 100% of the required measurement range:

- 0%: Zero offset adjustment (or zero balance);

- 20%, 40%, 60%, 80%: Linearity adjustments;

- 100%: Span or slope adjustment (sensitivity).

In the five-point sensor calibration process, the output readings are taken in the upscale and downscale values to determine the repeatability and hysteresis of the force measurement system (sensor + signal conditioner).

As most of the load buttons are paired with a readout display or signal conditioner, the instrumentation should always be hooked up with the sensor and be calibrated together as a system. That said, consider for example a 50 lbs LSB205 Miniature S-beam Load cell paired with an IAA200 4-20mA Current output amplifier and a 10ft long cable. When requested by the customer, the five-point output readings would be taken when the sensor is subjected to loads of 0 (no load), 10 lbs, 20 lbs, 30 lbs, 40 lbs and 50 lbs upward scale and downward scale.

| % of full scale | Applied Load (lbs.) | Amplifier Output (mA) |

|---|---|---|

| 0% - No Load | No Load | 4 mA |

| 20% | 10 lbs | 7.2 mA |

| 40% | 20 lbs | 10.4 mA |

| 60% | 30 lbs | 13.6 mA |

| 80% | 40 lbs | 16.8 mA |

| 100% - Full Scale | 50 lbs | 20 mA |

| 80% | 40 lbs | 16.8 mA |

| 60% | 30 lbs | 13.6 mA |

| 40% | 20 lbs | 10.4 mA |

| 20% | 10 lbs | 7.2 mA |

| 0% - No Load | No Load | 4 mA |

Depending on the application requirements, this procedure is repeated twice or multiple times. The difference in the outputs is utilized to calculate the non-repeatability (or repeatability) and linearity (accuracy).

Ready to calibrate your load cell, torque sensor or multi-axis force sensor?

Contact us to recalibrate your sensor!

An important concept regarding force transducers is load cell sensitivity and accuracy. Force Sensor accuracy can be defined as the smallest amount of force that can be applied to the sensor body required to cause a linear and repeatable variation in the voltage output. The higher the load cell accuracy, the better, as it can consistently capture very sensible force variations. In applications like high-precision factory automation, surgical robotics, and aerospace, load cell linearity is paramount in order to accurately feed the PLC or DAQ control system with accurate force measurement. Some of our Universal Pancake Load Cells present Nonlinearity of ±0.1% (of Rated Output) and Nonrepeatability of ±0.05% RO.