Multi-Axis Sensors

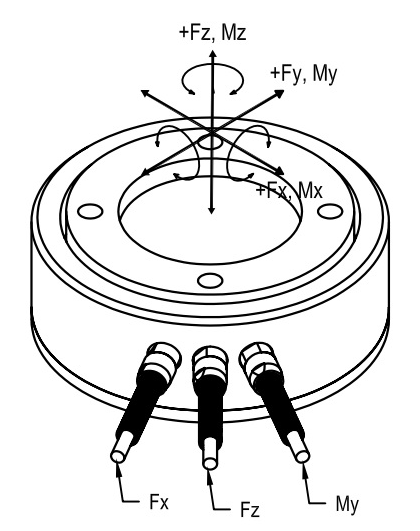

A Multi Axis Sensor is a force-torque transducer that measures up to 6 different forces (Fx, Fy, Fz) and torque (Mx, My, Mz), in 3 spatial directions and converts it into an electrical output signal. Multi Axis Sensors are also known as Multi-component transducers or force-torque sensors (i.e.: 2 axis force sensor, 3 axis force sensor, 6 axis sensor, 6 axis load cell, 6 DoF load cell).

Multi Axis Torque Sensors manufactured in the US by FUTEK Advanced Sensor Technology, a leading manufacturer producing a vast selection of Multi-axis load cells, utilizing one of the most advanced technologies in the Sensor Industry: Metal foil strain gauge technology.

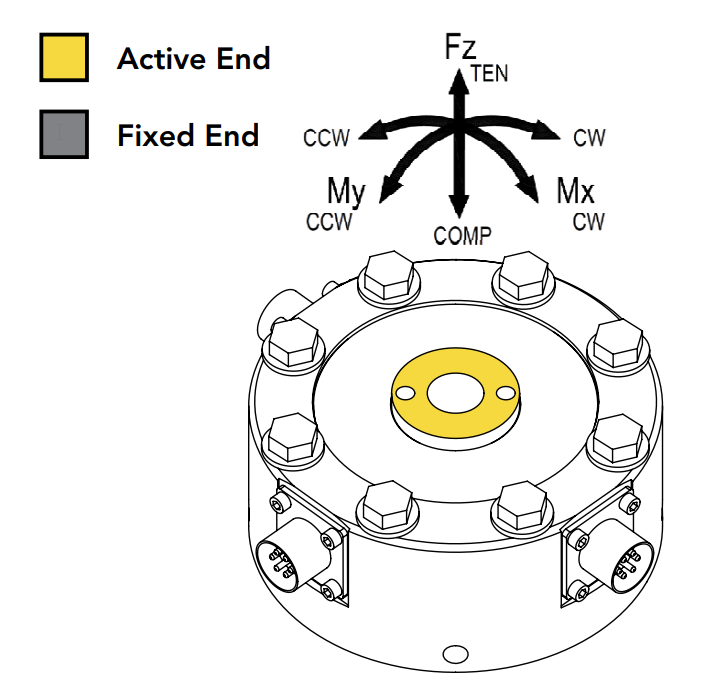

A Multi-Component Sensor (also commonly known as force torque sensor or multi-component load cell) designed to measure in all spatial directions: forces in tension and compression (±Fx, ±Fy, and ±Fz) as well as torques or moments in clockwise and counterclockwise (±Mx, ±My or ±Mz).

These special force-torque sensors are equipped with multiple strain gage bridges that accurately measure the forces and torques applied in one direction with little or no cross-talk interference from force or moments applied in other directions.

In applications where multiple force and torque vectors must be measured simultaneously in x, y and z-directions, multi axis sensors are the preferable choices. Due to its compact design, multicomponent transducers save up a lot of space in the assembly and installation work time when compared to the alternate solution of installing multiple single axis load cells and/or torque sensors.

Multi-Axis load cell is designed to independently measure force and torque in each of its axis or channels. However, based on the physical effect of Poisson forces, there will be expansion or contraction of the flexure material in directions perpendicular to the direction of applied loading. So, when a load or torque is applied in one direction only, there is also a minimum output signal in the other axis due to the transverse sensitivity of the sensor.

Crosstalk levels are part of the technical specs of multi-axis torque sensors. FUTEK sensors normally range in 2-4% of the output. The good news is that, during the 6 DoF load cell design phase (or two axis load cell), crosstalk interdependencies among forces and torques crosstalk can be compensated mathematically.

FUTEK’s multi-component sensors (not LVDT displacement sensors) can be used in many applications where a load or torque vector must be described in terms of x, y and z positional coordinates (Fx, Fy, Fz and Mx, My, Mz).

- 2-Axis Load Cell (Fx, Fy): The MBA400 Biaxial Load Arm is designed to measure forces in both Fx and Fy directions (tension and compression);

- 2-Axis Torque and Thrust Biaxial Sensor (Fz, Mz): The MBA500 Torque and Thrust Sensor is designed to measure both load (Fz) and reaction torque (Mz) directions;

- 3-Axis Low Profile Thrust and Moment Load Cell (Fz, Mx, My): The MTA500 & MTA505 3 DoF Force Sensors are designed to measure tension and compression forces in Fz directions as well as reaction torque moments in Mx and My, clockwise and counterclockwise directions;

- 3-Axis Load cell (Fx, Fy, Fz): The MTA400 & MTA600 3 DoF Force Sensors are designed to measure tension and compression forces in Fx, Fy and Fz directions;

- Custom Multi Axis Sensor: Our team of engineers can also design custom multi axis load cell, including 6 axis load cell design (aka 6 dof force sensor), to meet your requirements and capacities. We also hold in our inventory several custom units, making them available for quick delivery. Similarly to our entire Multi-Component Weight Sensor product line, custom models are manufactured in USA and utilizes metal foil strain gauge technology.

For minituarized versions of load cell and force sensors, visit our miniature sensors overview page.

One of the proudest developments of FUTEK Engineering Team ingenuity is the Multi Axis force sensor specifically designed for the Mars Rover Curiosity mission. FUTEK, as a prominent multi axis load cell manufacturer, developed a tri-axial load cell cryogenic sensor to operate aboard the rover in Martian soil. The multi-axial load and torque sensor is responsible for the maneuvers of the robotic arm. As the arm moves, the tri-axial sensor provides feedback to the operating device identifying the levels of torsion and force applied. The necessity of this multi axis transducer is to alert the rover if over-exertion on the arm occurs.

For experimental fuels, aerospike and other experimental altitude compensating nozzles, ground testing is necessary to characterize their thrust curves and Isp in static testing conditions. To accomplish this an LCF series load cell is mated between the rocket engine and the Rocket Engine Thrust Test Stand.

Drilling torque and thrust force measurement is a potential application for multi axis sensors. Based on the drilling measurement data, operators and manufacturing engineers can optimize the process, prevent process failures, predict power drill or drill bit maintenance or replacement, and investigate the drilling process parameters, including cutting speed, feed rate, drill bit geometry, and composition, on the output product quality.

Crash tests employes several multi-axis transducers. Test dummies are instrumented with crash test sensors mounted onto the main body joints and limbs and a data acquisition system capable of recording velocity of impact, chest displacement, deceleration rates and high-frequency forces exerted onto the test dummy at various instances.

In humanoid robot sensors, precision, agility, and safety are paramount. Force and torque sensors are designed to enable delicate manipulations and robust movements.

Another common aerospace industry application for multi channel force sensors are wind tunnels. Wind tunnels are used in aerodynamic research to study the effects of air moving past solid objects referred to as models. A model is mounted onto a stationary 3 degree of freedom load cell, which provides force measurement of the pressure placed on the object (i.e. aircraft) at test. Tri-axial Load Cell (MTA400) paired with Instrumentation (IAA Series Amplifier & USB Solutions). A pressure sensor may be also required in this case.

Last but not least, one of our most important Tri-axial load cell application: monitor the pull force (thrust) and the directions of the Santa Claus flying reindeer during the Christmas Eve! 😊 At December 24, Santa Claus has a busy night delivering gifts to the 1.3 billion children in the world. To meet his delivery schedule, Santa relies on high precision GPS navigation and autopilot systems to minimize travel time. Load feedback is necessary to confirm rein inputs and monitor reindeer health (even magical flying reindeer can grow exhausted). To monitor the reindeer, their harnesses are tied to a pair of FUTEK MTA600 tri-axial load cells hooked to IAA Series Amplifier .

Fly By Wire control system processes inputs made by either the pilot or autopilot and automatically controls the flight control surface actuators. Multi-Axis Force and Torque fly by wire sensors are heavily utilized in the flight test environment to validate the control system design based on the flight control laws.

Got creative and want to learn more about applications of 6 Axis Force Sensor and other multi component force sensors? Visit our Multi-Axis Sensors Applications Page.