What is a Force Transducer? | FUTEK

Resources › What is a force transducer?

Our definition of a force transducer may be a bit different than those of other sensor manufacturers. At FUTEK, we define a force transducer as a load cell intended for embedded, OEM-style applications.

Our force transducers, just like our load cells, contain a full-bridge strain gauge configuration. However, the wiring is exposed on our force transducers, requiring careful handling and precautions while mounting the sensor into your desired application. The sensors themselves are very thin, containing the full-bridge and all associated wiring on a flat plate.

We currently produce one force transducer, our FFP350. It is a flat plate with an "Archimedean" style cutout in the center which behaves much like a spring. Strain gauges attached to the plate measure the force applied on the center, in both tension and compression. Its small size makes it ideal for placing in small spaces.

What is a Force Transducer?

By definition, force sensor is a type of transducer, specifically a force transducer. It converts an input mechanical force such as load, weight, tension, compression or pressure into another physical variable, in this case, into an electrical output signal that can be measured, converted and standardized. As the force applied to the force sensor increases, the electrical signal changes proportionally.

Transducers became an essential element in many industries from Automotive, High precision manufacturing, Aerospace & Defense, Industrial Automation, Medical & Pharmaceuticals and Robotics where reliable and high precision measurement is paramount. Most recently, with the advancements in Collaborative Robots (Cobots) and Surgical Robotics, many novel force measurement applications are emerging.

How does a Force Transducer work?

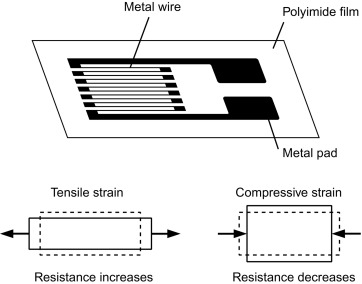

Firstly, we need to understand the underlying physics and material science behind the straing force measurement working principle, which is the strain gauge (sometimes referred to as Strain gage). Metal foil strain gage is a sensor whose electrical resistance varies with applied force. In other words, it converts (or transduces) force, pressure, tension, compression, torque, weight, etc… into a change in electrical resistance, which can then be measured.

Strain gauges are electrical conductors tightly attached to a film in a zigzag shape. When this film is pulled, it — and the conductors — stretches and elongates. When it is pushed, it is contracted and gets shorter. This change in shape causes the resistance in the electrical conductors to also change. The strain applied in the load cell can be determined based on this principle, as strain gauge resistance increases with applied strain and diminishes with contraction.

Structurally, a force sensor load cell is made of a metal body (also called flexure) to which foil strain gauges are bonded. The sensor body is usually made of aluminum or stainless steel, which gives the sensor two important characteristics: (1) provides the sturdiness to withstand high loads and (2) has the elasticity to minimally deform and return to its original shape when the force is removed.

When force (tension or compression) is applied, the metal body acts as a “spring” and is slightly deformed, and unless it is overloaded, it returns to its original shape. As the flexure deforms, the strain gage also changes its shape and consequently its electrical resistance, which creates a differential voltage variation through a Wheatstone Bridge circuit. Thus, the change in voltage is proportional to the physical force applied to the flexure, which can be calculated via the load cell circuit voltage output.

These strain gauges are arranged in what is called a Wheatstone Bridge Circuit (see animated diagram). This means that four strain gages are interconnected as a loop circuit (load cell circuit) and the measuring grid of the force being measured is aligned accordingly.

The strain gauge bridge amplifiers (or load cell signal conditioners) provide regulated excitation voltage to the load cell circuit and convert the mv/V output signal into another form of signal that is more useful to the user. The signal generated by the strain gage bridge is low strength signal and may not work with other components of the system, such as PLC, data acquisition modules (DAQ), computers, or microprocessors. Some application requires a local signal readout, also known as load cell indicator. Thus, sensor signal conditioner functions include excitation voltage, noise filtering or attenuation, signal amplification, and output signal conversion.

Furthermore, the change in the amplifier voltage output is calibrated to be linearly proportional to the Newtonian force applied to the flexure, which can be calculated via the load cell circuit voltage equation.

An important concept regarding load cells is sensitivity and accuracy. Sensor accuracy can be defined as the smallest amount of force that can be applied to the sensor body required to cause a linear and repeatable variation in the voltage output. The higher the load cell accuracy, the better, as it can consistently capture very sensible force variations. In applications like high precision factory automation, surgical robotics, aerospace, load cell linearity is paramount in order to accurately feed the PLC or DAQ control system with the accurate measurement. Some of our Universal Pancake Load Cells presents Nonlinearity of ±0.1% (of Rated Output) and Nonrepeatability of ±0.05% RO.

What are the advantages of strain gage-based force transducers?

Metal foil strain gauge force transducers are the most common technology, given its high accuracy, long term reliability, variety of shapes and sensor geometry and cost-effectiveness when compared to other measurement technologies. Also, strain gage sensors are less affected by temperature variations.

- The highest accuracy which may conform to many standards from Surgical Robotics to Aerospace;

- Robust Construction made of either high strength Stainless steel or Aluminum;

- Maintain high performance at the longest possible work life even at the most rigorous conditions. Some load cell designs can go up to billions of fully reversed cycles (lifespan).

- A plethora of geometries and customized shapes, as well as mounting options for ANY scale ANY-where.

- A full gamut of selections with capacities ranging from 10 grams to 100,000 pounds.

What are the types of strain gage-based force transducers?

Although there several technologies to measuring force, we will focus on the most common type of load cell: metal foil strain gauge. Within the types of force transducers, there are a variety of body shapes and geometries, each one catering to distinct applications. Get to know them if you want to buy load cell:

- In-Line Load Cell – Most commonly referred to as in-line load cell or a canister-style (or column) force sensor with male threads. This style of force sensor can be used in both tension and compression loading applications. In-line sensors offer high accuracy and high stiffness with minimal mounting clearance needed. They are great for endurance, and press applications.

- Load Button – These force transducers have a single flat, raised surface (aka a button) where the compressive force is applied. What’s impressive about load buttons is their low-profile design. As small as they are, they are known for their robustness and are used in fatigue applications. Load Buttons provide exceptional performance in high-frequency applications such as drop ball test.

- S-Beam Load Cell – With other names including Z-Beam or S-Type load transducers, the S-Beam force sensor is a tension and compression sensors with female threads for mounting. Sporting high accuracy and a thin beam load cell, compact profile, this force sensor type is great for in-line processing and automated control feedback applications. S Beam Load cells can also be used as a non contact flow sensor in fluid flow measurement applications or in wire crimp pull tester machines.

- Thru-Hole Load Cell – Also known as donut load cell or washer load cell, thru-hole load cell traditionally have a smooth non-threaded inner diameter used to measure compressive loads that require a rod to pass through its center. One of the primary uses of this sensor type is to measure bolt clamping force.

- Pancake Load Cells – Pancake, canister-style, or universal load cells have a central threaded hole for measuring loads in either tension or compression. These sensors are used in applications needing high endurance, high fatigue life, or high-capacity in-line measurements, such as tablet compression force, aircraft structural testing or automotive seat testing applications. They are also highly resistant to off-axis loading.

- Rod-End Load Cell – This load transducer type offers one male thread and one female thread for mounting. The male and female thread combination is well suited in applications where you need to adapt a force sensor into an existing fixture.

- Single Point Load Cell - Side mounted load cell with a single point design that are specifically made for OEM applications that require high precision or high volume production. These strain gauged based force sensors measure tension and compression and are also known as compact parallelogram sensors, or single point load cell. Side mount load cells such as the LSM300 model are a recommended OEM weight measurement solution for automatic bottle filling machines. LRF400 is an enclosed low capacity design suitable for applications such as high precision milligram scale for medication.

- Bending Beam Load Cell - The LBB200 Bending Beam Load Cell offers a slim design making it ideal for OEM applications. Utilized in Compression, the Bending Beam Load Cells can be used to measure force, surface pressure and displacement for OEM Applications. While FUTEK's average load cells and force sensors price range is about ~$600, LBB200 is a third of the price. LBB200 low cost load cell is an ideal fit for cost-sensitive applications that benefit from simple, accurate, and reliable strain-gauge-based force measurement sensors.

How to choose a force transducer for your application?

We understand that choosing the right load transducer is a daunting task, as there is no real industry standard on how you go about selecting one. There are also some challenges you may encounter, including finding the compatible amplifier or signal conditioner or requiring a custom product that would increase the product’s delivery time.

To help you select your sensor, FUTEK developed an easy to follow, 5-Steps guide. Here is a glimpse to help you narrow down your choices. Check out our “Important Considerations in Selecting a force measurement sensor” complete guide for further information.

- Step 1: Understand your application and what you are measuring. A Load sensor is different from pressure sensor, torque sensor, or force torque sensor and they are designed to measure tension and compression loads.

- Step 2: Define the sensor mounting characteristics and its assembly. Do you have static load or is it a dynamic type? Define the mounting type. How will you be mounting this Force Sensor?

- Step 3: Define your minimum and maximum capacity requirements. Be sure to select the capacity over the maximum operating load and determine all extraneous load (side loads or off-center loads) and moments prior to selecting the capacity.

- Step 4: Define your size and geometry requirements (width, weight, height, length, etc) and mechanical performance requirements (output, nonlinearity, hysteresis, creep, bridge resistance, resolution, frequency response etc.) Other characteristics to consider include submersible (waterproof), cryogenic, high temperature, multiple or redundant bridges, and TEDS IEEE1451.4.

- Step 5: Define the type of output your application requires. Transducer circuits outputs voltage in mV/V. So, if your PLC or DAQ requires analog output, digital output or serial communication, you will certainly need a load cell amplifier or signal conditioner. Make sure to select the right amplifier as well as calibrate the entire measurement system (load transducer + signal conditioner). This turnkey solution translates into more compatibility and accuracy of the entire force measurement system.

For more details on our 5-Steps Guide, please visit our “How to choose a Force Measurement Sensor” for complete guidelines.