FUTEK offices will be closed on Monday, May 27th, in observance of Memorial Day.

Resources › What is a load cell? What does a load cell do?

What is a load cell?

How do you get a weight scale to give an accurate measurement of an 18-wheeler truck? What kind of instrument would you use to measure the bite force of a great white shark? These questions may seem like they apply to two very different situations, but, oddly enough, they have the same answer: by using a load cell.

What is a loadcell sensor? A load cell, also known as a load or force transducer, is a sensor that measures applied forces. Load cells are capable of measuring both tension (force required to pull something) and compression (force required to push something). In order to measure these forces, the sensor creates an electrical output that changes depending on the amount of resistance being applied.

Force sensors are very commonplace and are incorporated into objects people use every day such as self-checkout systems at the grocery stores, or bathroom scales. But they are also used in more high-tech settings. Engineers rely on these sensors to measure rocket engine thrust, the grip force of a robotic claw, and a variety of other advanced applications.

Different types of load cells:

There are three main types of load cells that use a different way of converting the force applied into an electrical output: pneumatic load cells, hydraulic load cells, and strain gauge load cells. Within these three main categories are sub-categories. We will focus on the most common type of load cell: strain gauge.

Strain gauge load cells are a type of resistive load cell, which includes Single Point Load cells, Button Load Cells, S-Beam Load Cells, Miniature Load Cells, Thru-Hole Load Cells, and Pancake Load Cells. Each subsection is ideal for a different type of test. An S-beam load cell would be used in applications where tensile and compressive forces are tested. A button load cell is suitable for compression only application while a thru-hole load cell would be the best choice for measuring loads that need to be threaded (ex. bolt clamping force).

Here's an overview of the most common strain gauge load cell types:

In-Line Load Cells – Most commonly referred to as an in-line load cell or a canister-style load cell with male threads. This style of sensor can be used in both tension and compression loading applications. In-line load cells offer high accuracy and high stiffness with minimal mounting clearance needed. They are great for endurance, off-center, and press applications.

Load Button Load Cells – These load cells have a single flat, raised surface (aka a button) where the compressive force is applied. What's impressive about load buttons is their low profile design. As small as they are, they are known for their robustness and are used in fatigue applications.

S-Beam Load Cells – With other names including Z-Beam or S-Type load cells, the S-Beam is a tension and compression sensor with female threads for mounting. Sporting high accuracy and a thin, compact profile, this load cell type is great for in-line processing and automated control feedback applications.

Thru-Hole Load Cells – Also known as donut load cell or washer load cell, these sensors traditionally have a smooth inner diameter used to measure compressive loads that require a rod to pass through its center. One of the primary uses of this sensor type is to measure bolt clamping force.

Pancake Load Cells – Pancake, canister-style, or universal load cells have a central threaded hole for measuring loads in either tension or compression. These load cells are used in applications needing high endurance, high fatigue life, or high-capacity in-line measurements. They are also highly resistant to off-axis loading.

Rod-End Load Cells – This load cell type offers one male thread and one female thread for mounting. The male and female thread combination is well suited in applications where you need to adapt a sensor into an existing fixture.

Single Point Load Cell - Side-mounted load cell with a single point design that is specifically made for OEM applications that require high precision or high volume production. Also known as shear beam load cells, these strain gauged-based force sensors measure tension and compression and are also known as compact parallelogram sensors or single point load cell. LRF400 is an enclosed low-capacity design suitable for applications such as high-precision milligram scale for medication.

How do load cells work?

Load cells typically produce an electrical signal in millivolts that varies proportionally with the load that is being applied. However, some load cells produce digital signals or amplified analog signals that vary either in voltage, i.e. +/-10V, or current, i.e. 4-20 mA.

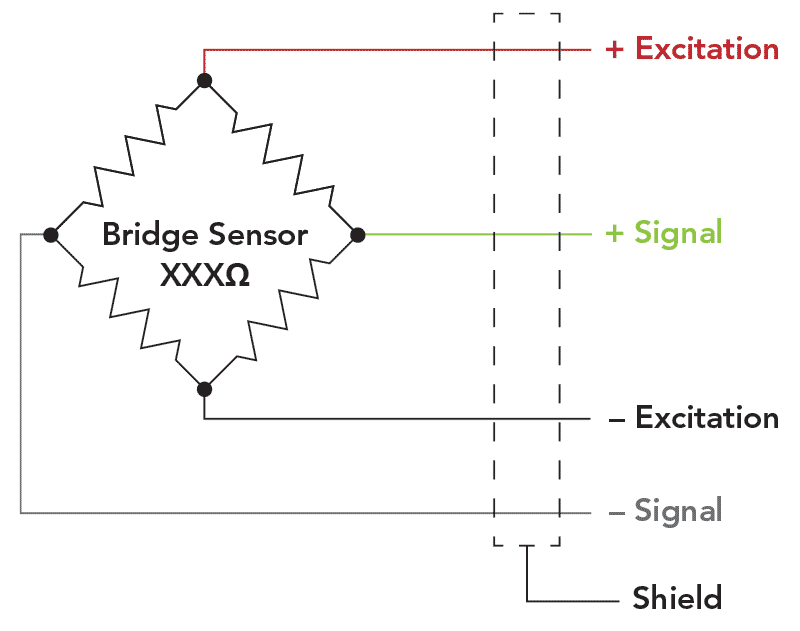

So how do strain gauge load cells produce the electrical signal? Inside, strain gauges are bonded to key structural points, and wired together into a full Wheatstone bridge. Inside each gauge is a series of fine wires. As a force is applied to the load cell, the strain gauges undergo inelastic deformation causing a change in length in the gauges' fine wires. This changes the resistance of the strain gauges, producing a measurable change in voltage across the bridge. This voltage change is a linear relationship with respect to load.

How do you read the sensor's signal?

In order to read the output signal of a load cell and see the results from your testing, you can use an analog amplifier to a DAQ, PLC, or other analog display. Another option is connecting the sensor to a digital instrument such as a USB which then translates the data to a computer. Any one of these can be integrated to work with load cells, torque sensors, and pressure sensors, while providing highly accurate readings.