Shear Beam Load Cell

What is a Beam Load cell and how does it work?

A beam load cell is one of the most common categories of load cell, which is commonly found within the weighing industry and scale applications. It is also also known as single point load cell, bending beam load cell, platform load cell, or cantilever load cells. It is arguably the most common type of load cell in use today.

The working principle of beam load cells is quite simple: they act as cantilevers that slightly bend when subjected to load or force. Usually, beam load cells are mounted with one end fixed and the other end free, behaving like a “diving board”.

The bending beam load cell category offers slim designs with excellent endurance making them ideal for OEM applications. One clear advantage is the model's miniature size, making it ideal for tight environments.

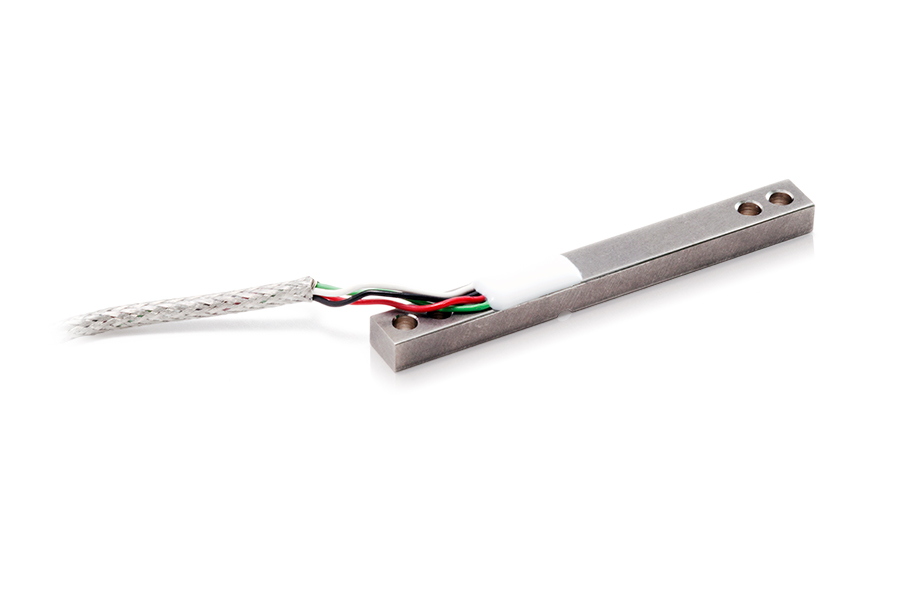

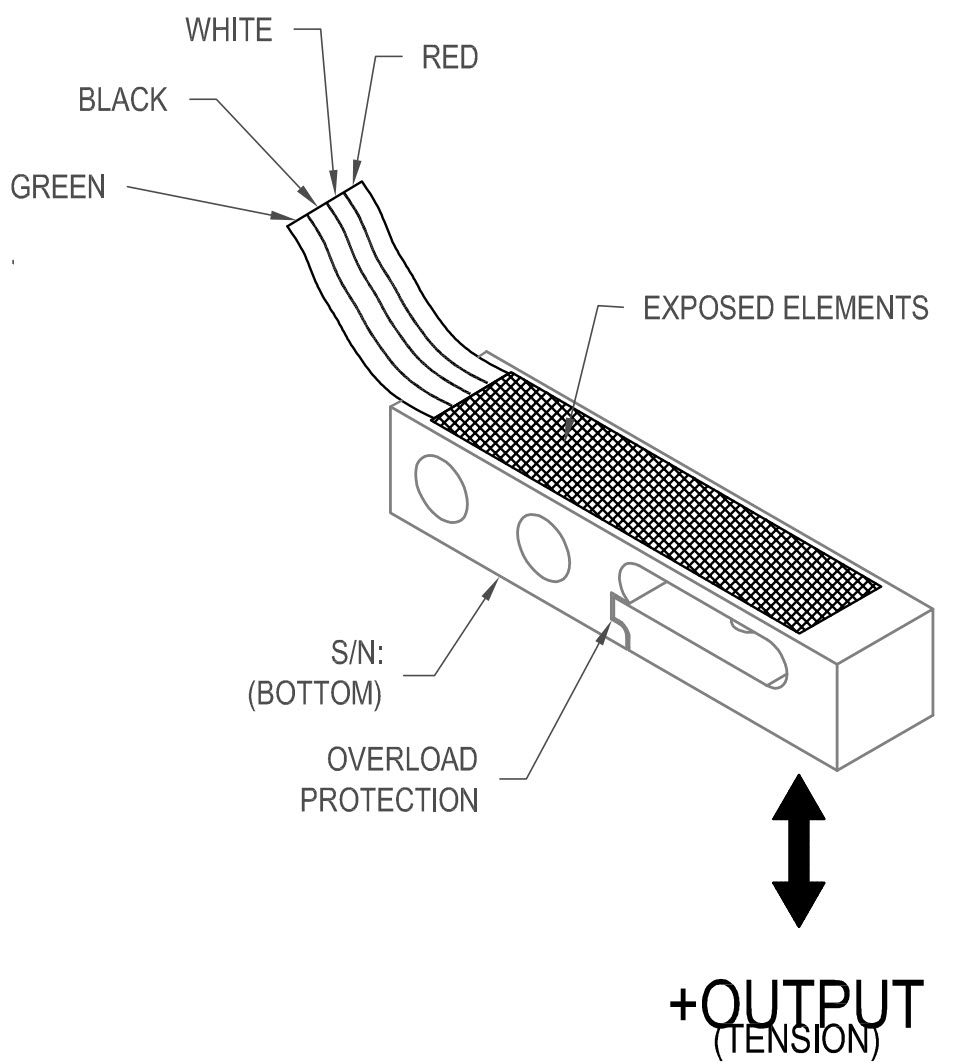

FUTEK's LBB200 Bending Beam Load Cell (or Cantilever Beam Load Cell) has a miniature package of 0.18” height, 2.56” length and 0.28” width. Utilized in Compression, the Bending Beam Load Cells can be used to measure force, surface pressure, and displacement for OEM Applications. The LBB200 is offered in stainless steel and has a shielded PVC cable.

As a part of FUTEK’s original product line, the LBB200 Bending Beam Load Cell can be modified or customized to meet your requirements. The standard models are in our stock making them available for 24-hour shipping. Similar to our entire Load Cell product line, this model is manufactured in the US and uses metal foil strain gauge technology. Overload Protection is also available on select models.

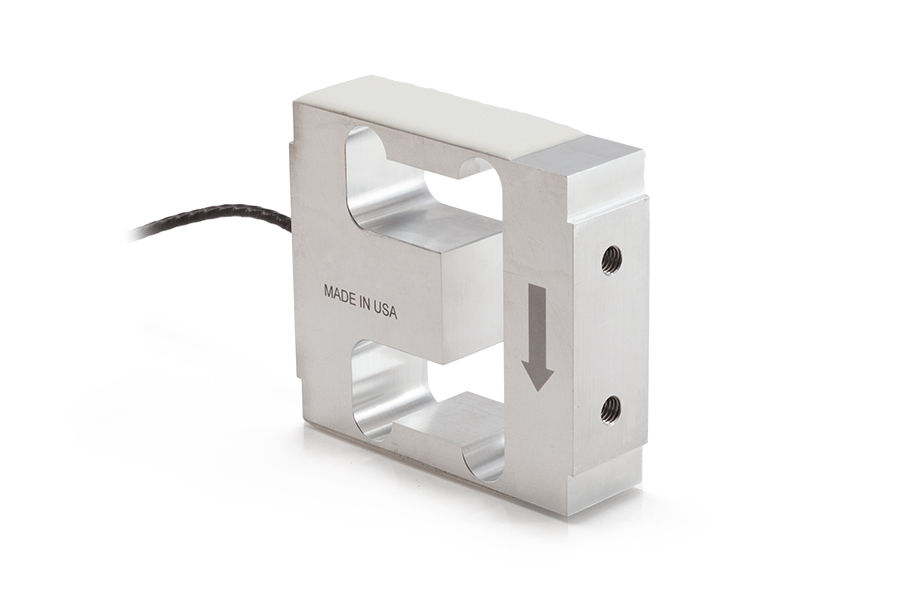

What is a Shear Beam Load Cell?

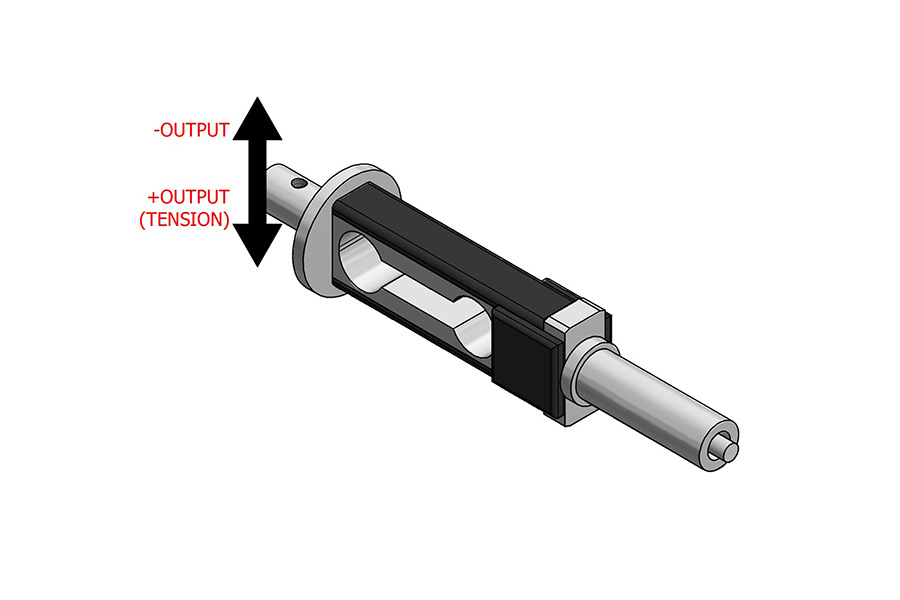

Beam load cells can be split into two subcategories, depending on the way they measure force or weight. Bending beam cells measure the amount of bending strain on flexure while shear beam cells measure the shear strain on the beam.

Geometrically, the bending beam flexure looks very similar to the shear beam load cell, but their working principle differs. A bending beam load cell has the strain gauge laminated on the top of the beam surface, while a shear beam load cell has a pocket is machined in each side of the beam, leaving a relatively thin vertical web in the center of the top flanges. This gives the load cell a cross-sectional appearance similar to steel structural I-beams, and as with them, most of the shear strain is concentrated in this thinner section. Strain gauges are laminated on the whing web surface to detect the strain.

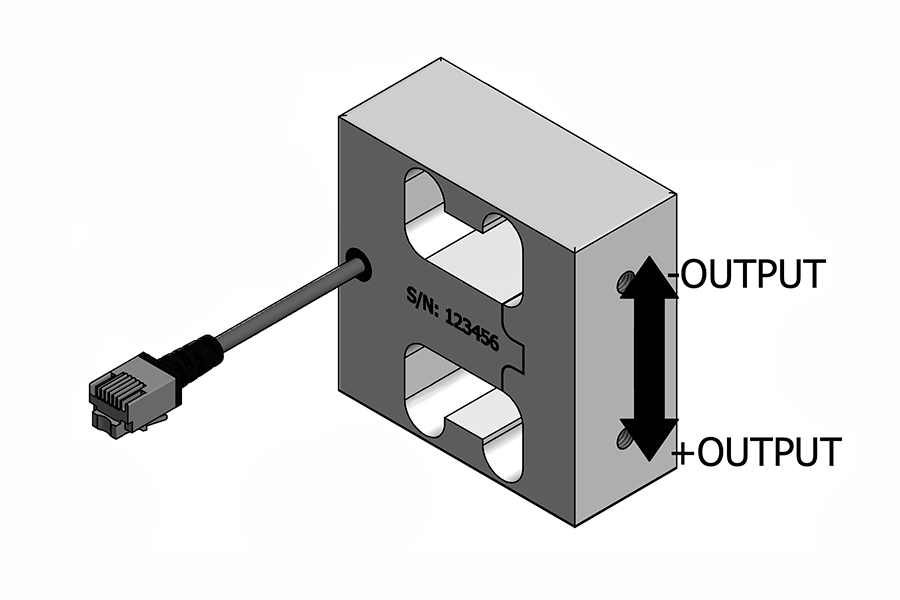

Why Side Mount Load cells are a better alternative to Shear Beam Load Cells?

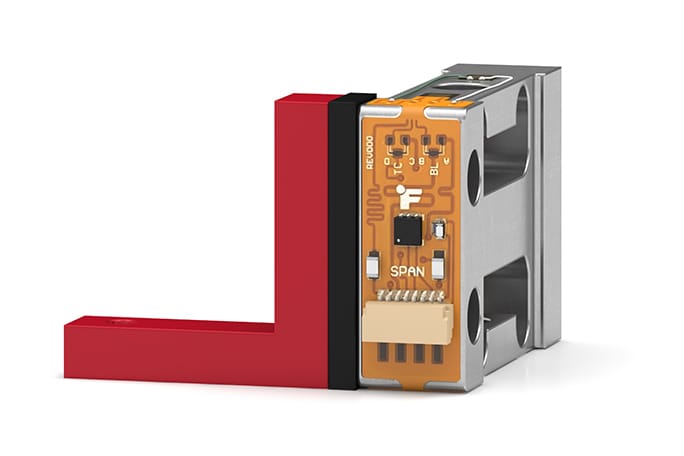

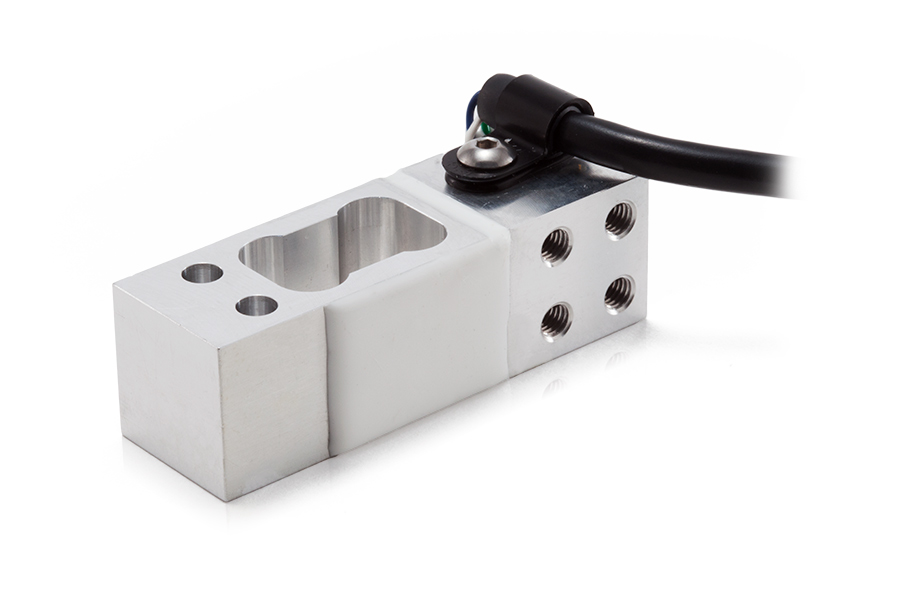

The advantage of a side mount load cell design over that of a shear beam load cell is that the former has higher precision and can better withstand off-center loading. Additionally, side mount load cells are designed for high volume OEM applications and are offered in a wide range of capacities from 0.25 lbs to 200 lbs in the same form fit function.

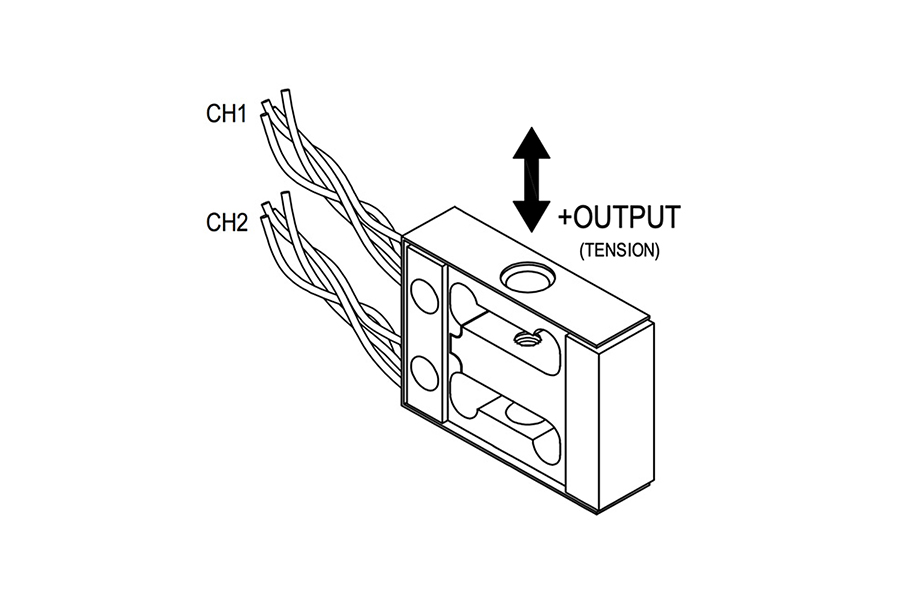

FUTEK’s LSM Series is comprised of side-mounted load cells with a single point design that are specifically made for OEM applications that require high precision or high volume production. These strain gauge-based force sensors measure tension and compression and are also known as parallelogram sensors, single point load cells, or beam load cells.

The lightweight design and easy side mounting make these load cells particularly easy to assemble into the housing of OEM applications. Built-in overload protection allows these durable force sensors to withstand over 10 times the rated capacity that could occur during installation and operation.

Single point load cells are unique in that they can accept an off-center load (aka extraneous loads or off-axis loads), which means that they can accurately measure forces and loads that are not well centralized in the measuring point, therefore, allowing them to be highly precise in industrial applications.

The models, which are available in aluminum and stainless steel, can be modified or customized to meet your requirements. Most standard capacities are in stock in our inventory, making them available for 24-hour shipping.

LSM305: Higher Accuracy, up to 100x Overload Protection & TEDS for easier integration

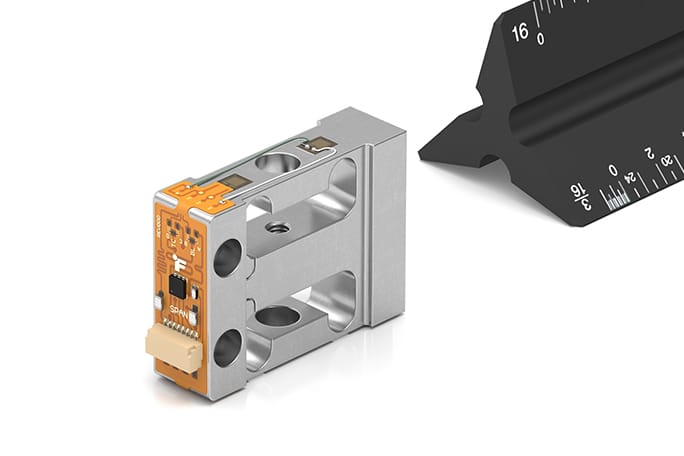

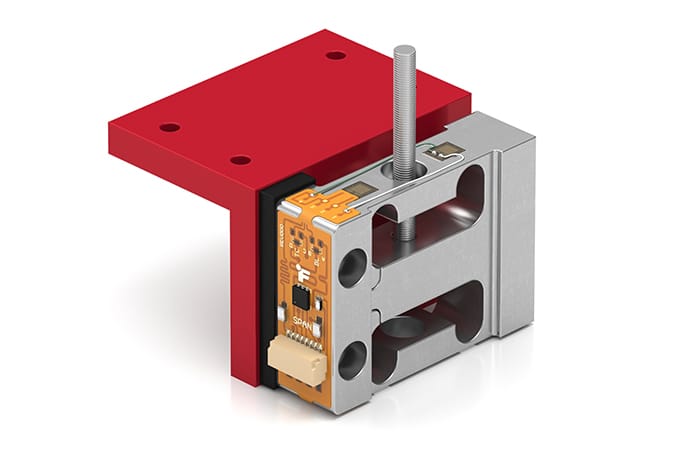

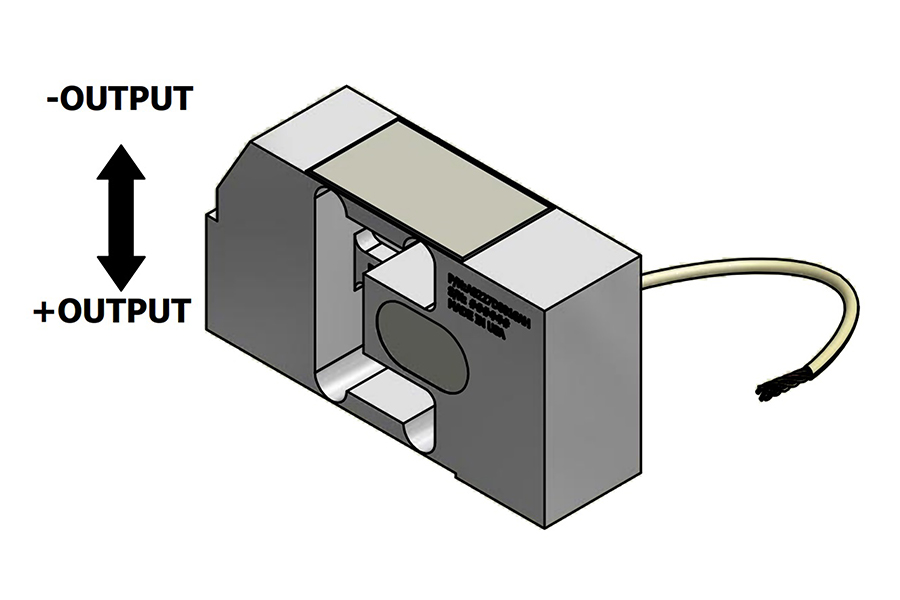

The LSM305 High Accuracy OEM Single Point Load Cell also known as the Single Point Force Sensor offers an impressive lightweight and compact design with an easy side mounting feature making it ideal for embedded and OEM.

Utilized in both tension and compression, the precision load cell's miniature size (1.80”length, 0.50” width, 1.40” height) makes it well suited for any tight spaces.

Features highlights:

- Intended for high volume OEM embedded applications

- Easily integrates into OEM applications

- Built-in robust overload protection

- Exceptional nonlinearity and nonrepeatability

Additional design features include:

- Built-in overload protection in tension and compression provides the unit over 10 times the capacity that could take place during installation or operation.

- Integrated IEEE1451.4 TEDs make setup simple and greatly reduce setup errors. Connects directly to electronics and auto-scales to FUTEK instruments and signal conditioners.

- RTD Pt1000 temperature sensor enables support for real-time temperature compensation, ensuring accuracy in different environments.

- Detachable 8 Pin Receptacle allows for quick production assembly and flexibility with cable lengths and routings.

The LSM30X is one of our most accurate load cells whose strong performance is supported by its integrated overload stop. The unique design protects the sensor from damage during accidental overload and decreases the risk of mechanical breakage and yield. LSM30X sensors operate flawlessly through more than 100 million cycles.

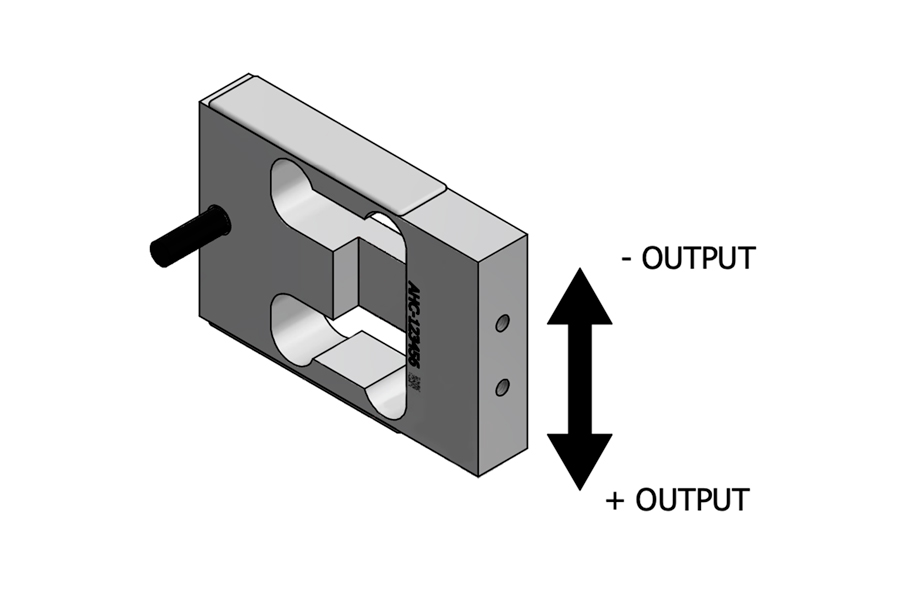

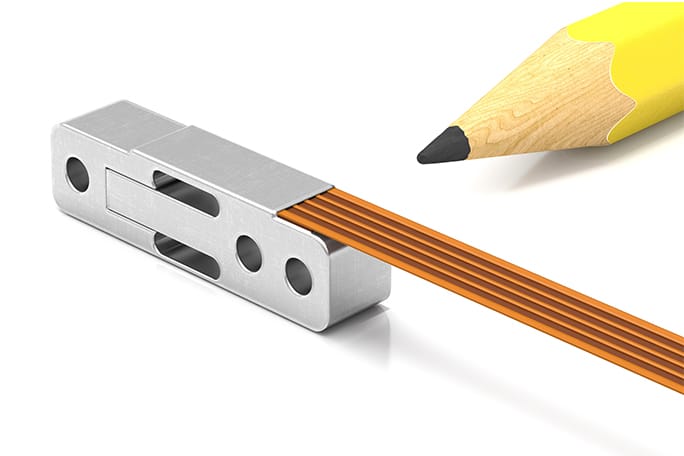

LSM100 Micro Parallelogram Load Cell

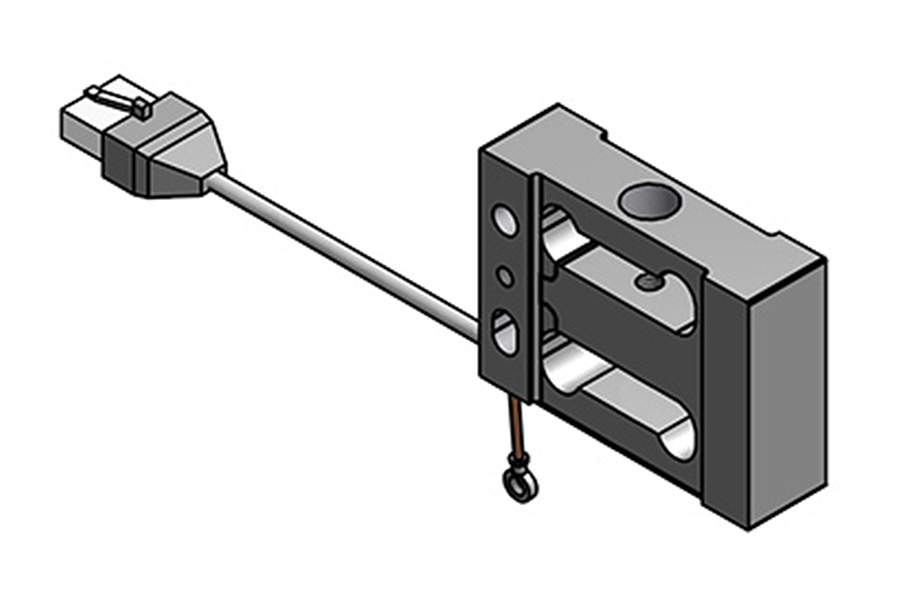

One of the smallest sensors in the FUTEK catalog, the miniature wall mount sensor LSM100 is a micro parallelogram load cell that stands out because of its extremely low profile, greater output, low power consumption, and overload protection without compromising performance.

The unit can be used in both tension and compression modes. It has a low height of 0.25” (6.4mm), a load capacity of 450 grams, and a built-in 10X overload protection. The delicate strain gauge instrumentation is placed only on the top side, and there are two mounting provisions at the non-loading end.

LSM100 is designed for high volume continuous usage and can be easily integrated into OEM applications. Typical applications include medical weighing and industrial measurements.

The sensor itself weighs only 2.3 grams; and delivers accurate readings with a maximum of 10V input. Its 3 mV/V output coupled with a 1000 ohm bridge can offer 50% greater resolution.

Custom Side Mount Load Cells for Critical Applications

FUTEK offers custom versions of our high accuracy OEM Single Point Load Cells that are ideal for mission-critical applications such as medical and aerospace.

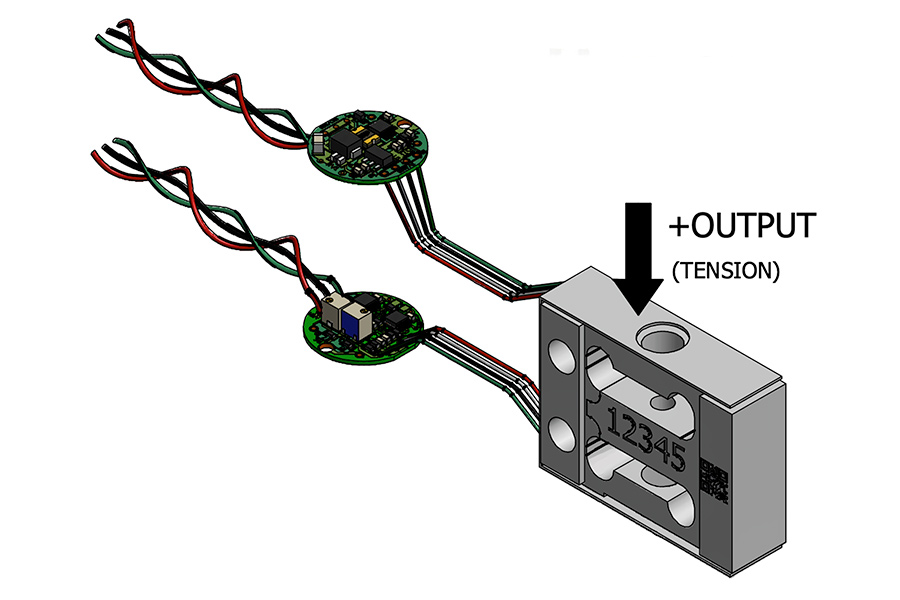

For example, the QLA337 is a Custom Dual/Redundant Bridge Load Cell that has been designed to optimize the performance of medical applications. If your application requires voltage output, you may consider QLA376 Parallelogram Dual Bridge Load Cell with inline amplifier. QLA376 eliminates the necessity of any additional signal amplifier hooked up to the sensor as it provides 8 VDC rated output.

Custom Load Cell and OEM Solutions

FUTEK offers a large selection of off-the-shelf force-torque sensors that are very well suitable for crash testing applications. FUTEK's in-house multidisciplinary engineering teams also develop cutting-edge custom sensors with unique geometries, performance capabilities, and outputs to fit your application requirements.

All our products are designed and manufactured in-house, using US-sourced materials. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.