Understanding Conveyor Belt Weighing Systems

Industries that manage bulk materials—such as metals and mining, agriculture, food processing, construction, recycling, and power generation—rely on conveyor belt weighing systems to gain real-time insights into material flow. These systems play a critical role in improving inventory accuracy, reducing waste, optimizing throughput, and ensuring compliance with quality and regulatory standards.

How Are Load Cells Used in Conveyor Belt Weighing Systems?

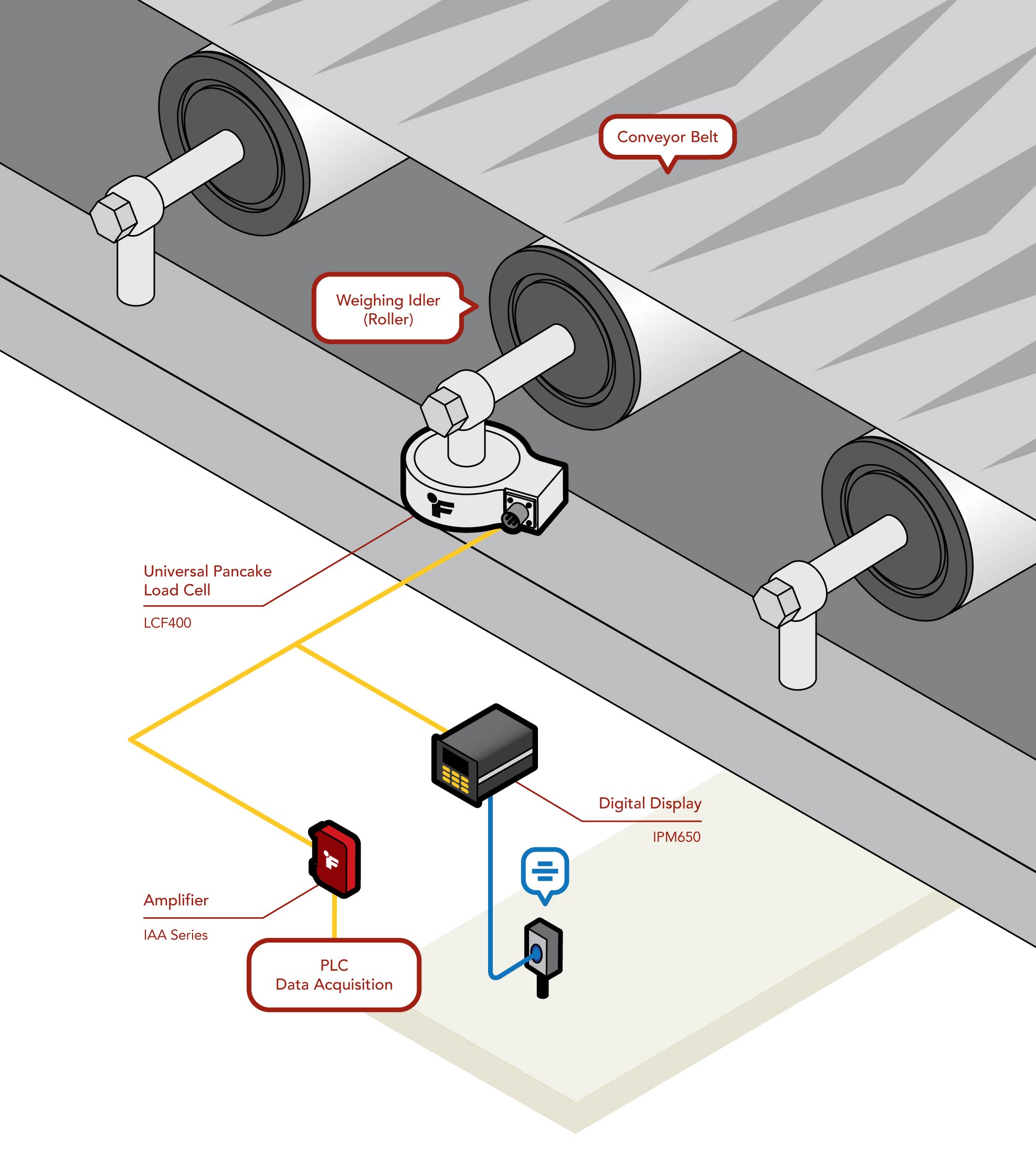

Conveyor belt load cells are the key component in a belt scale system, responsible for converting the material weight into accurate load measurements. A well-designed load cell is engineered with high-stiffness flexures to minimize deflection, resist off-axis and extraneous loads, and deliver highly repeatable force measurements. Since vibration and motion are common in conveyor systems—and can introduce side or torsional forces that distort readings—a conveyor belt load cell must be designed to reject these unwanted inputs and isolate the true vertical force (Fz) from the moving material.

Choosing the Right Load Cell for Conveyor Belt Weighing Systems

Selecting the right load cell is critical to ensuring accurate, reliable, and long-lasting performance in conveyor belt weighing systems. LCF400 Universal Pancake Load Cell is a robust and versatile sensor choice for OEMs and system integrators designing belt scale solutions. Below are key features that make the LCF400 a fit for this application:

- ✅ Wide Load Capacity Range and Overload Protection: The LCF400 is available in capacities from 250 lbs to 5,000 lbs, making it suitable for a broad range of conveyor belt systems—from light to heavy-duty. It offers a 150% safe overload rating, delivering extra protection in demanding industrial settings where mechanical shock and weight surges are common.

- ✅ High Accuracy and Dynamic Response: With a nonlinearity of ±0.1% of Rated Output, the LCF400 ensures consistent, repeatable measurements. Its high natural frequency, ranging from 2,600 Hz to 7,700 Hz depending on capacity, allows for rapid dynamic response.

- ✅ Durability in Harsh Environments: The sensor’s body is machined from aerospace-grade 17-4 PH stainless steel, providing superior mechanical strength and corrosion resistance. Though the standard unit is rated IP64, FUTEK can offer custom solutions (IP67 or IP69K) for added protection in wet or dusty environments such as food processing or agriculture.

- ✅ Resistance to Extraneous Loads: Conveyor systems often introduce unwanted forces—side loading, or vibration—that can skew readings. The LCF400 features a multi-beam internal structure engineered to reject off-axis and extraneous loads, ensuring that only the true vertical force (Fz) from the moving material is captured.

Seamless Integration with Industrial Systems

Selecting the right load cell is only part of the equation—seamless integration with industrial control systems is essential for real-time monitoring, data acquisition, and process automation. FUTEK offers a versatile portfolio of signal conditioners, displays, and digital interfaces that ensure accurate data transmission and easy integration into existing infrastructure. Beyond the IAA Series and IPM650, FUTEK also offers a broad range of signal conditioning and data output solutions, including sensors with embedded digital electronics (UART, SPI) for full integration into modern automation architectures.

Custom Load Cell Solutions for Weighing Systems

While FUTEK does not manufacture complete belt scale or checkweighing systems, we specialize in providing custom-engineered load cells that seamlessly integrate into these platforms. Our solutions are developed in close collaboration with OEMs and system integrators, ensuring every sensor meets the specific performance, dimensional, and environmental demands of the application.

Through our Engineer-to-Order (EOT) process, FUTEK supports projects from concept design through volume manufacturing. This multidisciplinary approach combines mechanical design, electronics, embedded firmware, and system-level integration to deliver turnkey sensor solutions.

How it Works

Products in Use

Contact Us

All FUTEK application illustrations are strictly conceptual.

Please Contact Us with questions.

Please Contact Us with questions.

Understanding Conveyor Belt Weighing Systems

Industries that manage bulk materials—such as metals and mining, agriculture, food processing, construction, recycling, and power generation—rely on conveyor belt weighing systems to gain real-time insights into material flow. These systems play a critical role in improving inventory accuracy, reducing waste, optimizing throughput, and ensuring compliance with quality and regulatory standards.

How Are Load Cells Used in Conveyor Belt Weighing Systems?

Conveyor belt load cells are the key component in a belt scale system, responsible for converting the material weight into accurate load measurements. A well-designed load cell is engineered with high-stiffness flexures to minimize deflection, resist off-axis and extraneous loads, and deliver highly repeatable force measurements. Since vibration and motion are common in conveyor systems—and can introduce side or torsional forces that distort readings—a conveyor belt load cell must be designed to reject these unwanted inputs and isolate the true vertical force (Fz) from the moving material.

Choosing the Right Load Cell for Conveyor Belt Weighing Systems

Selecting the right load cell is critical to ensuring accurate, reliable, and long-lasting performance in conveyor belt weighing systems. LCF400 Universal Pancake Load Cell is a robust and versatile sensor choice for OEMs and system integrators designing belt scale solutions. Below are key features that make the LCF400 a fit for this application:

- ✅ Wide Load Capacity Range and Overload Protection: The LCF400 is available in capacities from 250 lbs to 5,000 lbs, making it suitable for a broad range of conveyor belt systems—from light to heavy-duty. It offers a 150% safe overload rating, delivering extra protection in demanding industrial settings where mechanical shock and weight surges are common.

- ✅ High Accuracy and Dynamic Response: With a nonlinearity of ±0.1% of Rated Output, the LCF400 ensures consistent, repeatable measurements. Its high natural frequency, ranging from 2,600 Hz to 7,700 Hz depending on capacity, allows for rapid dynamic response.

- ✅ Durability in Harsh Environments: The sensor’s body is machined from aerospace-grade 17-4 PH stainless steel, providing superior mechanical strength and corrosion resistance. Though the standard unit is rated IP64, FUTEK can offer custom solutions (IP67 or IP69K) for added protection in wet or dusty environments such as food processing or agriculture.

- ✅ Resistance to Extraneous Loads: Conveyor systems often introduce unwanted forces—side loading, or vibration—that can skew readings. The LCF400 features a multi-beam internal structure engineered to reject off-axis and extraneous loads, ensuring that only the true vertical force (Fz) from the moving material is captured.

Seamless Integration with Industrial Systems

Selecting the right load cell is only part of the equation—seamless integration with industrial control systems is essential for real-time monitoring, data acquisition, and process automation. FUTEK offers a versatile portfolio of signal conditioners, displays, and digital interfaces that ensure accurate data transmission and easy integration into existing infrastructure. Beyond the IAA Series and IPM650, FUTEK also offers a broad range of signal conditioning and data output solutions, including sensors with embedded digital electronics (UART, SPI) for full integration into modern automation architectures.

Custom Load Cell Solutions for Weighing Systems

While FUTEK does not manufacture complete belt scale or checkweighing systems, we specialize in providing custom-engineered load cells that seamlessly integrate into these platforms. Our solutions are developed in close collaboration with OEMs and system integrators, ensuring every sensor meets the specific performance, dimensional, and environmental demands of the application.

Through our Engineer-to-Order (EOT) process, FUTEK supports projects from concept design through volume manufacturing. This multidisciplinary approach combines mechanical design, electronics, embedded firmware, and system-level integration to deliver turnkey sensor solutions.