Overview|Technical Documents|Specifications|Related Instruments|Related Accessories|Applications|Alternative Models

Parallelogram Load Cell with TEDS and PT-1000 RTD

LSM305 , 10 lb , Parallelogram Load Cell with TEDS and PT1000 RTD , RoHS Compliant , Material - 2024-T4 , #10-32-Thread , Overload Protection , 8 position 0.039" (1.00mm) JST Connector

In Stock

Listed price is in U.S. currency and subject to verification along with availability

Description

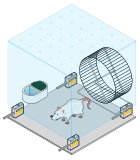

Single Point load cells are are a very popular choice given their high accuracy and high reliability. They are also known as “platform load cells” or "parallelogram load cells" as this is their most common application. Platform Load Cells are typically used in low-capacity compact OEM force measurement systems.

Single point load cells are unique in that they can accept an off-center load (aka extraneous loads or off-axis loads), which means that it can accurately measure forces and loads that are not well centralized in the measuring point, therefore, allowing them to be highly precise in industrial applications.

The LSM305 High Accuracy OEM Single Point Load Cell also known as the Single Point Force Sensor offers an impressive lightweight and compact design with an easy side mounting feature making it ideal for embedded and OEM.

Utilized in both Tension and Compression, the Precision Load Cell has a length of 1.86”, width of 0.50” and with a height of 1.3” it is well suited for any tight spaces.

Additional design features include:

- A built-in overload protection in tension and compression provides the unit over 10 times the capacity that could take place during installation or operation.

- Integrated IEEE1451.4 TEDs make setup simple and greatly reduce setup errors. Connects directly to electronics and auto-scales to FUTEK instruments and signal conditioners.

- PT1000 temperature sensor enables support for real-time temperature compensation, ensuring accuracy in different environments.

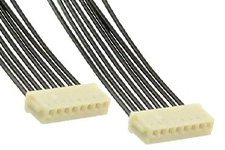

- Detachable 8 Pin Receptacle allows for quick production assembly and flexibility with cable lengths and routings.

Features

- Intended for high volume OEM embedded applications

- Easily integrates into OEM applications

- Built-in robust overload protection

- Exceptional Nonlinearity and Nonrepeatability

- Integrated IEEE1451.4 TEDs Auto-Recognition

- On-Board PT1000 RTD Temperature Sensor

Technical Documents

Specifications

| CHANNEL | MIN | TYP | MAX | UNIT | |

|---|---|---|---|---|---|

Calibration Excitation | 1 | 10 | Vdc | ||

Excitation | 1 | 1 | 18 | Vdc | |

Input Resistance | 1 | 1400 | Ohms nom. | ||

Insulation Resistance | 1 | 500 | Mohms @ 50 Vdc | ||

Safe Overload | 1 | 250 | lbs | ||

Capacity | 1 | 10 | lbs | ||

Hysteresis | 1 | -0.02 | 0.02 | % of R.O. | |

Nonlinearity | 1 | -0.02 | 0.02 | % of R.O. | |

Nonrepeatability | 1 | -0.02 | 0.02 | % of R.O. | |

Output Resistance | 1 | 1000 | Ohms nom. | ||

Rated Output | 1 | 2 | mV/V nom. | ||

Compensated Temperature | 1 | 60 | 160 | F | |

Operating Temperature | 1 | -13 | 185 | F | |

Temperature Shift Span | 1 | -0.005 | 0.005 | % of Load/F | |

Temperature Shift Zero | 1 | -0.005 | 0.005 | % of R.O./F |

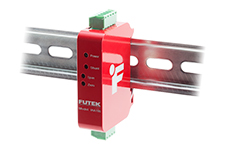

Related Instruments

Related Accessories

Alternative Models

LTH350 , 2000 lb , Through Hole Donut/Washer Load Cell , 1/2" [12.7 mm] ID , IP67 Rated , Material - 17-4 PH S.S. , RoHS Compliant , 4 Pin Micro Receptacle

All other trademarks, service marks and logos used in this website are the property of their respective owners.

© 1998–2025 FUTEK Advanced Sensor Technology, Inc. All rights reserved.

+

+

19 Morgan, Irvine,

CA 92618 USA

CA 92618 USA

All other trademarks, service marks and logos used in this website are the property of their respective owners.

© 1998–2025 FUTEK Advanced Sensor Technology, Inc. All rights reserved.