Load Cell, Force Sensors & Transducers - Applications | FUTEK

Topics

Announcements

FUTEK Education Program

180 Universities and Counting

FUTEK's Educational Program has served the needs of over 180 universities and looks forward to continue working with the educational community. Whether you've come to check out the product list or use our Support Tools, FUTEK strives to provide the information and services necessary to best help you navigate the Sensor world.

Announcements

To say that we take on unique applications would be an understatement. When the good folks at the Pankey Institute For Continuing Dental Education contacted us with their custom application, FUTEK welcomed the challenge and was more than eager to find a solution. For us, the challenge was simple. Kinda.

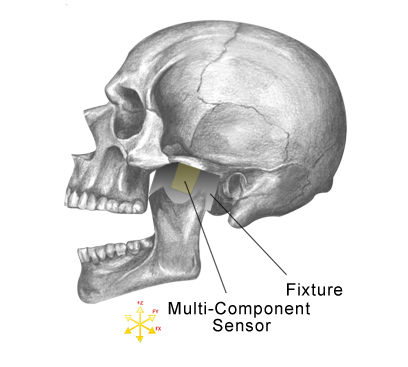

They required a sensor that would measure the multiple forces applied to the condyles of the mandible (jaw line). The sensor would help the Pankey Institute students practice by measuring and controlling the forces they applied to the mandible. This would eventually benefit their future patients that suffered from Temporomandibular Joint Disorder (TMJ) enabling them to exercise the best way to properly relocate the jaw. Prior to this, existing technology was limited and training was done through subjective feedback of instructors. Although FUTEK had supported medical related applications in the past, this was a new challenge; one that forced our Engineers to think outside the box.

Skull shown with Multi Component Sensor. The positioning of the sensor reads measurements applied to jaw.

When FUTEK Engineers are faced with extreme circumstances such as the “Jaw Breaker” Sensor requirements, one of the key components in the process is the interaction between us and the client. Sometimes the opportunity to meet the client face to face is provided making interaction much more convenient. Most of the time though, such opportunities are not available. This leads to countless hours which are spent discussing design methods, size limitations, specifications, and of course finding a solution while sticking to the designated budget. Although this process can be a long and demanding one, FUTEK overcomes all obstacles by gaining their clients trust in our expertise.

When our Engineers approached the Jaw Breaker Sensor, they didn’t limit themselves to the traditional designs of a Sensor/Transducer. The final design resulted in a shape that was different from any other sensor we had manufactured. Cultivating such an open approach did not occur over night. This transpired over several meetings and concepts which FUTEK came up with in order to meet needs of the application. Companies often overlook this factor and select a Sensor Manufacturer based on price. Having a creative approach is a critical element when reaching a solution can be difficult. The unique aspect of the “Jaw Breaker” sensor is the measurements in 4 different directions (see spec sheet). FUTEK Engineers came up with a small cylinder which they designed, developed, and produced by working directly with the Institute. FUTEK’s first goal when taking on custom projects, involving extreme cases such as this, is to listen to their customer and welcome as much information as possible. In doing so our Engineers strive to meet their customer’s needs, in this case, endurance, durability, ease of installation and durability of the sensor itself while being able to measure the multiple directions of forces being applied. No job is too big or too small for FUTEK, give us what you got and see what we can come up with.

FUTEK Precision Machining is a full service machine shop specializing in high quality machining, design, prototyping and production. Serving the Aerospace, Medical, Military, and Marine industries we are able to provide unparalleled expertise from design input to fabrication. With over 20 years of experience machining a vast line of complex and high quality sensor flexures with related accessories we are highly qualified to support your projects. Whether you are running a prototype or a full production run, our unified team is able provide you with high quality solution.

FUTEK’s Miniature Load Cells and Sub Miniature Load Cell series provide diverse solutions for Aerospace, Medical, Automotive, and Manufacturing industries. These products offer solutions for applications in both Tension and Compression. Even with the miniature design an impressive capacity range of of 10 gram up to 20,000 lbs is available.

Product News

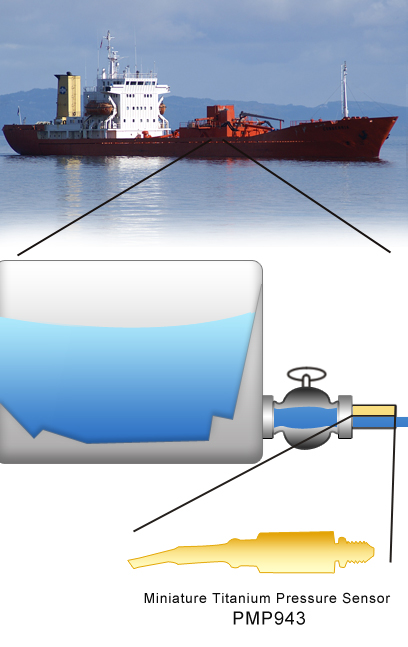

FUTEK Advanced Sensor Technology, Inc. (FUTEK) has just added the PMP943 Miniature Pressure Sensor to their USB Sensor Solution Line. The new module with USB output eliminates the need for an analog amplifier, power supply, and display equipment making usage that much easier. The plug and play gives you power to monitor the output of the sensor and enjoy measurement that is less affected by noise, temperature variation or power supply requirement. The USB integration also includes FUTEK’s USB Software which allows users to monitor the output of the Sensor in real time.

Update your Account information, click here.

All information provided by customer are confidential and FUTEK will not release any customer information to third parties.

FUTEK respects your right to privacy.

19 Morgan Irvine, CA 92618; Phone: (949) 465-0900; Fax: (949) 465-0905; www.futek.com

©1998-2009 FUTEK Advanced Sensor Technology, Inc. All rights reserved.