Strain Gauge Analog Amplifier with Current Output

Broad Compatibility, Precision You Can Trust

FUTEK's IAA200 Analog Amplifier with Current Output is FUTEK’s brand new general purpose amplifier solution for in-line amplification of any full bridge strain gauge type sensor with mV/V range output. The new model combines precision and ease of integration with a total error of 0.01% of full scale reading. The IAA200 features an aluminum housing with an integrated DIN clip designed for industrial environment applications.

The IAA200 is a high-precision analog amplifier designed for strain gauge-based sensors. It delivers enhanced signal conditioning with superior accuracy and rugged reliability where analog voltage solutions fall short.

This unit offers:

- Non-linearity improved to ±0.01% of FSR

- Noise performance enhanced to 15 μAp-p (Typ)

- Hot-swappable functionality for live system integration

- Built-in ESD, over-voltage, and over-current protection

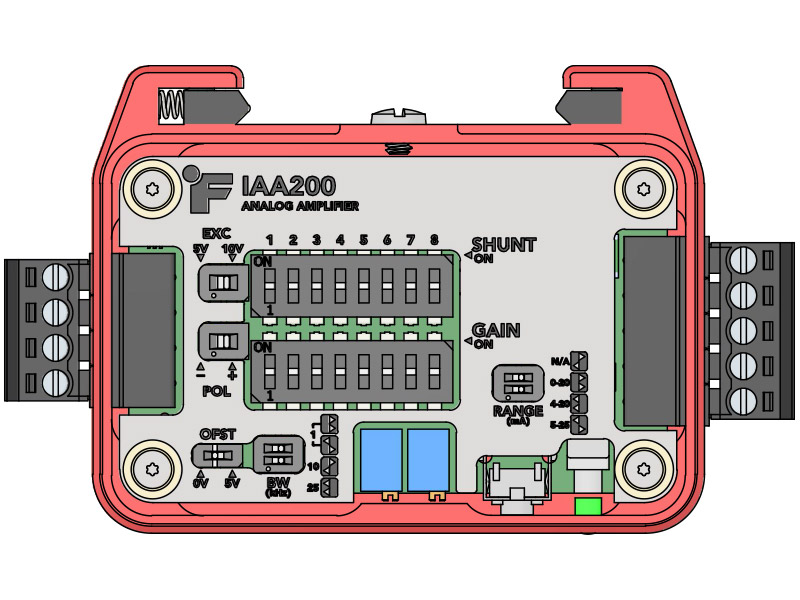

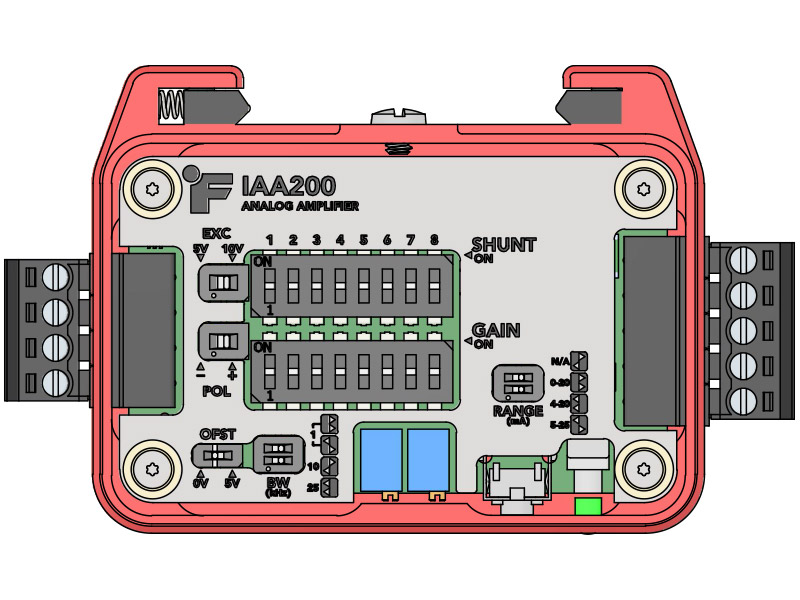

- 256 selectable gain combinations via DIP switches

The IAA200 supports 5 VDC and 10 VDC bridge excitation voltages, features a removable magnetic metal cover for EMI shielding, and includes a spring-loaded 35mm DIN clip for secure DIN rail mounting. Built to IPC-A-610 Class 3 standards, it meets aerospace and medical-grade quality requirements, ensuring stable and accurate amplification in demanding environments.

Flexible Gain and Output Configuration for Sensor Compatibility

Offering a variety of current output options, including 4–20 mA and 12 ±8 mA, the IAA200 is ideal for long-distance signal transmission. It provides improved noise immunity and minimizes signal degradation in electrically noisy industrial environments, while seamlessly integrating with a wide range of current-based data acquisition systems.

It features 256 selectable gain combinations via DIP switches, allowing users to adjust the amplifier gain to their specific sensor’s mV/V output and excitation voltage. The gain combinations, in conjunction with selectable bridge excitation voltages of 5 VDC or 10 VDC, enable compatibility with a wide range of strain gauge-based sensors.

For added flexibility, users have access to a Zero Shift and sensor polarity DIP switch. The Zero Shift DIP switch provides a selectable offset of 0 or midpoint (depending on current output configuration), while the sensor polarity switch enhances setup efficiency by allowing quick polarity adjustments without having to rewire.

Low Noise Performance

The refined design of the IAA200 significantly reduces current output noise levels, enhancing signal fidelity and overall system performance. This amplifier ensures precise and reliable continuous analog signal without compromising the performance of connected sensors. Additionally, the inclusion of an external chassis connection offers robust noise isolation, minimizing external interference and ensuring measurement accuracy in challenging environments.

With a non-linearity of ±0.01% of FSR, well beyond typical industry specifications, the IAA200 delivers accurate and repeatable sensor output, making it suitable for applications requiring tight tolerances or closed-loop control.

Hot-Swappable for Safe and Continuous Operation

The IAA200 comes with the ability to hot swap, acting both as a protection in the event the unit is plugged in with power on or as a feature required for unique applications where power cannot be turned off.

Built-In Protection for Reliable Operation

This strain gauge amplifier features robust on-board protection circuitry to safeguard against electrostatic discharge (ESD) and overcurrent/voltage events. This ensures more reliable connections and enhances the overall durability of the unit.

Selectable Shunt Calibration and Wide Supply Compatibility

The IAA200 provides 256 selectable shunt combinations configured via DIP switches. The selected shunt combination helps simulate specific load conditions on the load cell, enabling calibration, troubleshooting, or DAQ setup when applying an actual load is impractical. Shunt activation is controlled via the front pushbutton or a remote digital input (5–26 VDC) connected to pin 3 on the power side connector, allowing efficient and uninterrupted operation.

Additionally, the IAA200 supports a broad supply voltage range from 12.5 to 26 VDC, ensuring seamless compatibility with various power supplies in industrial settings.

Rugged Housing and Industrial-Grade Build Quality

Designed for durability in critical environments, the IAA200 features a metal magnetic cover that protects internal circuitry, enhances noise immunity, and provides partial EMI shielding, ideal for high-precision applications. The cover also helps prevent damage during installation and reduces ESD exposure. For secure and efficient mounting, the unit includes a spring-loaded 35mm DIN clip, ensuring firm attachment to DIN rails.

Assembled to IPC-A-610 Class 3 standards, the IAA200 meets aerospace and medical-grade quality requirements, delivering reliable performance in demanding industries.

Broad Compatibility, Precision You Can Trust

FUTEK's IAA200 Analog Amplifier with Current Output is FUTEK’s brand new general purpose amplifier solution for in-line amplification of any full bridge strain gauge type sensor with mV/V range output. The new model combines precision and ease of integration with a total error of 0.01% of full scale reading. The IAA200 features an aluminum housing with an integrated DIN clip designed for industrial environment applications.

The IAA200 is a high-precision analog amplifier designed for strain gauge-based sensors. It delivers enhanced signal conditioning with superior accuracy and rugged reliability where analog voltage solutions fall short.

This unit offers:

- Non-linearity improved to ±0.01% of FSR

- Noise performance enhanced to 15 μAp-p (Typ)

- Hot-swappable functionality for live system integration

- Built-in ESD, over-voltage, and over-current protection

- 256 selectable gain combinations via DIP switches

The IAA200 supports 5 VDC and 10 VDC bridge excitation voltages, features a removable magnetic metal cover for EMI shielding, and includes a spring-loaded 35mm DIN clip for secure DIN rail mounting. Built to IPC-A-610 Class 3 standards, it meets aerospace and medical-grade quality requirements, ensuring stable and accurate amplification in demanding environments.

Flexible Gain and Output Configuration for Sensor Compatibility

Offering a variety of current output options, including 4–20 mA and 12 ±8 mA, the IAA200 is ideal for long-distance signal transmission. It provides improved noise immunity and minimizes signal degradation in electrically noisy industrial environments, while seamlessly integrating with a wide range of current-based data acquisition systems.

It features 256 selectable gain combinations via DIP switches, allowing users to adjust the amplifier gain to their specific sensor’s mV/V output and excitation voltage. The gain combinations, in conjunction with selectable bridge excitation voltages of 5 VDC or 10 VDC, enable compatibility with a wide range of strain gauge-based sensors.

For added flexibility, users have access to a Zero Shift and sensor polarity DIP switch. The Zero Shift DIP switch provides a selectable offset of 0 or midpoint (depending on current output configuration), while the sensor polarity switch enhances setup efficiency by allowing quick polarity adjustments without having to rewire.

Low Noise Performance

The refined design of the IAA200 significantly reduces current output noise levels, enhancing signal fidelity and overall system performance. This amplifier ensures precise and reliable continuous analog signal without compromising the performance of connected sensors. Additionally, the inclusion of an external chassis connection offers robust noise isolation, minimizing external interference and ensuring measurement accuracy in challenging environments.

With a non-linearity of ±0.01% of FSR, well beyond typical industry specifications, the IAA200 delivers accurate and repeatable sensor output, making it suitable for applications requiring tight tolerances or closed-loop control.

Hot-Swappable for Safe and Continuous Operation

The IAA200 comes with the ability to hot swap, acting both as a protection in the event the unit is plugged in with power on or as a feature required for unique applications where power cannot be turned off.

Built-In Protection for Reliable Operation

This strain gauge amplifier features robust on-board protection circuitry to safeguard against electrostatic discharge (ESD) and overcurrent/voltage events. This ensures more reliable connections and enhances the overall durability of the unit.

Selectable Shunt Calibration and Wide Supply Compatibility

The IAA200 provides 256 selectable shunt combinations configured via DIP switches. The selected shunt combination helps simulate specific load conditions on the load cell, enabling calibration, troubleshooting, or DAQ setup when applying an actual load is impractical. Shunt activation is controlled via the front pushbutton or a remote digital input (5–26 VDC) connected to pin 3 on the power side connector, allowing efficient and uninterrupted operation.

Additionally, the IAA200 supports a broad supply voltage range from 12.5 to 26 VDC, ensuring seamless compatibility with various power supplies in industrial settings.

Rugged Housing and Industrial-Grade Build Quality

Designed for durability in critical environments, the IAA200 features a metal magnetic cover that protects internal circuitry, enhances noise immunity, and provides partial EMI shielding, ideal for high-precision applications. The cover also helps prevent damage during installation and reduces ESD exposure. For secure and efficient mounting, the unit includes a spring-loaded 35mm DIN clip, ensuring firm attachment to DIN rails.

Assembled to IPC-A-610 Class 3 standards, the IAA200 meets aerospace and medical-grade quality requirements, delivering reliable performance in demanding industries.