High Capacity Load Button with Threaded/Tapped Holes

Accurate, submersible and durable

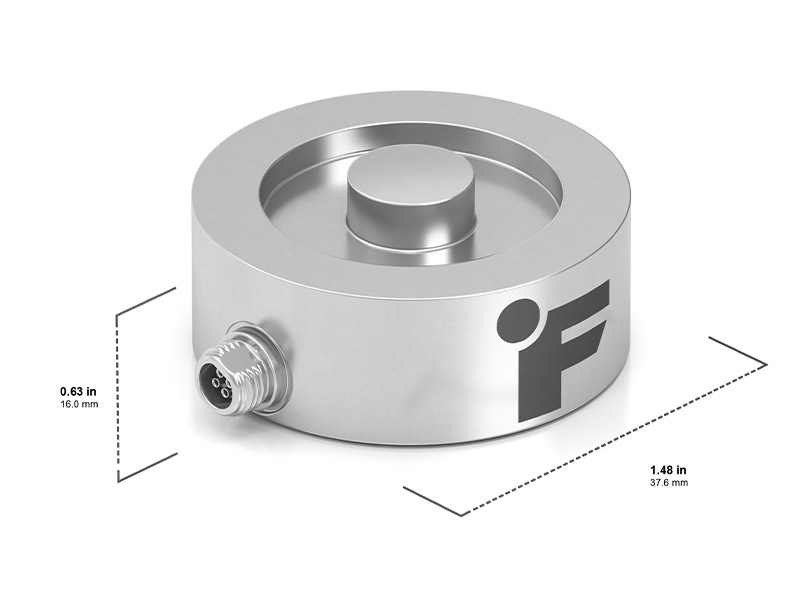

With a package that stands at 1.48in (37.6mm) in diameter and 0.63in (16.0mm) in height, the LLB450 Load Button Load Cell is an extraordinarily accurate miniature sensor that punches well above its size with a capacity range from 5000 and 10000lb (2268 and 4536kg). This diverse and durable sensor solution features three mounting holes built for press or inline compression applications, such as measuring loads on a turbine shaft or gauging forces on a CNC workpiece.

The LLB450 is now offered with an integrated connector that makes it fully IP67-rated for high water resistance and temporary submersibility. The connectorized 4-position micro receptacle allows you to easily remove the wire from the sensor like a plug from a socket. This new feature protects the sensor from cable damage, as you can easily replace a faulty wire. In addition, FUTEK can offer custom versions that are rated for vacuum/low outgassing, high or low operating temperatures, radiation environments, autoclavable, and high vibration/shock.

The LLB450 is also available in the original design, which features a cable connection with a 10-foot (3.048m) long 28 AWG 4 conductor Teflon cable.

Wide capacity range

LLB450 series offers button load cells in six capacity options that measure compressive loads from 5000 and 10000lb (2268 and 4536kg), a remarkable range for such a tiny package. Three threaded holes allows the part to be securely mounted from the bottom.

Plug in, plug out

The newer version of this series — including the entire 5000 and 10000lb capacity range — feature the 4-position micro receptacle. This gives the load cell greater flexibility and durability, as a damaged or cut cable can now easily be replaced, saving the user time and resources. It also simplifies the installation process, reducing installation time and maximizing up time.

Fast response rate

The LLB450 delivers a remarkably high natural frequency (starting above 30kHz) which provides a fast response time that benefits accuracy and cycle time reduction. The precision of the sensor is also augmented by its high stiffness, which leads to a very low deflection with some capacities as low as 0.003in (0.076mm).

Low power-consumption

With a 700 bridge resistance, the LLB450 consumes around 50% less current than a traditional load cell. This is especially valuable for any applications that are battery operated or are embedded in tight spaces where heat generation could become an issue.

Designed for precision

The spherical radius of the load button has been designed to maintain the highest possible level of accuracy. By minimizing contact with the loading provisions, the button’s spherical shape transfers the load evenly over the sensing area, compensating for potential misalignments.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, and corrosion resistance over a wide temperature range.

Robust construction

The seam-welded stainless steel body provides outstanding strength and corrosion resistance and provides enhanced protection against physical damage in addition to withstanding other harsh environmental conditions. A special heat treatment process has been applied to the flexure to improve durability, extending the life-cycle of the sensor.

Eliminating moisture

The robust assembly of the 4-position micro receptacle version eliminates moisture ingress through the connection location. With an IP67 rating, the product can withstand submersion in one meter of water for up to 30 minutes. This opens up more options for applications as it will allow outdoor usage in wet, rainy, or highly humid conditions.

Calibration included

The LLB450 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

Accurate, submersible and durable

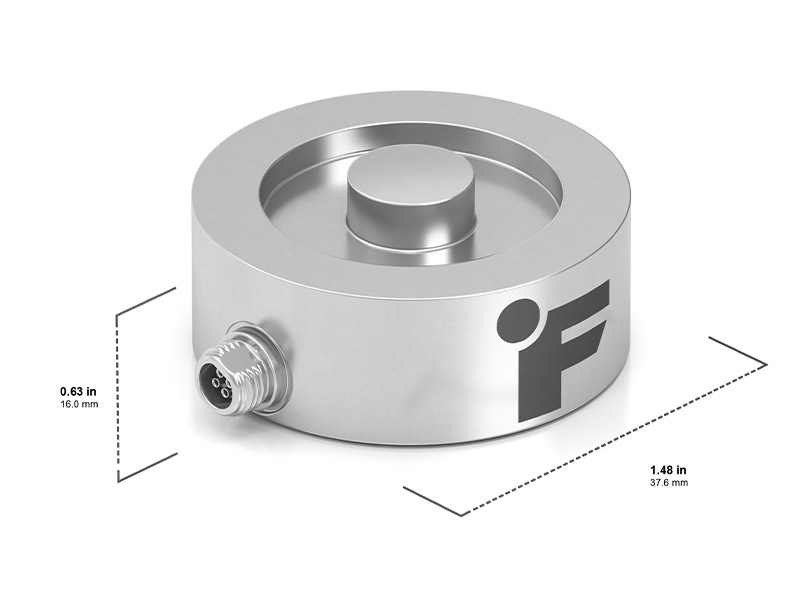

With a package that stands at 1.48in (37.6mm) in diameter and 0.63in (16.0mm) in height, the LLB450 Load Button Load Cell is an extraordinarily accurate miniature sensor that punches well above its size with a capacity range from 5000 and 10000lb (2268 and 4536kg). This diverse and durable sensor solution features three mounting holes built for press or inline compression applications, such as measuring loads on a turbine shaft or gauging forces on a CNC workpiece.

The LLB450 is now offered with an integrated connector that makes it fully IP67-rated for high water resistance and temporary submersibility. The connectorized 4-position micro receptacle allows you to easily remove the wire from the sensor like a plug from a socket. This new feature protects the sensor from cable damage, as you can easily replace a faulty wire. In addition, FUTEK can offer custom versions that are rated for vacuum/low outgassing, high or low operating temperatures, radiation environments, autoclavable, and high vibration/shock.

The LLB450 is also available in the original design, which features a cable connection with a 10-foot (3.048m) long 28 AWG 4 conductor Teflon cable.

Wide capacity range

LLB450 series offers button load cells in six capacity options that measure compressive loads from 5000 and 10000lb (2268 and 4536kg), a remarkable range for such a tiny package. Three threaded holes allows the part to be securely mounted from the bottom.

Plug in, plug out

The newer version of this series — including the entire 5000 and 10000lb capacity range — feature the 4-position micro receptacle. This gives the load cell greater flexibility and durability, as a damaged or cut cable can now easily be replaced, saving the user time and resources. It also simplifies the installation process, reducing installation time and maximizing up time.

Fast response rate

The LLB450 delivers a remarkably high natural frequency (starting above 30kHz) which provides a fast response time that benefits accuracy and cycle time reduction. The precision of the sensor is also augmented by its high stiffness, which leads to a very low deflection with some capacities as low as 0.003in (0.076mm).

Low power-consumption

With a 700 bridge resistance, the LLB450 consumes around 50% less current than a traditional load cell. This is especially valuable for any applications that are battery operated or are embedded in tight spaces where heat generation could become an issue.

Designed for precision

The spherical radius of the load button has been designed to maintain the highest possible level of accuracy. By minimizing contact with the loading provisions, the button’s spherical shape transfers the load evenly over the sensing area, compensating for potential misalignments.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, and corrosion resistance over a wide temperature range.

Robust construction

The seam-welded stainless steel body provides outstanding strength and corrosion resistance and provides enhanced protection against physical damage in addition to withstanding other harsh environmental conditions. A special heat treatment process has been applied to the flexure to improve durability, extending the life-cycle of the sensor.

Eliminating moisture

The robust assembly of the 4-position micro receptacle version eliminates moisture ingress through the connection location. With an IP67 rating, the product can withstand submersion in one meter of water for up to 30 minutes. This opens up more options for applications as it will allow outdoor usage in wet, rainy, or highly humid conditions.

Calibration included

The LLB450 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.