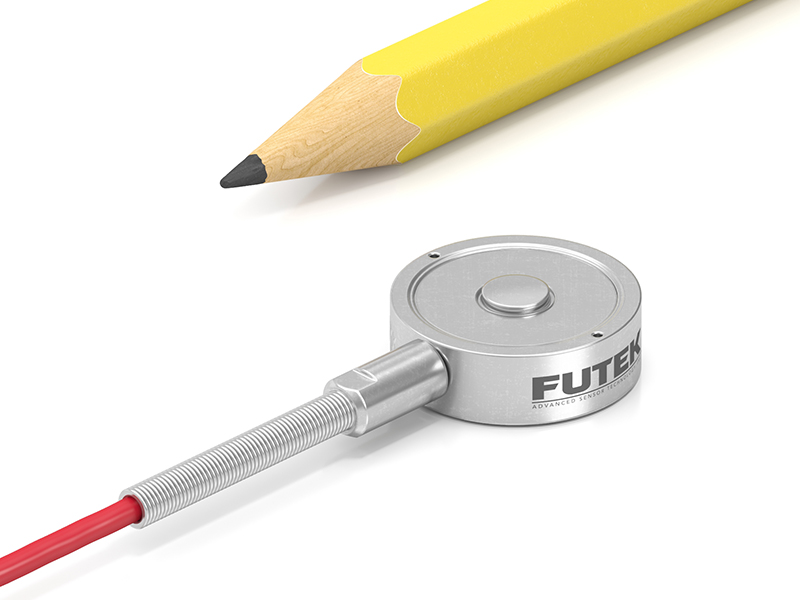

Miniature Load Button

Compact overachiever for mission critical applications

Model LLB300 is a Miniature Load Button built for Press, or Inline compression applications. The standard LLB300 Miniature Load Button model has a very robust construction available in 17-4 Stainless Steel, with a 0.74” outside diameter and a 10 feet long 29 AWG 4 conductor shielded Teflon cable. You will also find options for external matched output readily available.

The Miniature Load Button offers high accuracy and high stiffness. It has Nonlinearity of ±0.2% and Deflection of 0.002” nominal. The standard LLB300 Miniature Load Button can be modified or customized to meet your requirements and most capacities are in our inventory, making them available for 24 hour shipping.

Don’t get misled by the looks of the LLB300. It is not your usual load button, but a high performance cross beam sensor that delivers double the performance with half the footprint. Covering an impressive capacity range from 25 to 1000lb (11.34 to 453.6kg), this compact overachiever measures only 0.74in (18.8mm) in diameter and 0.25in (6.4mm) in height. As the solution of choice for many aerospace and military programs, LLB300 delivers outstanding performance in high temperature environments up to 250°F. It is also available in low outgassing, vacuum rated special order custom versions.

Thanks to FUTEK’s high fatigue optimized flexure design, the LLB300 has a rated non-linearity of only 0.2% which is less than half compared to other sensors that are available on the market. This market-leading performance is enabled by a special bridge configuration providing off axis cancellation with the cross beam structure. The precision-engineered liner crossbeam design gives the sensor a very high level of performance.

Wide range and flexibility

LLB300 series offers load buttons in six capacity options that measure compressive loads from 25 to 1000lb (11.34 to 453.6kg), a remarkable range for such a tiny package. Its highly flexible mounting options include securement from the outer lip, mounting using the threaded holes, retention with screws, or mounting inside a counterbore hold.

Robust construction

The stainless steel body provides outstanding strength and corrosion resistance and provides enhanced protection against physical damage in addition to withstanding other harsh environmental conditions. A special heat treatment process has been applied to the flexure to improve durability, extending the life-cycle of the sensor.

High natural frequency

The sensor delivers a remarkably high natural frequency (starting at 21.0kHz and going up to 58kHz) which provides a fast response time that benefits accuracy and cycle time reduction in dynamic applications. The precision of the sensor is also augmented by its high stiffness, which leads to a very low deflection with some capacities as low as 0.0003in (0.0076mm). In addition, special design and manufacturing touches further enhance the sensor’s performance, such as a highly customized strain element. Mechanical strain relief for the cable protects it from damage in dynamic environments.

Low power consumption

With a 700 Ohm bridge resistance, the LLB300 consumes around 50% less current than a traditional load button. This is especially valuable for any applications that are battery operated or are embedded in tight spaces where heat generation could become an issue.

Made to be accurate

The LLB300 has a rated non-linearity of only 0.2% and a deflection of 0.0007 to 0.001in nom. In addition, special design touches such as the unique cross-beam structure and a highly customized strain relief further enhance the sensor’s exceptional performance.

Designed for precision

The spherical radius of the load button has been designed to maintain the highest possible level of accuracy. By minimizing contact with the loading provisions, the button’s spherical shape transfers the load evenly over the sensing area, compensating for potential misalignments.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, low hysteresis and creep properties, and corrosion resistance over a wide temperature range.

Tough-as-nails cable

The sensor cable is a 29 AWG, 4-conductor, 10-foot (3m) long cable with spiral shielding and a Teflon outer jacket. It is a mechanically crimped cable with strain relief that enables a very high level of security for harsh environments.

Integrated temp compensation

The sensor is fully internally temperature compensated, and no external conditioning circuitry is required, which increases accuracy without increasing the cost. It also offers flexibility for cable routing and customization of the cable length.

Calibration included

The LLB300 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

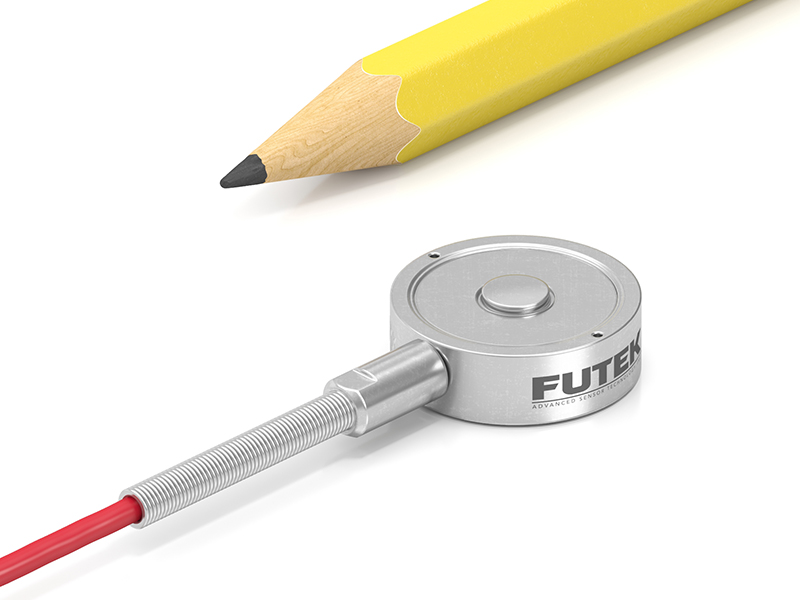

Compact overachiever for mission critical applications

Model LLB300 is a Miniature Load Button built for Press, or Inline compression applications. The standard LLB300 Miniature Load Button model has a very robust construction available in 17-4 Stainless Steel, with a 0.74” outside diameter and a 10 feet long 29 AWG 4 conductor shielded Teflon cable. You will also find options for external matched output readily available.

The Miniature Load Button offers high accuracy and high stiffness. It has Nonlinearity of ±0.2% and Deflection of 0.002” nominal. The standard LLB300 Miniature Load Button can be modified or customized to meet your requirements and most capacities are in our inventory, making them available for 24 hour shipping.

Don’t get misled by the looks of the LLB300. It is not your usual load button, but a high performance cross beam sensor that delivers double the performance with half the footprint. Covering an impressive capacity range from 25 to 1000lb (11.34 to 453.6kg), this compact overachiever measures only 0.74in (18.8mm) in diameter and 0.25in (6.4mm) in height. As the solution of choice for many aerospace and military programs, LLB300 delivers outstanding performance in high temperature environments up to 250°F. It is also available in low outgassing, vacuum rated special order custom versions.

Thanks to FUTEK’s high fatigue optimized flexure design, the LLB300 has a rated non-linearity of only 0.2% which is less than half compared to other sensors that are available on the market. This market-leading performance is enabled by a special bridge configuration providing off axis cancellation with the cross beam structure. The precision-engineered liner crossbeam design gives the sensor a very high level of performance.

Wide range and flexibility

LLB300 series offers load buttons in six capacity options that measure compressive loads from 25 to 1000lb (11.34 to 453.6kg), a remarkable range for such a tiny package. Its highly flexible mounting options include securement from the outer lip, mounting using the threaded holes, retention with screws, or mounting inside a counterbore hold.

Robust construction

The stainless steel body provides outstanding strength and corrosion resistance and provides enhanced protection against physical damage in addition to withstanding other harsh environmental conditions. A special heat treatment process has been applied to the flexure to improve durability, extending the life-cycle of the sensor.

High natural frequency

The sensor delivers a remarkably high natural frequency (starting at 21.0kHz and going up to 58kHz) which provides a fast response time that benefits accuracy and cycle time reduction in dynamic applications. The precision of the sensor is also augmented by its high stiffness, which leads to a very low deflection with some capacities as low as 0.0003in (0.0076mm). In addition, special design and manufacturing touches further enhance the sensor’s performance, such as a highly customized strain element. Mechanical strain relief for the cable protects it from damage in dynamic environments.

Low power consumption

With a 700 Ohm bridge resistance, the LLB300 consumes around 50% less current than a traditional load button. This is especially valuable for any applications that are battery operated or are embedded in tight spaces where heat generation could become an issue.

Made to be accurate

The LLB300 has a rated non-linearity of only 0.2% and a deflection of 0.0007 to 0.001in nom. In addition, special design touches such as the unique cross-beam structure and a highly customized strain relief further enhance the sensor’s exceptional performance.

Designed for precision

The spherical radius of the load button has been designed to maintain the highest possible level of accuracy. By minimizing contact with the loading provisions, the button’s spherical shape transfers the load evenly over the sensing area, compensating for potential misalignments.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, low hysteresis and creep properties, and corrosion resistance over a wide temperature range.

Tough-as-nails cable

The sensor cable is a 29 AWG, 4-conductor, 10-foot (3m) long cable with spiral shielding and a Teflon outer jacket. It is a mechanically crimped cable with strain relief that enables a very high level of security for harsh environments.

Integrated temp compensation

The sensor is fully internally temperature compensated, and no external conditioning circuitry is required, which increases accuracy without increasing the cost. It also offers flexibility for cable routing and customization of the cable length.

Calibration included

The LLB300 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.