Miniature Threaded Load Button

Compact, fast and accurate

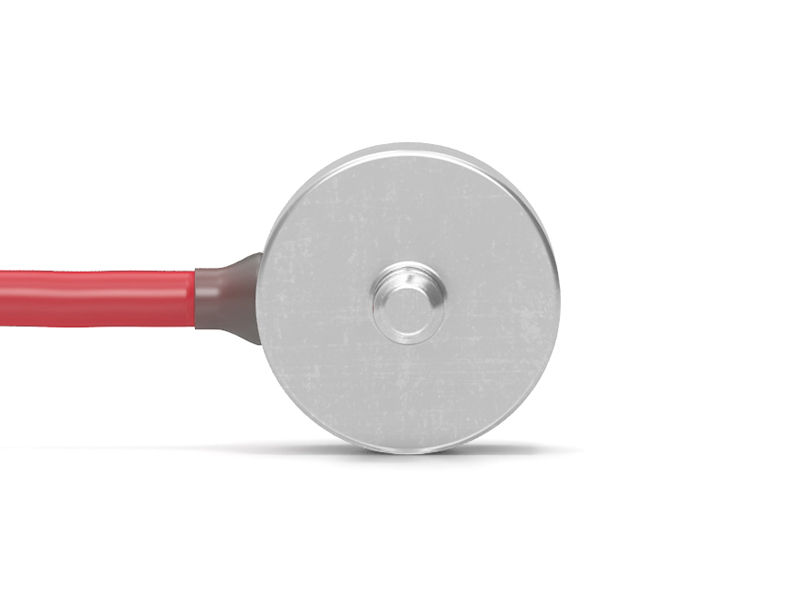

The diverse and durable LLB210 miniature threaded load button is an extraordinarily accurate miniature sensor. It features FUTEK’s custom single-piece integrated sensing element with internally embedded zero balance and thermal compensation, allowing for outstanding sensor reliability and performance.

The sensor is designed for press or inline compression applications, such as measuring loads on a turbine shaft or gauging forces on a CNC workpiece. Its design offers many possibilities for unique integration options with flexible mating accessories. The LLB210 is an optimal choice for critical compression applications that benefit from its miniature 0.38in (9.5mm) diameter and 0.32in (8.1mm) tall package, light 0.06lb (27.2g) weight, and impressive capacity range of 10 to 50lb (4.5kg to 22.6kg).

Flexible threaded mounting

The LLB210 is designed for applications requiring thread-mounted loading provisions where contact loading for a load button is not required. It is mounted using the threaded loading rod which is located on the top side of the sensor. The cable has a radial exit to the side which makes the sensor ideal for applications such as hydraulic presses that have vertical integration while requiring a side cable exit. The flexibility of this unique design also allows the user to create their own end effectors to achieve the optimal loading provision for their application.

Reducing error

A custom strain element design offers robust integration with the sensor case and very high accuracy and reliability. It completely eliminates inter-gauge wiring, leading to enhanced calibration performance. A customized strain element allows increased strain measurement around the active sensor element reducing reproducibility errors.

Made to be accurate

The LLB210 delivers a remarkably high natural frequency up to 31kHz which provides a fast response time that benefits accuracy and cycle time reduction. The precision of the sensor is also augmented by its high stiffness, which leads to deflection as low as 0.0007in (0.017mm).

Integrated temp compensation

The sensor is fully internally temperature compensated, and no external conditioning circuitry is required, which increases accuracy without increasing the cost. It also offers flexibility for cable routing and customization of the cable length.

Robust construction

The aerospace-grade stainless steel body provides outstanding strength and corrosion resistance and provides enhanced protection against physical damage in addition to withstanding other harsh environmental conditions. A special heat treatment process has been applied to the flexure to improve durability, extending the life-cycle of the sensor.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, and corrosion resistance over a wide temperature range.

Flexible cable

The LLB210 sensor is offered with a 29 AWG, 4-conductor cable with spiral shielding and a silicone outer jacket. The cable is highly flexible while still offering protection from outer interference.

Calibration included

The LLB210 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

Compact, fast and accurate

The diverse and durable LLB210 miniature threaded load button is an extraordinarily accurate miniature sensor. It features FUTEK’s custom single-piece integrated sensing element with internally embedded zero balance and thermal compensation, allowing for outstanding sensor reliability and performance.

The sensor is designed for press or inline compression applications, such as measuring loads on a turbine shaft or gauging forces on a CNC workpiece. Its design offers many possibilities for unique integration options with flexible mating accessories. The LLB210 is an optimal choice for critical compression applications that benefit from its miniature 0.38in (9.5mm) diameter and 0.32in (8.1mm) tall package, light 0.06lb (27.2g) weight, and impressive capacity range of 10 to 50lb (4.5kg to 22.6kg).

Flexible threaded mounting

The LLB210 is designed for applications requiring thread-mounted loading provisions where contact loading for a load button is not required. It is mounted using the threaded loading rod which is located on the top side of the sensor. The cable has a radial exit to the side which makes the sensor ideal for applications such as hydraulic presses that have vertical integration while requiring a side cable exit. The flexibility of this unique design also allows the user to create their own end effectors to achieve the optimal loading provision for their application.

Reducing error

A custom strain element design offers robust integration with the sensor case and very high accuracy and reliability. It completely eliminates inter-gauge wiring, leading to enhanced calibration performance. A customized strain element allows increased strain measurement around the active sensor element reducing reproducibility errors.

Made to be accurate

The LLB210 delivers a remarkably high natural frequency up to 31kHz which provides a fast response time that benefits accuracy and cycle time reduction. The precision of the sensor is also augmented by its high stiffness, which leads to deflection as low as 0.0007in (0.017mm).

Integrated temp compensation

The sensor is fully internally temperature compensated, and no external conditioning circuitry is required, which increases accuracy without increasing the cost. It also offers flexibility for cable routing and customization of the cable length.

Robust construction

The aerospace-grade stainless steel body provides outstanding strength and corrosion resistance and provides enhanced protection against physical damage in addition to withstanding other harsh environmental conditions. A special heat treatment process has been applied to the flexure to improve durability, extending the life-cycle of the sensor.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, and corrosion resistance over a wide temperature range.

Flexible cable

The LLB210 sensor is offered with a 29 AWG, 4-conductor cable with spiral shielding and a silicone outer jacket. The cable is highly flexible while still offering protection from outer interference.

Calibration included

The LLB210 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.