Miniature S-Beam Jr.® Load Cell

A powerful and durable miniature load cell

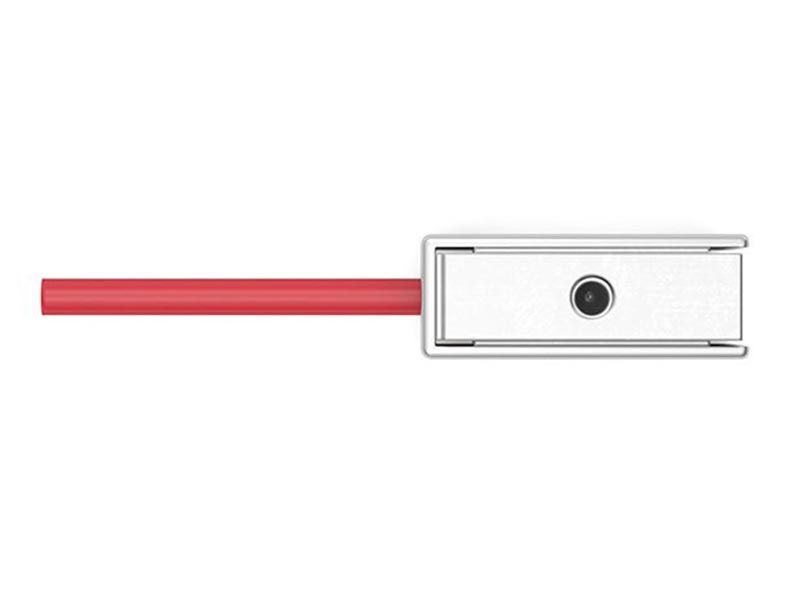

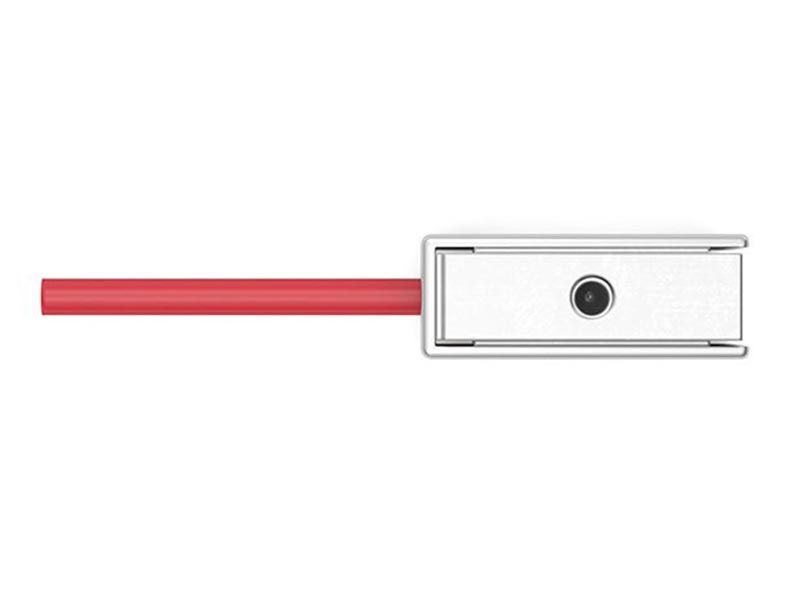

LSB200 is a miniature high-performance S Beam Jr.® load cell suitable for a wide range of applications. The highly accurate load cell has a height of only 0.75in, which makes it suitable for tight environments and applications with limited space.

Featuring integrated overload protection and available in a wide range of capacities from 10g to 250g, this ultralight load cell is one of FUTEK’s most popular sensors for applications that require high durability and accuracy in a small footprint.

LSB200 is also available in versions that are non-magnetic, have vacuum compatibility, higher IP rating, and high temperature compensation. It can also be modified to suit OEM applications. FUTEK offers application and engineering resources during DFM/DFX stage upon request.

Compact package

With dimensions of only 0.75in (H) × 0.26in (W) × 0.69in (L) (19.1mm × 6.7mm × 17.5mm) and a weight of only 0.3oz (9g), the highly compact LSB200 sensor can be used in applications where other sensors of similar capacity just won’t fit because of size constraints.

Overload protection

FUTEK’s LSB200 has 1000% overload stop capability for tension and compression. The unique overload stop design protects the sensor from damage during accidental overload. It also decreases the risk of mechanical breakage and yield as the overload stop helps to stop the part from deflecting, which prevents the metal from going into its yield state.

Highly accurate

The LSB200 delivers a highly accurate performance with a deflection of >0.01in nominal and nonlinearity starting at ±0.1%.

Excellent thermal performance

LSB200 provides reliable performance over a wide temperature range: –60 to 200°F (–50 to 93°C). The excellent thermal performance allows you to use the sensor in various applications and environments.

Best-in-class material

LSB200 is available in aerospace-grade aluminum. The aluminum construction for the 10 to 250g capacities provides superior performance, resistance to a wide range of harsh environmental conditions, and an extremely long life span.

Calibration included

The LSB200 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

A powerful and durable miniature load cell

LSB200 is a miniature high-performance S Beam Jr.® load cell suitable for a wide range of applications. The highly accurate load cell has a height of only 0.75in, which makes it suitable for tight environments and applications with limited space.

Featuring integrated overload protection and available in a wide range of capacities from 10g to 250g, this ultralight load cell is one of FUTEK’s most popular sensors for applications that require high durability and accuracy in a small footprint.

LSB200 is also available in versions that are non-magnetic, have vacuum compatibility, higher IP rating, and high temperature compensation. It can also be modified to suit OEM applications. FUTEK offers application and engineering resources during DFM/DFX stage upon request.

Compact package

With dimensions of only 0.75in (H) × 0.26in (W) × 0.69in (L) (19.1mm × 6.7mm × 17.5mm) and a weight of only 0.3oz (9g), the highly compact LSB200 sensor can be used in applications where other sensors of similar capacity just won’t fit because of size constraints.

Overload protection

FUTEK’s LSB200 has 1000% overload stop capability for tension and compression. The unique overload stop design protects the sensor from damage during accidental overload. It also decreases the risk of mechanical breakage and yield as the overload stop helps to stop the part from deflecting, which prevents the metal from going into its yield state.

Highly accurate

The LSB200 delivers a highly accurate performance with a deflection of >0.01in nominal and nonlinearity starting at ±0.1%.

Excellent thermal performance

LSB200 provides reliable performance over a wide temperature range: –60 to 200°F (–50 to 93°C). The excellent thermal performance allows you to use the sensor in various applications and environments.

Best-in-class material

LSB200 is available in aerospace-grade aluminum. The aluminum construction for the 10 to 250g capacities provides superior performance, resistance to a wide range of harsh environmental conditions, and an extremely long life span.

Calibration included

The LSB200 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.