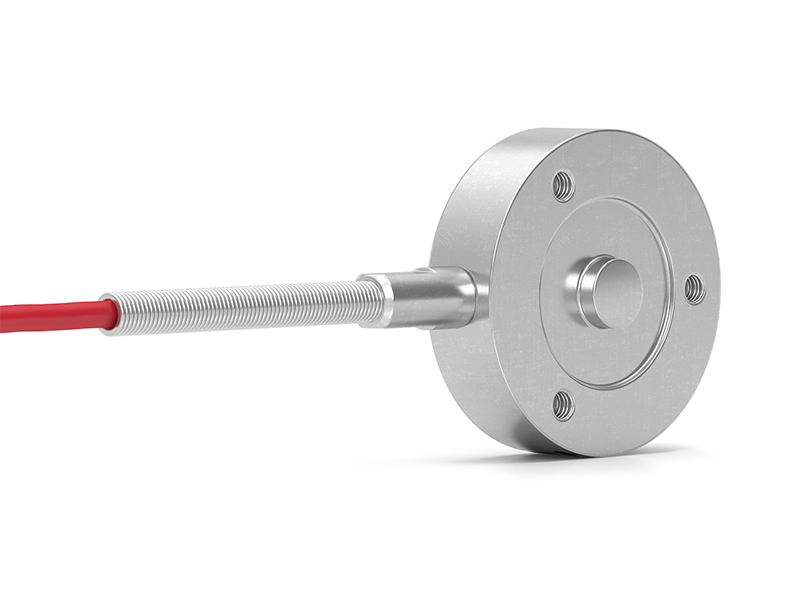

Miniature Load Button with Threaded/Tapped Holes

Compact and durable load button for press compression applications

The unrivaled durability and accuracy of the miniature load button LLB350 has made it a very popular choice for press compression applications. The sensor has a compact form factor with a diameter of only 0.98in (24.9mm) and a height of only 0.32in (8.1mm), a capacity 25 to 50lb (11.34 to 22.6kg), and screw down mounting provisions for ease of fixturing and integration. LLB350 fuses an internally balanced and thermally compensated bridge with mechanical cable strain relief, creating the ultimate combination of performance and reliability. This model can also be modified to suit OEM applications. FUTEK offers application and engineering resources during DFM/DFX stage upon request.

Range and mounting

The LLB350 series offers load buttons in two capacity options that measure compressive loads from 25 to 50lb (11.34 to 22.6kg). Three threaded holes allows the part to be securely mounted from the bottom.

Robust construction

The sensor’s aerospace alloy stainless steel body provides not only outstanding creep and fatigue performance, but also corrosion resistance and enhanced protection against harsh environments. A special heat treatment process has been applied to the flexure to improve durability, extending the life-cycle of the sensor.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, and corrosion resistance over a wide temperature range.

Made to be accurate

The LLB350 has a rated non-linearity and hysteresis of ±0.5% with 0.1% non-repeatability. Its precision is also augmented by its high stiffness, which leads to a very low deflection with some capacities as low as 0.0005in (0.0127mm).

Designed for precision

The spherical radius of the load button has been designed to maintain the highest possible level of accuracy. By minimizing contact with the loading provisions, the button’s spherical shape transfers the load evenly over the sensing area, compensating for potential misalignments.

Tough-as-nails cable

The sensor cable is a 29 AWG, 4-conductor, 10-foot (3m) long cable with spiral shielding and a Teflon outer jacket. It is a mechanically crimped cable with strain relief that enables a very high level of security for harsh environments where the cable undergoes thousands and thousands of bend-unbend cycles.

Calibration included

The LLB350 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

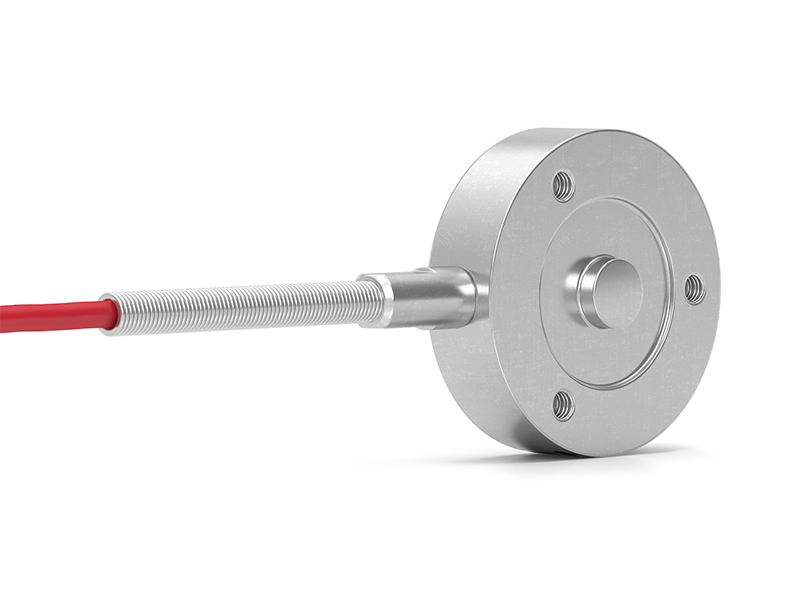

Compact and durable load button for press compression applications

The unrivaled durability and accuracy of the miniature load button LLB350 has made it a very popular choice for press compression applications. The sensor has a compact form factor with a diameter of only 0.98in (24.9mm) and a height of only 0.32in (8.1mm), a capacity 25 to 50lb (11.34 to 22.6kg), and screw down mounting provisions for ease of fixturing and integration. LLB350 fuses an internally balanced and thermally compensated bridge with mechanical cable strain relief, creating the ultimate combination of performance and reliability. This model can also be modified to suit OEM applications. FUTEK offers application and engineering resources during DFM/DFX stage upon request.

Range and mounting

The LLB350 series offers load buttons in two capacity options that measure compressive loads from 25 to 50lb (11.34 to 22.6kg). Three threaded holes allows the part to be securely mounted from the bottom.

Robust construction

The sensor’s aerospace alloy stainless steel body provides not only outstanding creep and fatigue performance, but also corrosion resistance and enhanced protection against harsh environments. A special heat treatment process has been applied to the flexure to improve durability, extending the life-cycle of the sensor.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, and corrosion resistance over a wide temperature range.

Made to be accurate

The LLB350 has a rated non-linearity and hysteresis of ±0.5% with 0.1% non-repeatability. Its precision is also augmented by its high stiffness, which leads to a very low deflection with some capacities as low as 0.0005in (0.0127mm).

Designed for precision

The spherical radius of the load button has been designed to maintain the highest possible level of accuracy. By minimizing contact with the loading provisions, the button’s spherical shape transfers the load evenly over the sensing area, compensating for potential misalignments.

Tough-as-nails cable

The sensor cable is a 29 AWG, 4-conductor, 10-foot (3m) long cable with spiral shielding and a Teflon outer jacket. It is a mechanically crimped cable with strain relief that enables a very high level of security for harsh environments where the cable undergoes thousands and thousands of bend-unbend cycles.

Calibration included

The LLB350 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.