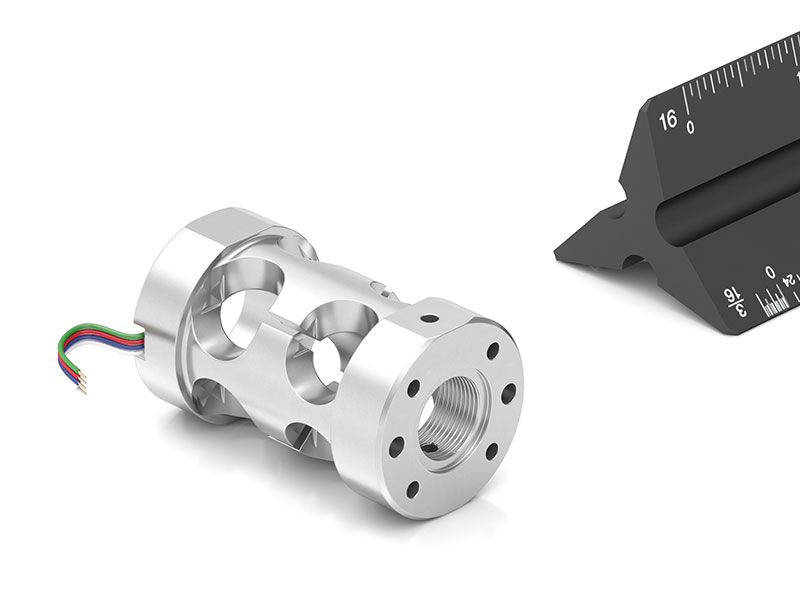

OEM Flange-to-Flange Reaction Torque Sensor

Compact design for easy OEM integration

The TFF325 is a compact and lightweight reaction torque sensor designed for torque auditing, specifically for high-volume OEM applications.

The flange-to-flange sensor is a highly sensitive and reliable solution that uses advanced metal foil strain gauge technology. It’s available in capacities ranging from 20in-oz to 100in-lb and frequencies between 263 and 4159Hz. The TFF325 can be also customized to suit your unique requirements.

Easy integration into OEM applications

The unit’s unique through-hole design allows users to easily integrate the sensor into a wide range of OEM applications. With an 0.446in (11.3mm) internal diameter and 1.2in (30.5mm) outer diameter, the unit offers a small footprint when space is at a premium. Six inches of lead wires allow the user to customize the cable according to their requirements.

Aluminum construction

The sensor body is constructed with high-quality Aluminum 2024-T4 that is a light and high strength material that offers good machinability and high fatigue resistance.

Calibration included

The TFF325 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

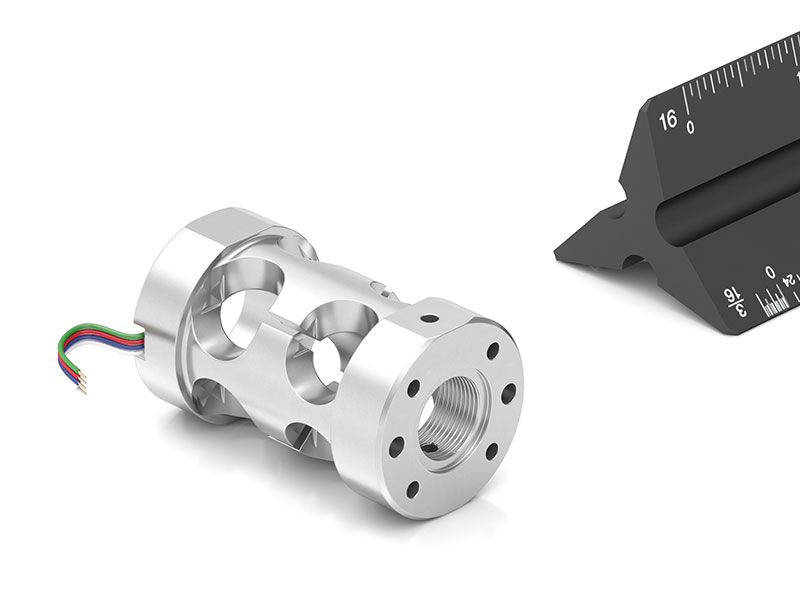

Compact design for easy OEM integration

The TFF325 is a compact and lightweight reaction torque sensor designed for torque auditing, specifically for high-volume OEM applications.

The flange-to-flange sensor is a highly sensitive and reliable solution that uses advanced metal foil strain gauge technology. It’s available in capacities ranging from 20in-oz to 100in-lb and frequencies between 263 and 4159Hz. The TFF325 can be also customized to suit your unique requirements.

Easy integration into OEM applications

The unit’s unique through-hole design allows users to easily integrate the sensor into a wide range of OEM applications. With an 0.446in (11.3mm) internal diameter and 1.2in (30.5mm) outer diameter, the unit offers a small footprint when space is at a premium. Six inches of lead wires allow the user to customize the cable according to their requirements.

Aluminum construction

The sensor body is constructed with high-quality Aluminum 2024-T4 that is a light and high strength material that offers good machinability and high fatigue resistance.

Calibration included

The TFF325 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.