Micro Slip-Ring Shaft-to-Shaft Rotary Torque Sensor

Transformative miniature that pushes boundaries

The TRS150 Rotary Torque Sensor is a state-of-the-art, miniature sensor designed for applications where traditional torque measurements have been challenging. With its compact dimensions—0.7 inches by 0.7 inches (17mm x 17mm) cross-section and a length of 2.01 inches (53mm)—the TRS150 is the smallest rotary torque sensor in FUTEK's catalog, offering exceptional performance in space-constrained environments. It features a 5mm male shaft-to-shaft with flats, capable of accurately measuring torque up to 2 Nm in rotational systems operating at speeds up to 150 RPM.

Engineered for precision, the TRS150 boasts impressive performance specifications, including a nonlinearity of ± 0.1% of rated output, hysteresis of ± 0.2% of rated output, and nonrepeatability of ± 0.05% of rated output. These specifications ensure highly reliable and accurate torque measurements, even in demanding applications. The sensor also includes a custom-built slip ring that facilitates precise signal transfer from the rotating shaft to the stationary stator, supported by high-precision machining.

With its robust construction—featuring a 17-4PH stainless steel shaft with flats and aluminum housing, and compliance with RoHS standards—the TRS150 is an indispensable solution for engineers seeking precise and reliable torque measurements in compact, space-limited environments.

The TRS150 rotary torque sensor is a state-of-the-art miniature sensor that pushes technical boundaries in applications where torque measurements have previously not been possible.

With a 0.7in × 0.7in (17mm × 17mm) cross section and 2.01in (53mm) length, the TRS150 is the smallest rotary torque sensor on the market*. It has two available shaft diameters: 0.19 inches (5mm) for 0.5 N·m and 1 N·m capacities, and 0.23 inches (6mm) for 2 N·m capacities, capable of measuring torque up to 300 rpm.

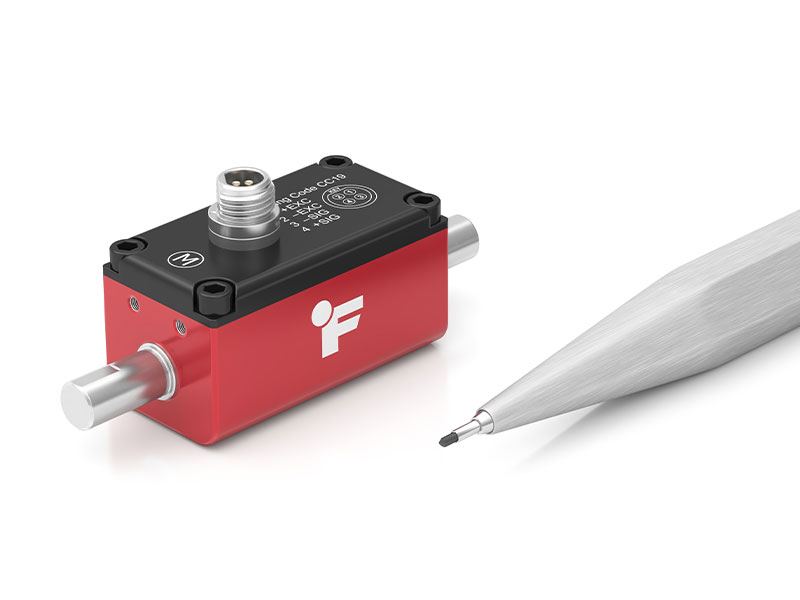

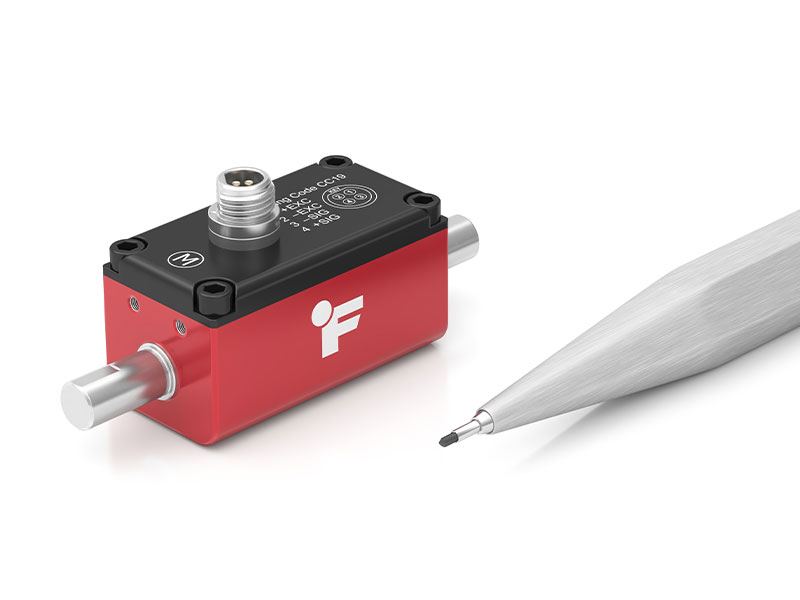

Industry’s Smallest Rotary Torque Sensor

The TRS150 is the smallest rotary torque sensor on the market*, roughly the size of a finger — yet it delivers uncompromised performance. Its ultra-compact form factor and lightweight 1 oz (28 g) design enable seamless integration into tight assemblies where space and mass are at a premium.

* According to our research

Static & Dynamic Measurement

The TRS150 features an integrated slip ring that enables torque signal transmission from the rotating shaft to the stator, allowing continuous measurement from stall to full rotation. Its precision-machined components ensure consistent, high-accuracy torque readings. This sensor offers nonlinearity of ±0.1% of RO, hysteresis of ±0.2% of RO, and non repeatability of ±0.05% of RO. The TRS150 supports a safe overload capacity of up to 150%.

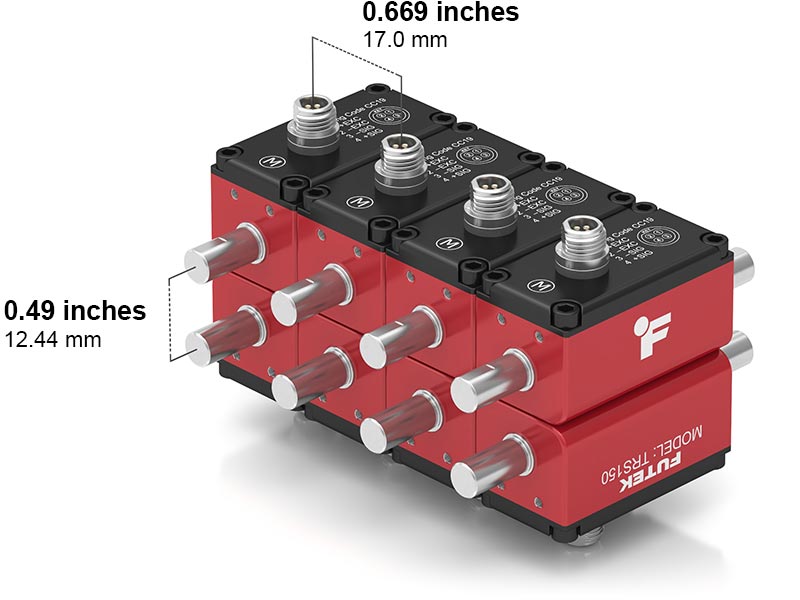

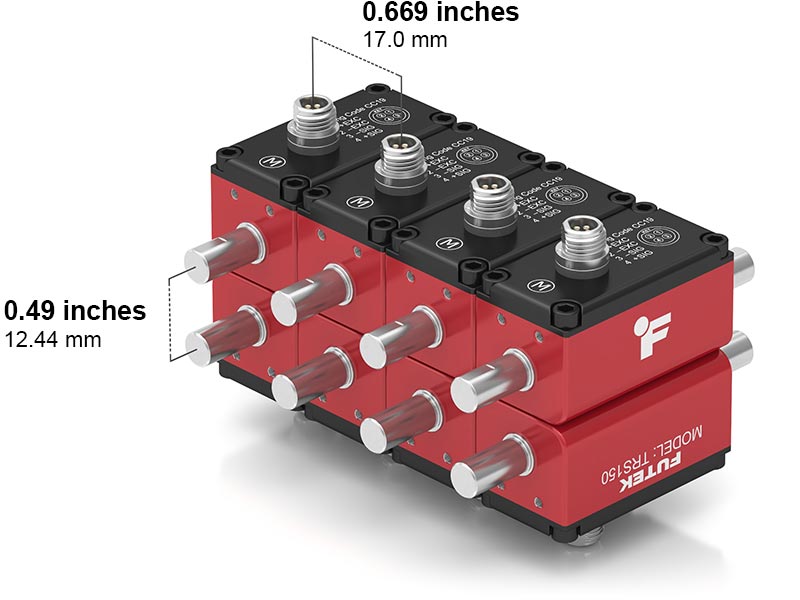

Designed for Tight-Space Assemblies

The TRS150’s miniature envelope (0.67" [17 mm] width) enables seamless integration in tight assemblies. Its compact design allows side-by-side sensor placement with a minimal shaft-to-shaft distance (0.49" [12.44 mm] or 0.67" [17 mm], depending on orientation). Operating on low power with a maximum of 10 VDC excitation, the sensor is ideal for integration into portable or battery-operated systems where minimal heat generation and power consumption are critical. Ideal for precision applications like high-density robotics and specialized manufacturing, the TRS150 maximizes functionality while minimizing footprint — making every millimeter count.

Easy Installation and Flexible Connectivity

The 4-position micro receptacle on this unit simplifies installation by allowing quick and secure cable connections. Its design enables easy cable replacement, providing flexibility in cable length to suit different application needs. Using a detachable mating cable also reduces maintenance costs, as damaged or worn cables can be replaced without replacing the entire unit. This enhances adaptability while ensuring a reliable and cost-effective connectivity solution. The TRS150 is compatible with FUTEK’s IHH500, USB520, IPM650, and other industry-standard signal conditioners.

Wide range of applications

This miniature torque sensor supports both static and dynamic measurements, making it ideal for portable and power-sensitive systems. Its compact size and high sensitivity are optimized for integration into dense assemblies such as high-density surgical robotics tooling.

Best-in-class material

The TRS150 is built for durability and long-term reliability. Its main body is constructed from aerospace-grade 17-4PH stainless steel, offering high strength, hardness, and corrosion resistance across a broad temperature range. The red housing is anodized aluminum making it more resistant to wear and corrosion.

Calibration available

A certificate of conformance can be ordered on request. The sensor will be rigorously tested by FUTEK’s world class calibration department whose proprietary and innovative processes exceed the stringent ANSI Z540-1 and ISO 17025 standards. We can also reduce your setup time by calibrating your sensor of choice with an amplifier.

Transformative miniature that pushes boundaries

The TRS150 Rotary Torque Sensor is a state-of-the-art, miniature sensor designed for applications where traditional torque measurements have been challenging. With its compact dimensions—0.7 inches by 0.7 inches (17mm x 17mm) cross-section and a length of 2.01 inches (53mm)—the TRS150 is the smallest rotary torque sensor in FUTEK's catalog, offering exceptional performance in space-constrained environments. It features a 5mm male shaft-to-shaft with flats, capable of accurately measuring torque up to 2 Nm in rotational systems operating at speeds up to 150 RPM.

Engineered for precision, the TRS150 boasts impressive performance specifications, including a nonlinearity of ± 0.1% of rated output, hysteresis of ± 0.2% of rated output, and nonrepeatability of ± 0.05% of rated output. These specifications ensure highly reliable and accurate torque measurements, even in demanding applications. The sensor also includes a custom-built slip ring that facilitates precise signal transfer from the rotating shaft to the stationary stator, supported by high-precision machining.

With its robust construction—featuring a 17-4PH stainless steel shaft with flats and aluminum housing, and compliance with RoHS standards—the TRS150 is an indispensable solution for engineers seeking precise and reliable torque measurements in compact, space-limited environments.

The TRS150 rotary torque sensor is a state-of-the-art miniature sensor that pushes technical boundaries in applications where torque measurements have previously not been possible.

With a 0.7in × 0.7in (17mm × 17mm) cross section and 2.01in (53mm) length, the TRS150 is the smallest rotary torque sensor on the market*. It has two available shaft diameters: 0.19 inches (5mm) for 0.5 N·m and 1 N·m capacities, and 0.23 inches (6mm) for 2 N·m capacities, capable of measuring torque up to 300 rpm.

Industry’s Smallest Rotary Torque Sensor

The TRS150 is the smallest rotary torque sensor on the market*, roughly the size of a finger — yet it delivers uncompromised performance. Its ultra-compact form factor and lightweight 1 oz (28 g) design enable seamless integration into tight assemblies where space and mass are at a premium.

* According to our research

Static & Dynamic Measurement

The TRS150 features an integrated slip ring that enables torque signal transmission from the rotating shaft to the stator, allowing continuous measurement from stall to full rotation. Its precision-machined components ensure consistent, high-accuracy torque readings. This sensor offers nonlinearity of ±0.1% of RO, hysteresis of ±0.2% of RO, and non repeatability of ±0.05% of RO. The TRS150 supports a safe overload capacity of up to 150%.

Designed for Tight-Space Assemblies

The TRS150’s miniature envelope (0.67" [17 mm] width) enables seamless integration in tight assemblies. Its compact design allows side-by-side sensor placement with a minimal shaft-to-shaft distance (0.49" [12.44 mm] or 0.67" [17 mm], depending on orientation). Operating on low power with a maximum of 10 VDC excitation, the sensor is ideal for integration into portable or battery-operated systems where minimal heat generation and power consumption are critical. Ideal for precision applications like high-density robotics and specialized manufacturing, the TRS150 maximizes functionality while minimizing footprint — making every millimeter count.

Easy Installation and Flexible Connectivity

The 4-position micro receptacle on this unit simplifies installation by allowing quick and secure cable connections. Its design enables easy cable replacement, providing flexibility in cable length to suit different application needs. Using a detachable mating cable also reduces maintenance costs, as damaged or worn cables can be replaced without replacing the entire unit. This enhances adaptability while ensuring a reliable and cost-effective connectivity solution. The TRS150 is compatible with FUTEK’s IHH500, USB520, IPM650, and other industry-standard signal conditioners.

Wide range of applications

This miniature torque sensor supports both static and dynamic measurements, making it ideal for portable and power-sensitive systems. Its compact size and high sensitivity are optimized for integration into dense assemblies such as high-density surgical robotics tooling.

Best-in-class material

The TRS150 is built for durability and long-term reliability. Its main body is constructed from aerospace-grade 17-4PH stainless steel, offering high strength, hardness, and corrosion resistance across a broad temperature range. The red housing is anodized aluminum making it more resistant to wear and corrosion.

Calibration available

A certificate of conformance can be ordered on request. The sensor will be rigorously tested by FUTEK’s world class calibration department whose proprietary and innovative processes exceed the stringent ANSI Z540-1 and ISO 17025 standards. We can also reduce your setup time by calibrating your sensor of choice with an amplifier.