6 reasons why you should upgrade to FUTEK’s USB

FUTEK has just released USB225 Pro, the latest and greatest in our USB series of digital strain gauge signal conditioners. These groundbreaking products have changed the game for measurement electronics. But are they right for your needs? Brandon King, who leads FUTEK’s software development, breaks down why a switch to the USB series will benefit your application.

Tell me why I should use the USB series?

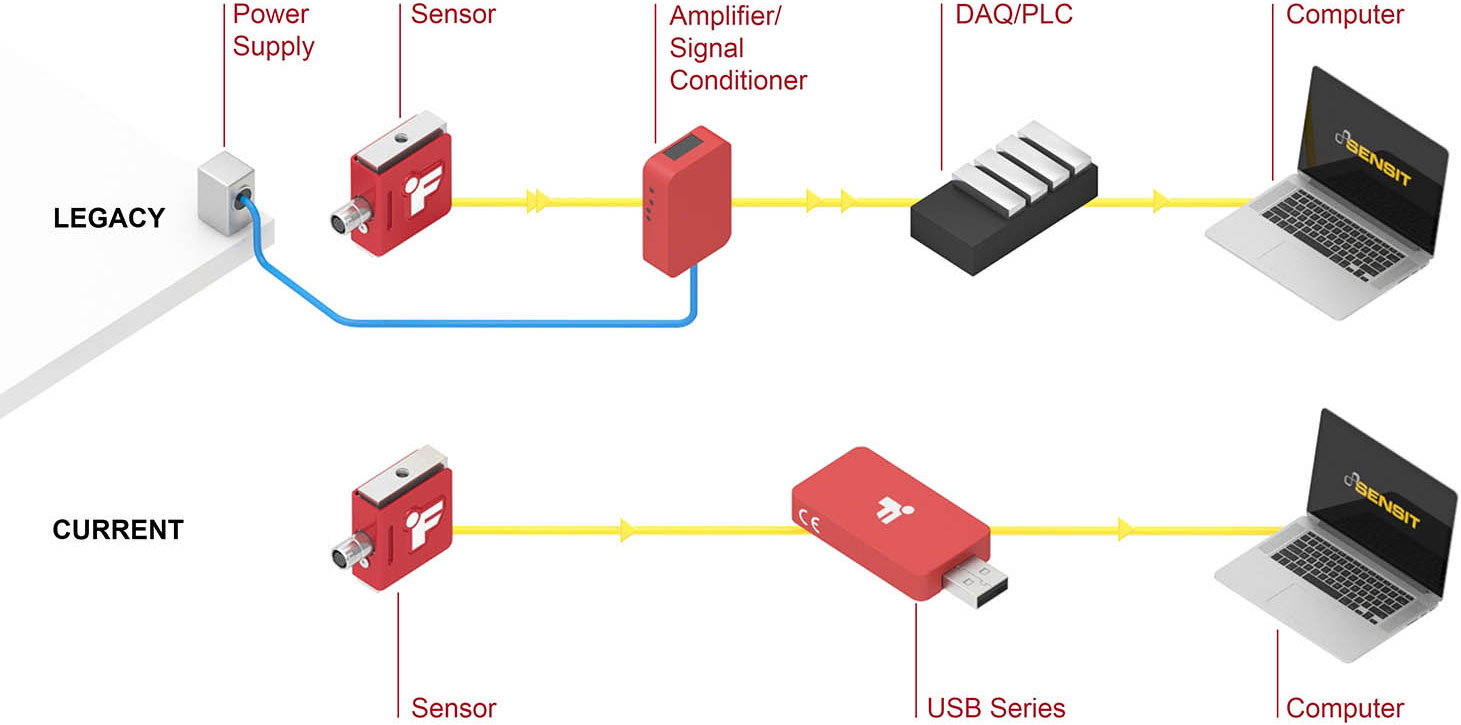

One good reason is for ease of use, what we call “plug and play”. So, for example, a traditional setup might include a sensor, an amplifier, and an instrument that can read the voltage coming out of the amplifier, whether that's a data acquisition system or a digital multimeter or something like that. The USB replaces those components so you can just have a sensor and the little USB module that you just connect directly to your computer.

Why is that useful?

Because it can replace a traditional amplifier or data acquisition system, which makes your system very streamlined and portable. The USB has all of that functionality in one small package. This is especially beneficial for one-off type applications, like when you’re working with simple test and measurement applications in a laboratory-type environment, because it gives you a quick and easy way to get started taking measurements.

That sounds good, but I’m still not convinced. What other advantages are there?

The main benefits are size, performance, and quality. These units are a half or a third of the size of comparable devices on the market. They also have a lot of powerful capabilities, such as built-in fault detection, enhanced accuracy performance and stability with a non-linearity of less than 0.002%. And because we are the manufacturer, we are in complete control of the production process. It’s our team that designs the USBs and develops them, tests them, and calibrates them. We don’t outsource any of that, like many manufacturers do. To make the spec variations between the models clearer, we have included this handy chart that maps out the different features and capabilities between the USB models.

| Key Features | USB220 (previous version) | USB225 Pro (newest version) |

|---|---|---|

| Fault Detection | yes | |

| On-Board Temperature Measurement | yes | |

| Shunt (kΩ) | 60.4 | 43/60.4/150 |

| Min Sampling Rate (SPS) | 5 | 2.5 |

| Max Sampling Rate (SPS) | 4,800 | 4,800 |

| Max Noise Free Resolution (Bits) | 17.8 at 3.4mV/V | 20 at 5mV/V |

| Input Range at Maximum Gain (mV/V) | ±3.4 | ±16 |

| Non-linearity (% of FSR) | ± 0.005% | ± 0.002% |

| Temperature Stability/Drift (ppm/°C) | 10 | 5 |

Can I use USB for other applications than testing measurements?

Yes. You can use our USBs in applications that are in larger systems, for example those that design automation or use some type of feedback and control. But in those cases you may not be able to use our SENSIT software (please note that you need to use SENSIT 2.7, the latest version, for USB225 Pro). You will probably need to develop some type of custom software to communicate with our devices. For that we have software libraries that you can utilize to communicate with the USBs.

Do I have to use FUTEK sensors to use the USB series in my system?

No. The USBs will take any millivolt per volt (mV/V) input, it doesn’t matter who the manufacturer is.

How easy is it to switch over from my existing system to this one? Is it really just “plug and play”?

Yes, it’s actually really simple. Your sensor connects directly to the USB module, so you can just connect whatever type of sensor that you have to the USB, plug it into the computer, and the computer should automatically recognize the USB device. Our newest model, USB225 Pro, comes with a mating connector that you can use to integrate into your sensor. It’s small and compact and even easier to work with than the USB220 connector. For those who prefer it, we can also offer the service to do the integration. We also provide services like system calibrations for more accurate measurements.