High Resolution & Sampling USB Data Acquisition

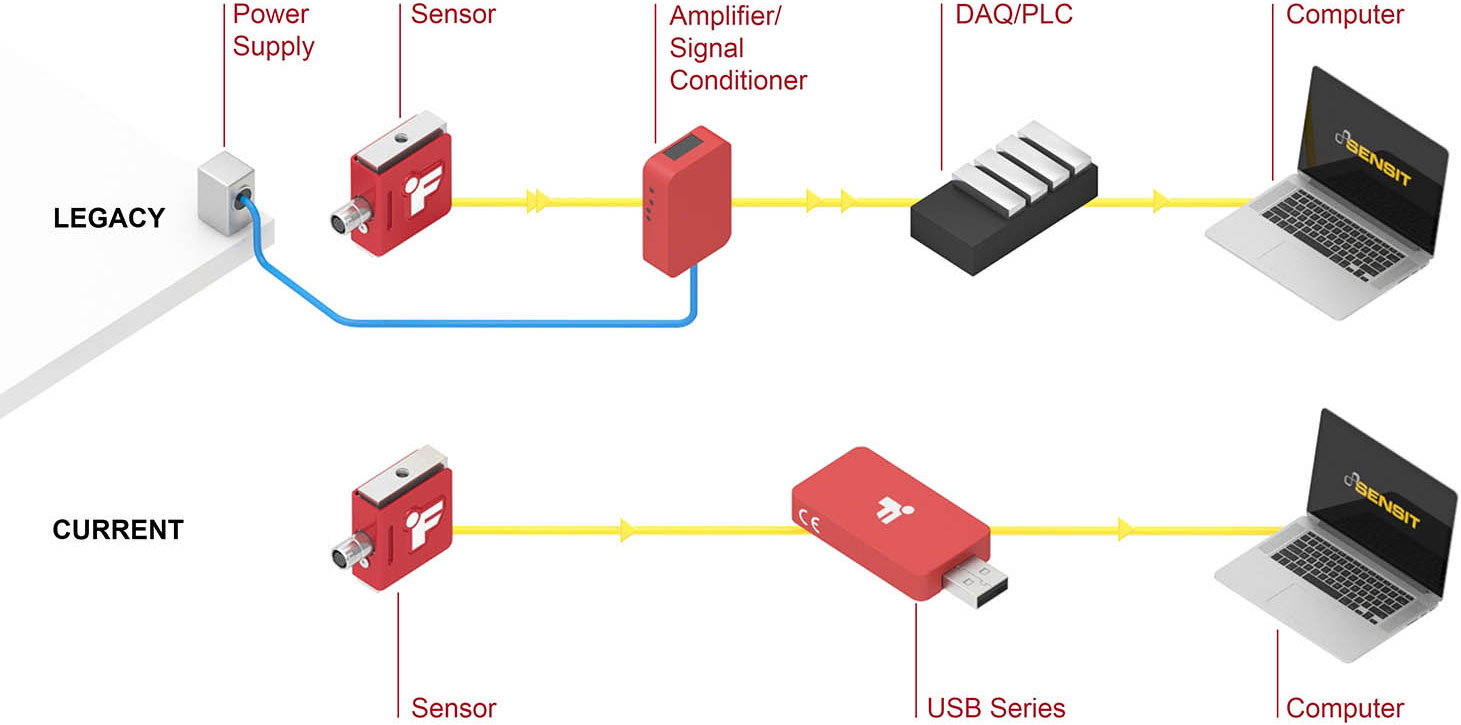

The assembly and setup of a sensor platform have vastly improved with the introduction of USB. The traditional assembly of a sensor platform involved a sensor, an amplifier, a power supply, a strain gauge data acquisition system (i.e. strain gauge DAQ), and software, on occasion a filter, and then a PC to capture and store the data. Though traditional platforms are suitable for most test-measurement applications, they carry a laundry list of “side effects” with them. Cost, space, noise, accuracy, convenience, and temperature co-efficiency all become variables within that traditional setup. What the industry needed was a fast data exchange solution that wouldn’t be phased by such “side effects.” And there lay the answer, a single-unit solution – the USB module.

FUTEK’s line of USB force sensor amplifiers is a modern, single-unit solution that eliminates the need for external amplifiers (or force sensor signal conditioners), filters, ADC modules, and power supply. The USB digital load cell amplifier is powered by the PC USB bus, which provides excitation voltage for the force sensor. The USB Family handles sensors with amplified voltage output (± VDC), amplified current ( ± mA), low-voltage mV/V output as well as Encoder TTL signals encountered in rotary torque sensors.

The sampling rate can be configured up to 38,400 Samples per Second (SPS), which is suitable for high-frequency applications where the quantification of forces and moments requires high sampling rates. All USB signal conditioners start at an internal resolution of 24 bits, and up to 21 Bits of noise-free resolution (NFR).

The easy plug-and-play setup is quick and the total measurement system cost is lower when compared to a traditional sensor system.

With the introduction of our USB Technology, FUTEK designed the SENSIT software to capture all of your test and measurement data. SENSIT Test and Measurement Software is a strain gauge data logger that displays the Peak/Valley, Tare/Gross and allows full data logging and live graphing capabilities.