What are the Types of Load Cells? | Load Cell Types | FUTEK

Load Cell Types: What are the types of Load Cells?

Although there several technologies to measuring force, we will focus on the most common type of load cell: metal foil strain gauge. Within the load cell types, there are a variety of body shapes and geometries, each one catering to distinct applications. Get to know the most noteworthy load cell types and geometries:

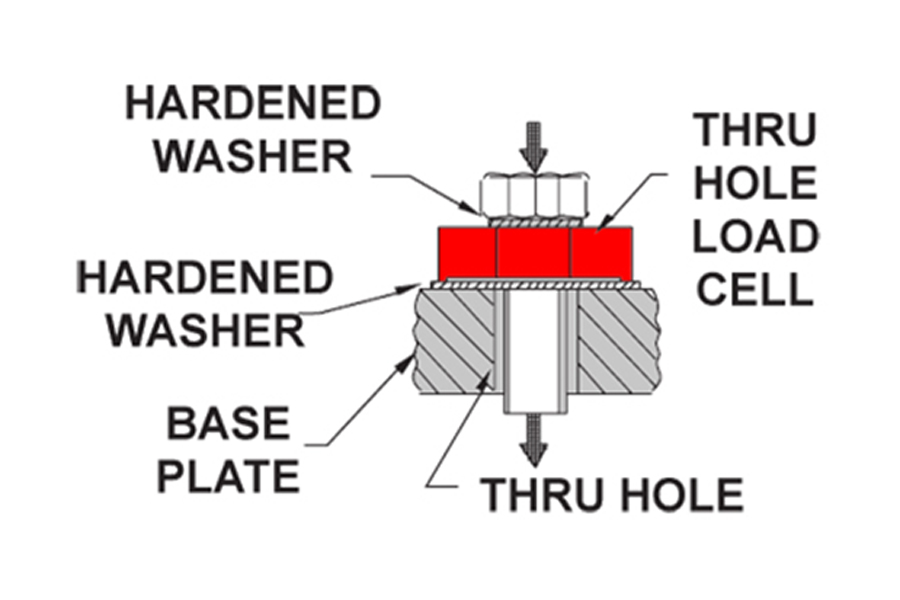

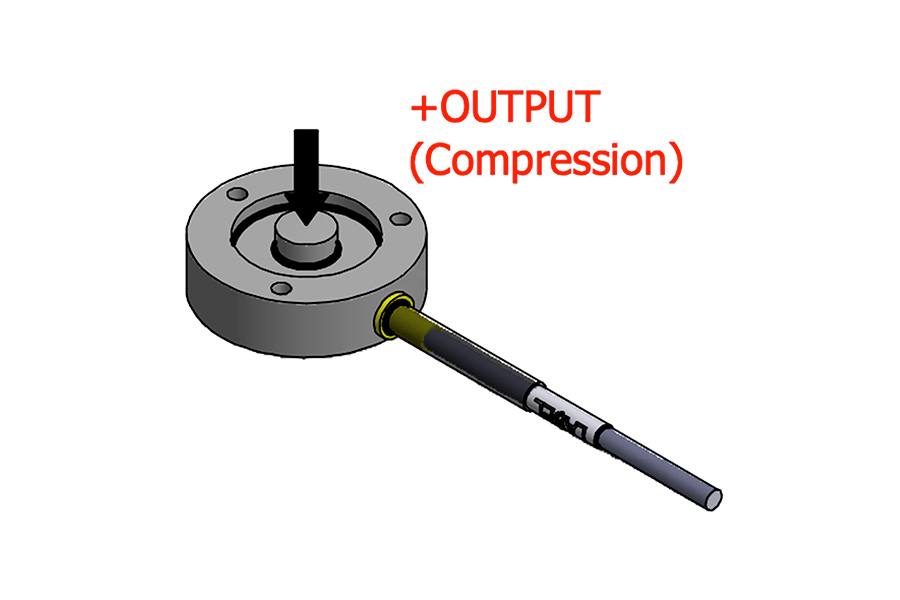

Thru Hole Load Cell

Donut Load Cell (aka Thru Hole load Cell) is a variation of a low profile compression load cell and features a compact, smooth thru-hole inner diameter design for use in applications to measure compressive loads which require a rod to pass thru the sensor center. One of the primary uses of this sensor type is to measure bolt loading.

Typical applications include press, Inline compression applications, bolt force measurements (bolt loading), clamping forces, overload monitoring post or leg mount, anchor load cell, and rolling mill systems

LTH350 Donut/Through Hole Load Cell

LTH350 Donut/Through Hole Load Cell LTH Series - Donut Thru Hole Load Cell

LTH Series - Donut Thru Hole Load Cell Donut Load Cell - Force Washer Load Cell / Bolt Fastening Application / Clamping Force.

Donut Load Cell - Force Washer Load Cell / Bolt Fastening Application / Clamping Force. QLA238 Custom Thru Hole Donut Load Cell

QLA238 Custom Thru Hole Donut Load CellVisit our Donut Thru Hole page to learn more!

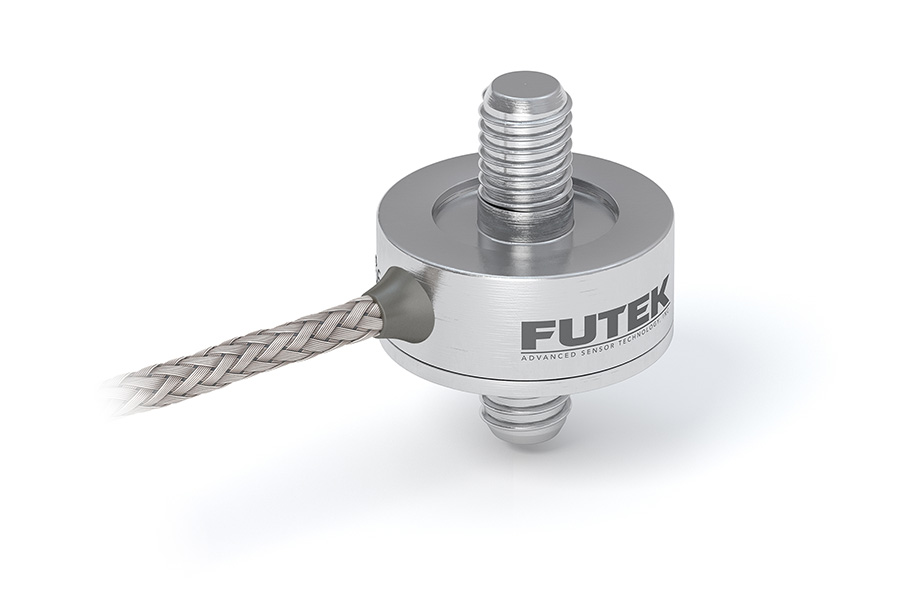

In Line Load Cell

Most commonly referred to as in line force transducers force sensor with male threads. This style of load force transducer can be used in both tension and compression loading applications. In line load cell sensors offer robust construction, high accuracy, high stiffness, and broad capacity range with minimal mounting clearance needed. They are great for endurance and press applications. FUTEK has also developed a miniature Inline Load Cell for applications where size and tight environments are critical.

LCM100 Miniature In Line Threaded Load Cell

LCM100 Miniature In Line Threaded Load Cell LCM325 Threaded In Line Load Cell

LCM325 Threaded In Line Load Cell LCM In Line Load Cell Series

LCM In Line Load Cell Series LCM550 High Capacity In Line Load Cell

LCM550 High Capacity In Line Load CellVisit our In Line Load Cell page to learn more!

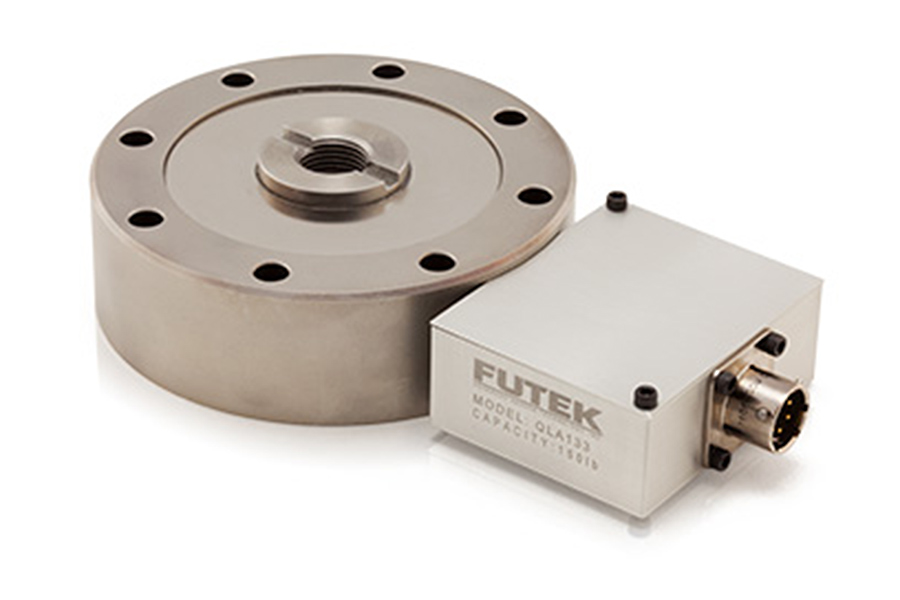

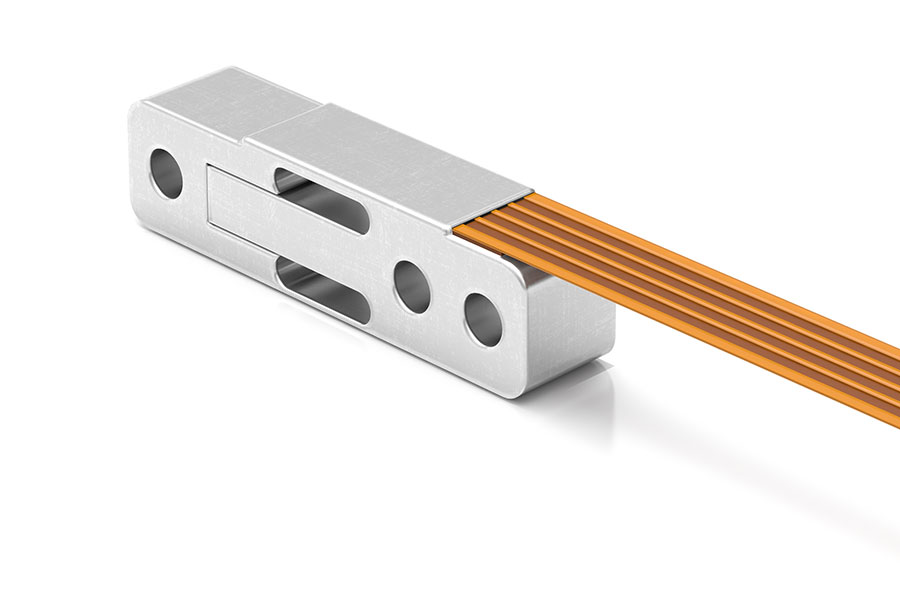

Pancake Load Cell

Pancake Load Cells, also known as low profile, universal Load Cells or shear web load cells, are commonly used in applications that require high precision, and less sensitive to load condition. For most capacities the Univeral Pancake Load Cell is normally designed with multiple shear struts. For lower capacities it's designed with bending beams. If properly designed and manufactured, the nature of its structure is less sensitive to extraneous load and moments (especially Torque) compared to other inline sensors such as the S Beam Load Cell, diaphragm or column type. This type of Load Cell is normally used in press in compression for controlling the applied load or pressure during the test or production, such as press-fit force applications.

Pancake Force Sensors normally provide a female thread thru the center and multiple thru holes on outer ring for mounting. Fixing the outside mounting holes will allow for it to be used in tension as well. Also by adding the tension base plate option users can utilize it in-line in both tension and compression, just like the S Beam Load Cell. Capacities ranges vary depending on the manufacturer, but Pancake Load Cells are generally offered from 50 lbs to 1 million lbs. Standard features typically include metric thread and quick disconnect. Fatigue rated Pancake Load Cells are also available and widely used in endurance testing applications. Submersible versions are also available with integrated cables. Some load cell manufacturers also offer built-in amplifiers with VDC/4-20mA or with TEDS per IEEE1451.4 option for plug & play. Pancake load Cells are the ideal weight sensor for load cell for tanks weighing system.

LCF Series - Universal Pancake Load Cell

LCF Series - Universal Pancake Load Cell LCF300 Universal Pancake Load Cell

LCF300 Universal Pancake Load Cell QLA133 Custom Pancake Load Cell w/ Built In Amplifier

QLA133 Custom Pancake Load Cell w/ Built In Amplifier LCF555 High Capacity Load Cell w/ Tension Base

LCF555 High Capacity Load Cell w/ Tension BaseVisit our Pancake Load Cell page to learn more!

Column Load Cell

Column Load Cells (also known as Canister Load Cell) offers compact design for high capacity compression applications such as CNC Machine Vise Clamping Force Test. These models offer robust construction with a capacity ranging from 2,000 to 30,000 lbs. FUTEK has also developed a miniature Load Cell Canister series for applications where size is a critical factor.

LCA Series - Miniature Column Load Cell Load Cell

LCA Series - Miniature Column Load Cell Load Cell LCA300 Miniature Column Load Cell

LCA300 Miniature Column Load Cell LCA310 Miniature Column Load Cell

LCA310 Miniature Column Load CellVisit our Column Load Cell page to learn more!

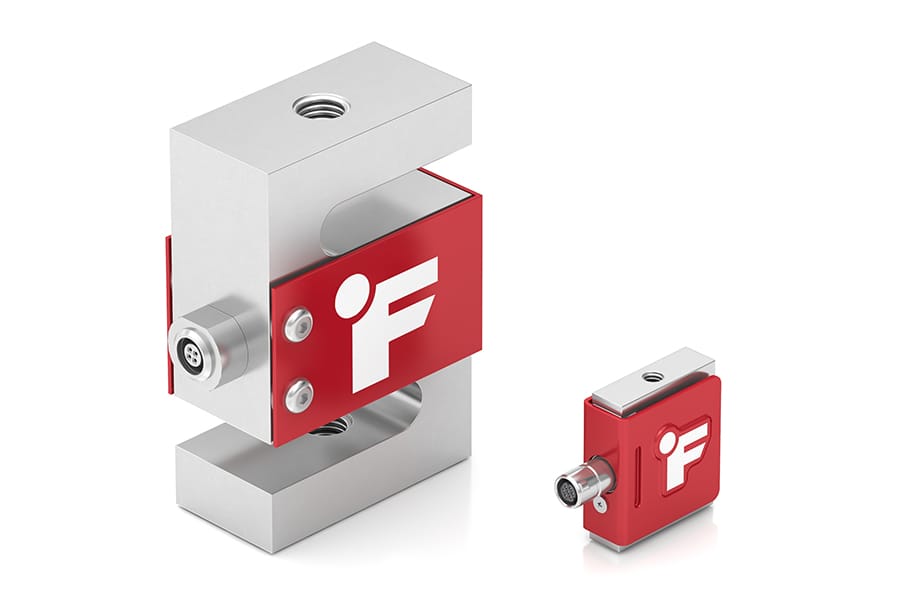

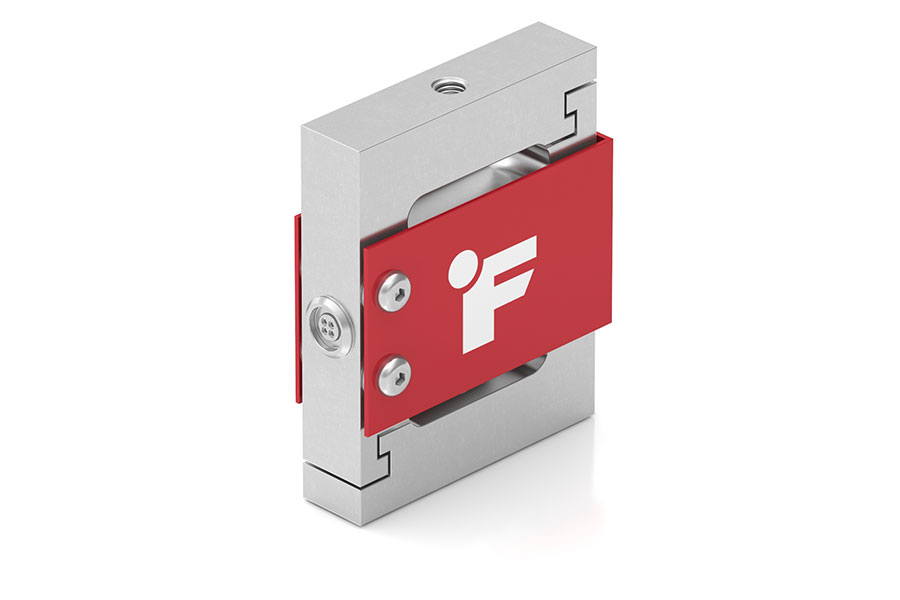

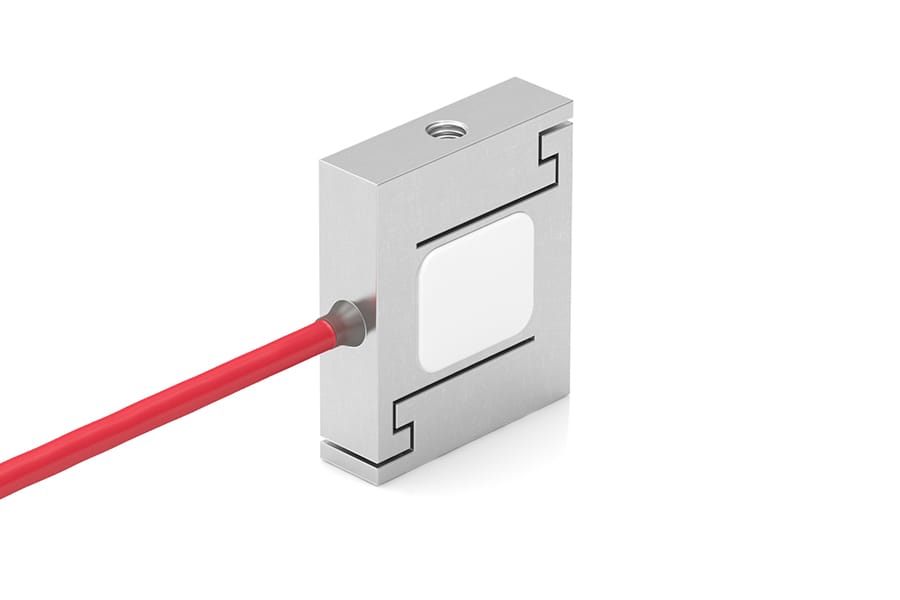

S Beam Load Cell

The S Beam Load Cell is one of the most popular types of load cells. It was originally designed for inline applications to convert mechanical scale to digital by replacing the spring or other in-line hardware. The S Beam Load Cell is available in variety of load ranges with both English & Metric threads. It is very popular due to its high precision, low price, and ease of installation. But since S Beam Force Sensors are strictly designed for in-line applications they are very sensitive to extraneous load, torque, and moments. Off center loading must be avoided for the best performance & longer service life. Please refer to the pancake type load cell for applications requiring off center loading or extraneous load, moment and torque capabilities.

Typical features of the S Beam Load Cell include an integrated cable or quick disconnect receptacle. S Beam Load Cells also come in full hermetic sealed versions and submersible types. In recent years, miniature versions of the S Beam Load Cell known as S Beam Load Cell Junior has also been designed and manufactured. The S Beam Load Cell Jr. (Miniature S Beam Load Cell) comes with effective built-in mechanical stop for overload protection in both Tension and Compression and is available from 10 grams full scale to 100 lbs. This innovative model comes in package sizes smaller than a quarter coin and is widely used in bag hanging medical applications during the dialysis process (load cell for dialysis), as well as other automated applications in which small package size is essential, making it a suitable load cell for dialysis.

LSB Series S Beam Load Cell

LSB Series S Beam Load Cell LSB302 Tension & Compression Load Cell

LSB302 Tension & Compression Load Cell LSB210 Miniature Submersible Load Cell

LSB210 Miniature Submersible Load Cell LSB205 Miniature S beam w/ PT-1000 Temperature Compensation

LSB205 Miniature S beam w/ PT-1000 Temperature CompensationVisit our S Type Load Cell page to learn more!

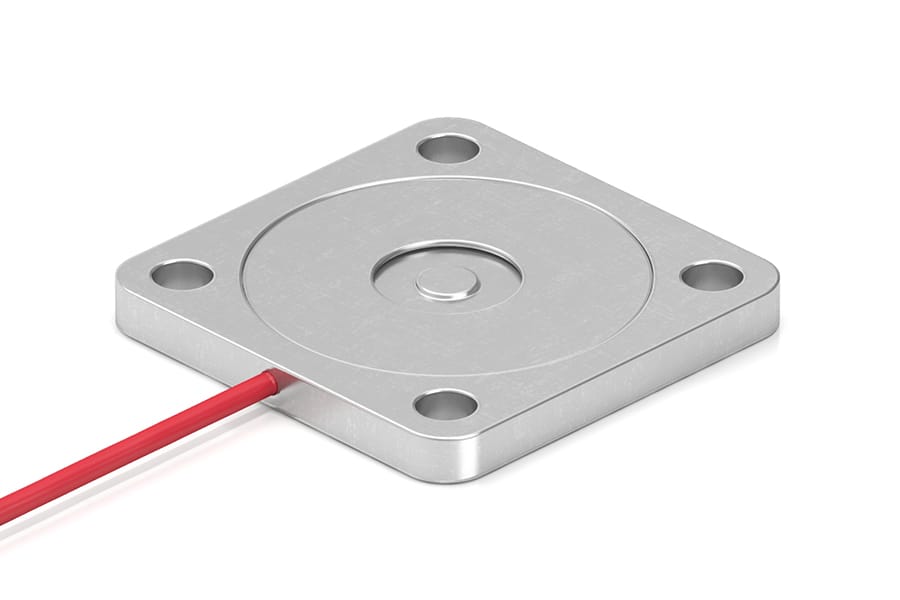

Load Button Load Cell

Load button load cells are designed for compression and known for their small package size. They are used in tight and limited spaces. General purpose ones are normally designed with diaphragm construction but some higher precision ones are designed with bending beams for low capacity and shear or column design for higher capacity. For best performance the load should be applied without the presence of any side load or torque. Mounting could be a challenge with standard load button load cells. To overcome this challenge, some models are available with mounting provision on the base. The ones without mounting provisions are normally retained by an outside wall or sandwiched between the assemblies. Some versions are also available with a threaded stud in the center for probe style loading.

Load button load cells are available in various capacities ranging from 1lb to 100,000 lbs and in packages ranging from ¼" (6mm) to 3" (76mm) OD. Load button force sensors are widely used in Medical applications as well as automation where small size is a must and space is limited. If space is not an issue and higher precision is required then use a pancake style load cell. Rolling element bearing load measurement is an application where load buttons are utilized.

LLB Series - Load Button Load Cells

LLB Series - Load Button Load Cells LLB500 High Capacity Load Button with Threaded Tapped Holes

LLB500 High Capacity Load Button with Threaded Tapped Holes QLA367 Custom Load Button with TEDS

QLA367 Custom Load Button with TEDS LLB390 Low Profile Load Button With Through Holes

LLB390 Low Profile Load Button With Through HolesVisit our Load Button Load Cell page to learn more!

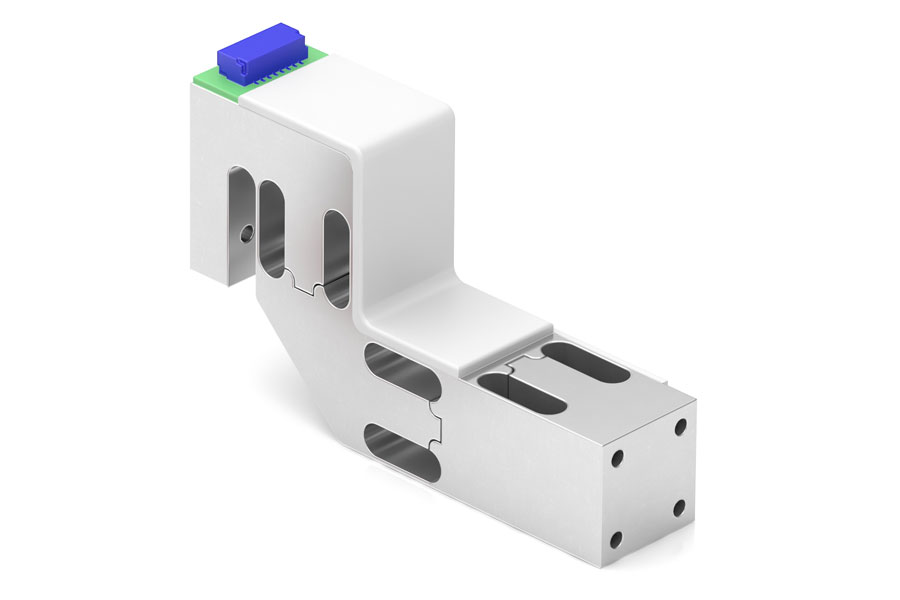

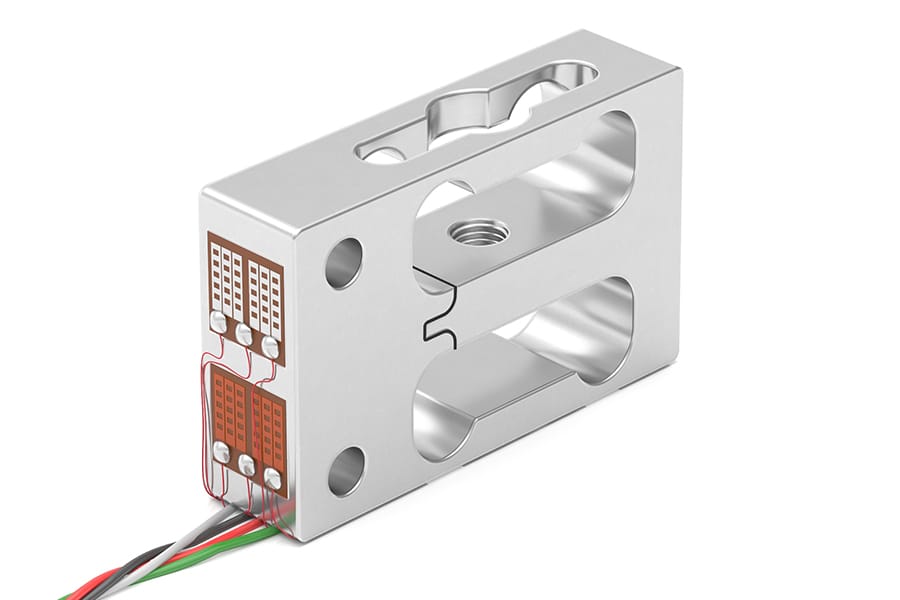

Single Point Load Cell

(Also known as Side Mount Load Cells, Parallelogram Sensors or Shear Beam Load Cells)

Single Point Load Cells are usually designed for processing applications which require weight control platforms, usually on the small scale type. They are given their name because they can be used for these platform applications supporting off center loading by utilizing only one sensor. The advantage of this particular load cell design over others is that it is low profile, has high precision, and can be adjusted for off center loading. This particular type of load cell is generally easy to mount. Other products for similar applications such as load buttons are not as easy to mount. This force sensor is also designed for high volume OEM applications and offered in a wide range of capacities from Gram ranges to 500 lbs in the same form fit function.

FUTEK's particular line of Single Point Force Sensors is more compact compared to the same product by other manufacturers. It averages in dimension about 2 × 0.5 × 2 inches compared to 4 × 1 × 3 inches. It also offers overload protection making it suitable for both process control and material testing applications since possible overload usually occurs during installation. Due to its size and precision it has widely been used in Handheld or portable equipment as well as many material testing machines. Other popular applications are in-line food processing or material process control or batching systems. Side mount load cells such as the LSM300 High Accuracy Load Cell model are a recommended OEM weight measurement solution for automatic bottle filling machines.

Also due to its compact size, high precision and long Mean Time Between Failure (MTBF of very well over 100 million cycles) it has been an ideal choice for many medical applications such as automated blood management system, dialysis and bag weighing applications for drug delivery application.

Visit our Single Point Load Cell page to learn more!

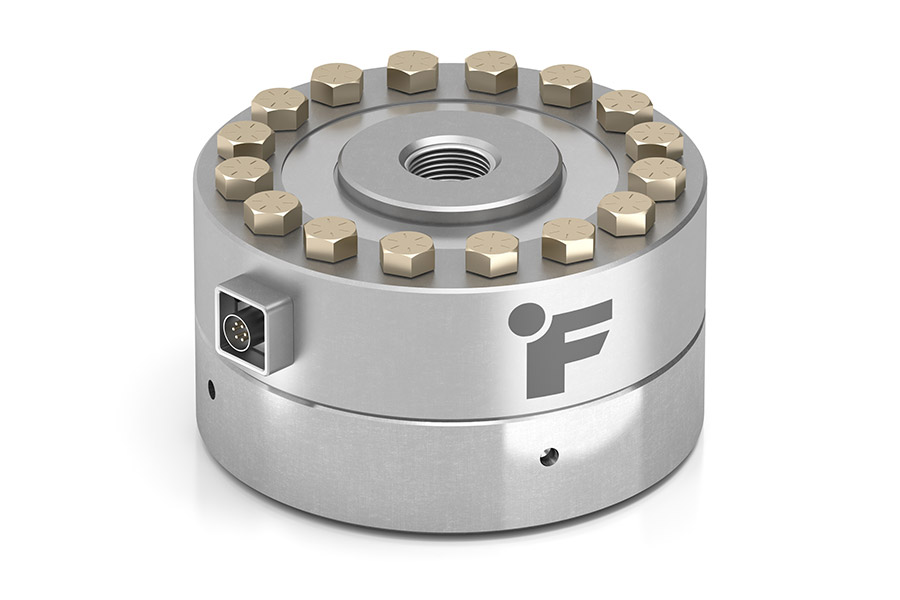

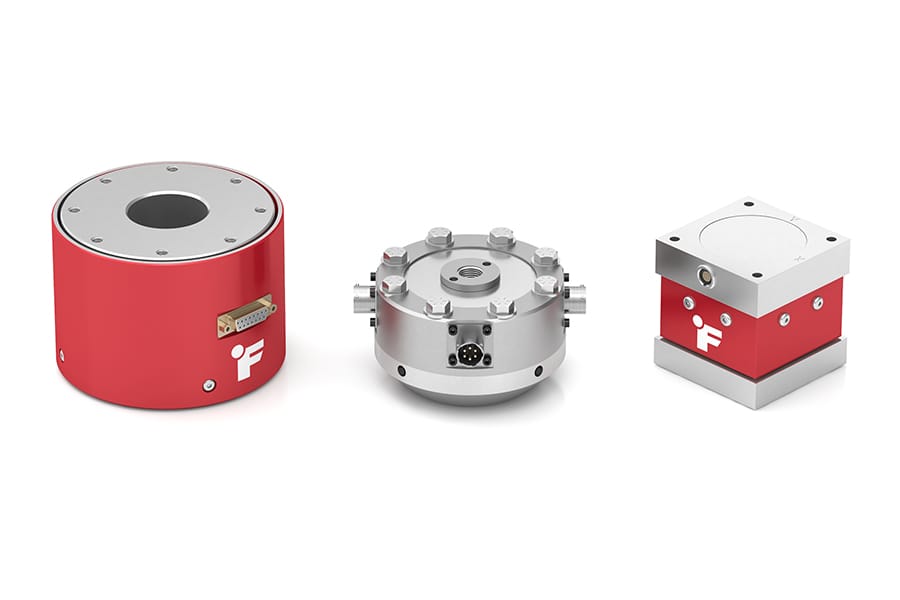

Multi Axis Load Cell

A Multi Component Sensor (also commonly known as force-torque sensor or multi component load cell) designed to measure in all spatial directions: forces in tension and compression (±Fx, ±Fy, and ±Fz) as well as torques or moments in clockwise and counterclockwise (±Mx, ±My or ±Mz).

These special force-torque sensors are equipped with multiple strain gage bridges that accurately measure the forces and torques applied in one direction with little or no cross-talk interference from force or moments applied in other directions.

In applications where multiple force and torque vectors must be measured simultaneously in x, y and z-directions, multi axis sensors are the preferable choices. Due to its compact design, multicomponent transducers save up a lot of space in the assembly and installation work time when compared to the alternate solution of installing multiple single axis load cells and/or torque sensors.

QMA147 - 3 Axis Load Cell with Overload Protection

QMA147 - 3 Axis Load Cell with Overload Protection MBA Series - Bi Axial Force Torque Sensor

MBA Series - Bi Axial Force Torque Sensor MAU Series - Stick Shift Bi Axial Load Cell

MAU Series - Stick Shift Bi Axial Load Cell MTA Series - Low Profile Thrust and moment Multi Axis Sensor

MTA Series - Low Profile Thrust and moment Multi Axis SensorVisit our Multi Axis Load Cell page to learn more!

How to choose a load cell for your application?

We understand that choosing the right load transducer is a daunting task, as there is no real industry standard on how you go about selecting load cells. There are also some challenges you may encounter, including finding the compatible amplifier or signal conditioner or requiring a custom product that would increase the product’s delivery time.

To help you select your force sensor, FUTEK developed an easy to follow, 5-Steps guide. Here is a brief summary to help you narrow down your choices. Check out our complete "How to Select a Load Cell?" guide for further information.

- Step 1: Understand your application and what you are measuring. Load sensors are different from pressure sensors or torque sensors and they are designed to measure tension and compression loads.

- Step 2: Define the sensor mounting characteristics and its assembly. Do you have static load or is it a dynamic type? Define the mounting type. How will you be mounting this Force Sensor?

- Step 3: Define your minimum and maximum capacity requirements. Be sure to select the capacity over the maximum operating load and determine all extraneous loads (side loads or off-center loads) and moments prior to selecting the capacity.

- Step 4: Define your size and geometry requirements (width, weight, height, length, etc) and mechanical performance requirements (output, nonlinearity, hysteresis, creep, bridge resistance, resolution, frequency response etc.) Other characteristics to consider include submersible (waterproof), cryogenic, high temperature, multiple or redundant bridges, and TEDS IEEE1451.4.

- Step 5: Define the type of output your application requires. Force transducer circuits outputs voltage in mV/V. So, if your PLC or DAQ requires analog output, digital output or serial communication, you will certainly need a load cell amplifier or signal conditioner. Some applications require a load cell indicator for local readout. Make sure to select the right amplifier as well as calibrate the entire measurement system (load transducer + signal conditioner). This turnkey solution translates into more compatibility and accuracy of the entire force measurement system.

For detailed information on our 5-Steps selection guide, take a look at our "How to choose a Load cell" complete guidelines.

LSM100 Fold Back Beam Load Cell

LSM100 Fold Back Beam Load Cell LSM250 (L2331) Parallelogram Load Cell

LSM250 (L2331) Parallelogram Load Cell LSM305 Parallelogram Load Cell

LSM305 Parallelogram Load Cell LSM306 Parallelogram Load Cell

LSM306 Parallelogram Load Cell