Load Cell - Load Cells | Load Cell Accessories | Load Cell Displays | Load Cell Instruments

Load Cells manufactured in US by FUTEK Advanced Sensor Technology (FUTEK), a leading manufacturer producing a huge selection of Load Cells, utilizing one of the most advanced technologies in the Sensor Industry: Metal foil strain gauge technology.

A Load Cell is defined as a transducer that converts an input mechanical force into an electrical output signal. Load Cells are also commonly known as Load Transducers or Load Sensors.

READ MOREMetal foil strain gauge based technology facilitates a design of a Load Cell through the following ‘Lehman’ described process (by department):

Selecting the proper load cell type for your application is a critical task as each load cell offers its own unique attributes. The following page will help clarify the different types of load cells available to you on our site and essentially guide you towards selecting the right load cell type.

Pancake Load Cell

Pancake Load Cells, also known as low profile Load Cells, are commonly used in applications that require high precision, and less sensitive to load condition. For most capacities the Pancake Load Cell is normally designed with multiple shear struts. For lower capacities it’s designed with bending beams. If properly designed and manufactured, the nature of its structure is less sensitive to extraneous load and moments (especially Torque) compared to other inline sensors such as the S Beam Load Cell, diaphragm or column type. This type of Load Cell is normally used in press in compression for controlling the applied load or pressure during the test or production.

Pancake Load Cells normally provide a female thread thru the center and multiple thru holes on outer ring for mounting. Fixing the outside mounting holes will allow for it to be used in tension as well. Also by adding the tension base plate option users can utilize it in-line in both tension and compression, just like the S Beam Load Cell. Capacities ranges vary depending on the manufacturer, but Pancake Load Cells are generally offered from 50 lbs to 1 million lbs. Standard features typically include metric thread and quick disconnect. Fatigue rated Pancake Load Cells are also available and widely used in endurance testing applications. Submersible versions are also available with integrated cables. Some manufacturers also offer built-in amplifiers with VDC/4-20mA or with TEDS per IEEE1451.4 option for plug & play.

Types of Pancake Load Cells

View all our Pancake Load Cells

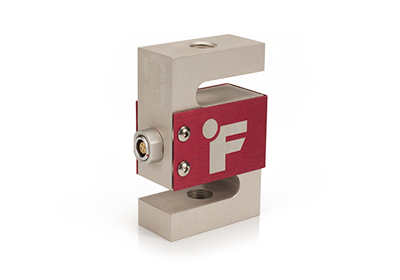

S Beam Load Cell

The S Beam Load Cell, also known as the Z Beam Load Cell, is one of the most popular types of load cells. It was originally designed for inline applications to convert mechanical scale to digital by replacing the spring or other in-line hardware. The S Beam Load Cell is available in variety of load ranges with both English & Metric threads. It is very popular due to its high precision, low price, and ease of installation. But since S Beam Load Cells are strictly designed for in-line applications they are very sensitive to extraneous load, torque, and moments. Off center loading must be avoided for the best performance & longer service life. Please refer to the pancake type load cell for applications requiring off center loading or extraneous load, moment and torque capabilities.

Typical features of the S Beam Load Cell include an integrated cable or quick disconnect receptacle. S Beam Load Cells also come in full hermetic sealed versions and submersible types. In recent years, miniature versions of the S Beam Load Cell known as S Beam Load Cell Junior has also been designed and manufactured. The S Beam Load Cell Jr. (Miniature S Beam Load Cell) comes with effective built-in mechanical stop for overload protection in both Tension and Compression and is available from 10 grams full scale to 100 lbs. This innovative model comes in package sizes smaller than a quarter coin and is widely used in bag hanging medical applications during the dialysis process, as well as other automated applications in which small package size is essential.

View all our S Beam Load Cells

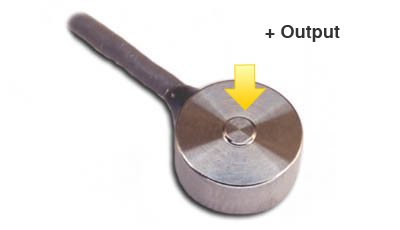

Load Button

Load button load cells are designed for compression and known for their small package size. They are used in tight and limited spaces. General purpose ones are normally designed with diaphragm construction but some higher precision ones are designed with bending beams for low capacity and shear or column design for higher capacity. For best performance the load should be applied without the presence of any side load or torque. Mounting could be a challenge with standard load button load cells. To overcome this challenge, some models are available with mounting provision on the base. The ones without mounting provisions are normally retained by an outside wall or sandwiched between the assemblies. Some versions are also available with a threaded stud in the center for probe style loading. Load button load cells are available in various capacities ranging from 1lb to 100,000 lbs and in packages ranging from ¼” (6mm) to 3” (76mm) OD. Load button load cells are widely used in Medical applications as well as automation where small size is a must and space is limited. If space is not an issue and higher precision is required then use a pancake style load cell.

View all our Load Button Load Cells

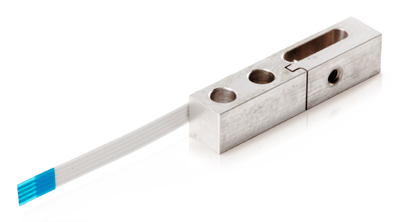

Single Point Load Cell - (Also known as Side Mount Load Cells, Parallelogram Sensors or Belt Buckle Sensors)

Single Point Load Cells are usually designed for processing applications which require weight control platforms, usually on the small scale type. They are given their name because they can be used for these platform applications supporting off center loading by utilizing only one sensor. The advantage of this particular load cell design over others is that it is low profile, has high precision, and can be adjusted for off center loading. This particular load cell type is generally easy to mount. Other products for similar applications such as load buttons are not as easy to mount. This load cell is also designed for high volume OEM applications and offered in a wide range of capacities from Gram ranges to 500 lbs in the same form fit function.

FUTEK’s particular line of Single Point Load Cells is more compact compared to the same product by other manufacturers. It averages in dimension about 2 x 0.5 x 2 inches compared to 4x1x3 inches. It also offers overload protection making it suitable for both process control and material testing applications since possible overload usually occurs during installation. Due to its size and precision it has widely been used in Handheld or portable equipment as well as many material testing machines. Other popular applications are in-line food processing or material process control or batching systems.

Also due to its compact size, high precision and long Mean Time Between Failure (MTBF of very well over 100 million cycles) it has been an ideal choice for many medical applications such as automated blood management system, dialysis and bag hanging applications for drug delivery application.

View all our Single Point Load Cells

- A Load Cell ‘flexure,’ a physical unit comprised of high strength materials, is designed and fabricated by FUTEK Advanced Sensor Technologies Engineering Team and In-House Machine shop, respectively.

- Metal foil strain gauges are then bonded to a diaphragm or most sensitive area of physical design by FUTEK Advanced Sensor Technology’s Lamination Department.

- The Metal foil strain gauge Wheatstone bridge configuration is then wired by our specialized department while accounting for temperature compensation affects of the transducer/sensor.

- When Our NIST Traceable Calibration Department applies a mechanical load, a weight of tension or compression direction, the strain gauge then does its magic by capitalizing in this mechanical deformation and thus producing an electrical resistance change proportional to the load.

- The Highest accuracy which may conform to many standards from the Automotive to Aerospace.

- Robust Construction made of either high strength Stainless steel or Aluminum.

- A guarantee to perform at longest possible work life even at the most rigorous conditions

- A plethora of mounting options for ANY scale ANY-where.

- Competitive pricing that separates FUTEK Advanced Sensor Technology from the rest.

- A full gamut of selections with capacities ranging from 10 grams to 1 MILLION pounds.

From submersible to space, FUTEK Advanced Sensor Technology Load Cells cover an array of applications in many industries ranging from Medical, Automotive, Aviation, Aerospace, Computer, Textile, Material Testing, Process Control, and Robotic & Automation just to name a few.

FUTEK Advanced Sensor Technology’s industry listing is as broad as its Sensor selection. Our selection of Load Cells can be categorized by the following styles:- Automotive Load Cell (i.e. auto test measure devices: pedal, shifting, multi axial)

- Bending Beam Load Cell (measures force, pressure, and displacement)

- Column/Canister Load Cell (conventional and miniature column designs for compression measurement)

- Donut Load Cell (Tension or compression, designed for space limited clamp force measurement)

- Fold Back Beam Load Cell (Compact precision bending beams designed for OEM applications)

- Force Sensor (Economical OEM bending beam designed for force, pressure, and displacement)

- Load/Force Washer Load Cell (Compact hollow design for fastener clamp force measurement).

- Load Button (compression only designed for space limited applications)

- Medical Related Load Cells (Rehab force measurements, OEM bending beams, multi axis sensors)

- Overload Protection (designed to help protect sensors from accidental and or excess forces)

- Pancake Load Cells (Low profile, high precision, tension or compression Load Cell)

- S Beam/ Z beam Load Cells (Inline Load Cell, primarily for tension measurement)

- Thread female mount Load Cells (various tension or compression internal thread mount Load Cell)

- Thread male mount Load Cells (various tension or compression stud mount threaded Load Cell)

- Thru hole Load Cells (Tension or compression, designed for space limiting clamp force measurement)

Load Cell Types

Selecting the proper load cell type for your application is a critical task as each load cell offers its own unique attributes. The following page will help clarify the different types of load cells available to you on our site and essentially guide you towards selecting the right load cell type.

Pancake Load Cell

Pancake Load Cells, also known as low profile Load Cells, are commonly used in applications that require high precision, and less sensitive to load condition. For most capacities the Pancake Load Cell is normally designed with multiple shear struts. For lower capacities it’s designed with bending beams. If properly designed and manufactured, the nature of its structure is less sensitive to extraneous load and moments (especially Torque) compared to other inline sensors such as the S Beam Load Cell, diaphragm or column type. This type of Load Cell is normally used in press in compression for controlling the applied load or pressure during the test or production.

Pancake Load Cells normally provide a female thread thru the center and multiple thru holes on outer ring for mounting. Fixing the outside mounting holes will allow for it to be used in tension as well. Also by adding the tension base plate option users can utilize it in-line in both tension and compression, just like the S Beam Load Cell. Capacities ranges vary depending on the manufacturer, but Pancake Load Cells are generally offered from 50 lbs to 1 million lbs. Standard features typically include metric thread and quick disconnect. Fatigue rated Pancake Load Cells are also available and widely used in endurance testing applications. Submersible versions are also available with integrated cables. Some manufacturers also offer built-in amplifiers with VDC/4-20mA or with TEDS per IEEE1451.4 option for plug & play.

Types of Pancake Load Cells

S Beam Load Cell

The S Beam Load Cell, also known as the Z Beam Load Cell, is one of the most popular types of load cells. It was originally designed for inline applications to convert mechanical scale to digital by replacing the spring or other in-line hardware. The S Beam Load Cell is available in variety of load ranges with both English & Metric threads. It is very popular due to its high precision, low price, and ease of installation. But since S Beam Load Cells are strictly designed for in-line applications they are very sensitive to extraneous load, torque, and moments. Off center loading must be avoided for the best performance & longer service life. Please refer to the pancake type load cell for applications requiring off center loading or extraneous load, moment and torque capabilities.

Typical features of the S Beam Load Cell include an integrated cable or quick disconnect receptacle. S Beam Load Cells also come in full hermetic sealed versions and submersible types. In recent years, miniature versions of the S Beam Load Cell known as S Beam Load Cell Junior has also been designed and manufactured. The S Beam Load Cell Jr. (Miniature S Beam Load Cell) comes with effective built-in mechanical stop for overload protection in both Tension and Compression and is available from 10 grams full scale to 100 lbs. This innovative model comes in package sizes smaller than a quarter coin and is widely used in bag hanging medical applications during the dialysis process, as well as other automated applications in which small package size is essential.

Load Button

Load button load cells are designed for compression and known for their small package size. They are used in tight and limited spaces. General purpose ones are normally designed with diaphragm construction but some higher precision ones are designed with bending beams for low capacity and shear or column design for higher capacity. For best performance the load should be applied without the presence of any side load or torque. Mounting could be a challenge with standard load button load cells. To overcome this challenge, some models are available with mounting provision on the base. The ones without mounting provisions are normally retained by an outside wall or sandwiched between the assemblies. Some versions are also available with a threaded stud in the center for probe style loading. Load button load cells are available in various capacities ranging from 1lb to 100,000 lbs and in packages ranging from ¼” (6mm) to 3” (76mm) OD. Load button load cells are widely used in Medical applications as well as automation where small size is a must and space is limited. If space is not an issue and higher precision is required then use a pancake style load cell.

| FUTEK Products For This Application | |||

|

|

|

|

| LLB200 Subminiature Load Button | LLB300 Subminiature Load Button | LLB400 Load Button Load Cell |

LLB500 LoadButton Load Cell |

Single Point Load Cell - (Also known as Side Mount Load Cells, Parallelogram Sensors or Belt Buckle Sensors)

Single Point Load Cells are usually designed for processing applications which require weight control platforms, usually on the small scale type. They are given their name because they can be used for these platform applications supporting off center loading by utilizing only one sensor. The advantage of this particular load cell design over others is that it is low profile, has high precision, and can be adjusted for off center loading. This particular load cell type is generally easy to mount. Other products for similar applications such as load buttons are not as easy to mount. This load cell is also designed for high volume OEM applications and offered in a wide range of capacities from Gram ranges to 500 lbs in the same form fit function.

FUTEK’s particular line of Single Point Load Cells is more compact compared to the same product by other manufacturers. It averages in dimension about 2 x 0.5 x 2 inches compared to 4x1x3 inches. It also offers overload protection making it suitable for both process control and material testing applications since possible overload usually occurs during installation. Due to its size and precision it has widely been used in Handheld or portable equipment as well as many material testing machines. Other popular applications are in-line food processing or material process control or batching systems.

Also due to its compact size, high precision and long Mean Time Between Failure (MTBF of very well over 100 million cycles) it has been an ideal choice for many medical applications such as automated blood management system, dialysis and bag hanging applications for drug delivery application.

| FUTEK Products For This Application | |||

|

|

|

|

| LSM200 (L2341) Fold Back Beam Load Cell |

LSM250 (L2331) Parallelogram Load Cell |

LSM300 (L2330) Parallelogram Load Cell |

LSM400 (L1900) Mini Beam Load Cell |